IF 1897 • 10/19 Copyright © 2019, Eaton’s Crouse-Hinds Division Page 3

A

B

165.1

6.50

197.2

7.22-7.89

164.3

6.47

A

B

NOTES:

1. PLACE PARTS IN BAG AND LABEL

HEAT TREATMENT:

REDRAWN DATE

ORIGINAL DATE

UNLESS OTHERWISE SPECIFIED

TOLERANCES

APPROVED BY

MATERIAL:

FINISH:

PATT. I.B.

APPROVED BY

CHECKED BY

DRAWN BY

USED ON

APPLICATION

NEXT ASSY.

DIR NUMBER:

TITLE

CODE IDENT. NO.

SIZE

REV.

CC

HSY

-Templat

e-

D

SW_REV 08/201

3

DO NO

T SCALE DRA

WING

D

1020306691///

07/02/2014

T. DALY

DRT

PSB

PIPE MOUNT KIT, S/A

(PMKIT)

FIRST MADE FOR

MLL

0306691

X1

SCALE 2:1

WT. 0.50 LB

SHEET 1 OF 2

THIS IS PROPERTY OF EATON AND CONTAINS CONFIDENTIAL

AND TRADE SECRET INFORMATION. POSSESSION DOES NOT

CONVEY ANY RIGHTS TO LOAN, SELL OR DISCLOSE SAID

INFORMATION. REPRODUCTION OR USE FOR ANY PURPOSE

OTHER THAN WHICH IT WAS SUPPLIED MAY NOT BE MADE

WITHOUT EXPRESS WRITTEN PERMISSION OF EATON.

THIS DRAWING IS ON LOAN AND IS TO BE

RETURNED UPON REQUEST.

IB

.X

.XX

ANGLES

.XXX

±

± .005

± .01

±

1.5 °

in.

mm

.13

1.5 °

± .3

±

±

±

NOTES:

1.

THIRD ANGLE PROJECTION

A

B

C

D

1

2

3

4

5

6

7

8

A

D

C

B

8

7

6

5

4

3

2

1

UNLESS OTHERWISE SPECIFIED, ALL

PRIMARY DIMENSIONS ARE IN

INCHES. DIMENSIONS IN [ ] ARE IN

MILLIMETERS.

9

10C01-025D20

SCREW, HEX HD, 1/20 x 5/8"

2

8

11A12-025D

WASHER, LOCK, SPRING, 1/4"

2

7

10K01-031D

NUT, HEX, 5/16-18

3

6

11A12-031D

WASHER, LOCK, SPRING, 5/16"

3

5

10C01-031D32

SCREW, HEX HD, 5/16-18 x 1"

2

4

10C01-031D20

SCREW, HEX HD, 5/16-18 x 5/8"

1

3

0306682-2

DURA PRO BACK MOUNT

1

2

0903016

PIPE CLAMP, UPPER

1

1

0903015

PIPE CLAMP, LOWER

1

ITEM

NO.

DWG NUMBER

DESCRIPTION

QTY

CLAMP SIZE

(mm)

MATERIAL

CLAMP,

UPPER PART

NO.

CLAMP,

LOWER PART

NO.

42

SS - 316

CHR5227

CHR5236

SS - 304

CHR5228

CHR5237

STL, ZNC PLTNG

CHR5229

CHR5238

51

SS - 316

CHR5230

CHR5239

SS - 304

CHR5231

CHR5240

STL, ZNC PLTNG

CHR5232

CHR5241

60

SS - 316

CHR5233

CHR5242

SS - 304

CHR5234

CHR5243

STL, ZNC PLTNG

CHR5235

CHR5244

CONFIGURATION

DIMENSION (INCHES)

A

B

C [mm]

D

DIAMETER 60

4.331

3.543

2.36

60

1.693

DIAMETER 51

3.740

2.953

2.01

51

1.535

DIAMETER 42

3.386

2.598

1.65

42

1.378

Ø C

A

D

B

Side

Channel

Clamp

1/4 Set Screw

5/16 Screw

Configuration

Dimension (inches)

A

B

C

D

PM Kit 2.0

(trade size 2”)

4.331

3.543

2.36

1.693

PM Kit 1.5

(trade size 1-1/2”)

3.740

2.953

2.00

1.535

PM Kit 1.25

(trade size 1-1/14”)

3.386

2.598

1.65

1.378

Length

(in)

(mm)

A

44.6

1133

B

18-41.6

610-1056

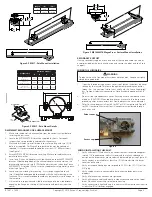

Figure 5. PM KIT - Pole Mount Installation

Figure 6. PM KIT - Pole Mount Details

D. MP1054MTK MAGNAPRO OR SURFACE MOUNT

1. Make sure the power is disconnected from the conduit system before

installing the luminaire.

2. Locate the MP1054MTK Kit brackets supplied in the kit. For retrofit,

inspect the existing brackets and replace if necessary.

3. Mark and drill holes to install brackets to wall or ceiling with two (2) 1/4”

bolts (not supplied). For MagnaPro, bracket holes may be spaced as

required, it is recommended to keep them at least 12” (305mm) apart

(see Figure 7).

4. Attach MP1054MTK kit brackets to ceiling. Make sure the brackets are

parallel to each other.

5. Install one (1) channel adapter with slide channel onto each MP1054MTK

bracket. Slide the long edge of the channel adapter into the slots on the

bracket and tighten the two (2) Phillips head screws on the ends of each

MP1054MTK kit bracket. Make sure the slide brackets are parallel to each

other (see Figure 7).

6. Luminaire is now ready for mounting. It is strongly suggested to use

two (2) qualified tradespeople to proceed with the final mounting of the

luminaire. This is recommended to avoid any personal injury or damage to

the luminaire.

7. Lift luminaire into position and slide the luminaire into the slide brackets,

engaging the flange on the top of the luminaire and position it near the

center.

Figure 7. MP1054MTK MagnaPro or Surface Mount Installation

SECONDARY SUPPORT

If using secondary support, attach one end of the support cable to a corner

eyelet provided on the luminaire housing and secure the other end to a fixed

support.

WIRING THE LUMINAIRE

1. Open the threaded wiring access cover (see Figure 8) and allow the cover

to hang by the lanyard. Terminate the equipment grounding conductor

(green) first, the common (white) next, and finally, the line voltage (black)

last. Tighten all electrical connections. Note -Standard openings are 3/4”

NPT.

2. Re-install the threaded access cover. Ensure gasket is seated and clean

of debris. (CAUTION: When replacing cover, make sure that there are no

protruding wires or connectors that would obstruct the status indicator.

3. Refer to wiring diagram in Figure 9 for RV1 or AV1 luminaire and Figure10

for RAV1 luminaire. Maximum four (4) conductors are allowed through

each entry hub.

WARNING

To reduce the risk of ignition of hazardous atmospheres, keep cover tightly

closed during operation.

!

Driver cover

Access cap

Figure 8

WIRING INSTALLATION CHECKLIST

1. Verify sufficient HTL Lubricant is on conduit entries (recommend approx-

imately 1/8” bead around the first thread) and that all unused conduit

entries on the driver cover are closed with lubricated plugs (see Figure 8).

2. Verify conduit is installed for at least five (5) full threads into the driver

cover conduit entries.

3. Verify installed conduit plugs are torqued to 42-52 ft.-lbs. (57-71 N-m) for

3/4” plug.

4. Verify supply wires are connected to luminaire wire leads per wiring

diagrams.

5. Verify all electrical connections are tightened.

6. Verify all wires are safely and neatly inside access cap and not on top of

driver. Re-attach access cap to luminaire housing.

7. Verify access cap is tight and cap is in contact with luminaire housing with

at least five (5) full threads engaged.

327

12.88

241.3

9.50

158.7

6.25

295.4

11.63

A

B

B

A