2

5HP INLINE PUMP MANUAL REV030921

SAFTEY INFORMATION

This manual contains very important information to know and understand. This is to provide for SAFTEY and to PREVENT

EQUIPMENT PROBLEMS. To help understand this information, observe the following:

DANGER:

Danger indicates and imminently hazardous situation which, if not avoided, will result in death or

serious injury.

WARNING

:

Warning indicates a potentially hazardous situation which if not avoided, could result in death or serious

injury.

CAUTION:

Caution indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury.

NOTICE:

Notice indicates important information, that if not followed, may cause damage to equipment.

CALIFORNIA PROPOSITION 65

WARNING:

This product or its power cord may contain chemicals known to the state of California to cause cancer

and birth defects or other reproductive harm. Wash hands after handling.

1.

Allow only trained, authorized persons who have read and understood these operating instructions to use this

equipment. Failure to follow the instructions, procedures and safety precautions in this manual can result in

accidents and injuries.

2.

NEVER start or operate the pump under unsafe conditions. Tag the compressor, disconnect, and

lock out all power to it to prevent accidental start-up until the condition is corrected.

3.

Install, use, and operate the pump only in full compliance with all pertinent OSHA regulations and

all applicable Federal, State & Local codes, standards, and regulations.

4.

Keep a first aid kit in a convenient place. Seek medical assistance promptly in case of injury. Avoid

infection by caring for any small cuts and burns promptly.

BREATHABLE AIR

1.

NEVER

use air from this pump for breathable air except in full compliance with OSHA Standards 29 CFR

1910 and any other Federal, State or Local codes or regulations

.

2.

DO NOT

use airline anti-icer systems in air lines supplying respirators or other equipment used to produce

breathable air.

DO NOT

discharge air from these systems in unventilated or other confined areas.

3.

DO NOT

use airline anti-icer systems in airlines supplying respirators or other equipment used to produce

breathable air.

DO NOT

discharge air from these systems in unventilated or confined areas.

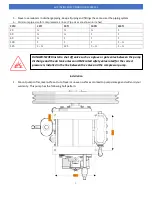

DANGER: Death or serious injury can result from inhaling compressed air

without using proper safety equipment. See OSHA standards on safety.

Содержание 5HP

Страница 1: ...APP2I0524TP 5HP INLINE PUMP MANUAL REV030921...

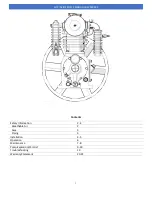

Страница 10: ...9 5HP INLINE PUMP MANUAL REV030921 Pump Explosion Parts List...

Страница 11: ...10 5HP INLINE PUMP MANUAL REV030921...

Страница 12: ...11 5HP INLINE PUMP MANUAL REV030921...

Страница 13: ...12 5HP INLINE PUMP MANUAL REV030921...

Страница 14: ...13 5HP INLINE PUMP MANUAL REV030921...

Страница 15: ...14 5HP INLINE PUMP MANUAL REV030921...

Страница 16: ...15 5HP INLINE PUMP MANUAL REV030921...

Страница 17: ...16 5HP INLINE PUMP MANUAL REV030921...

Страница 18: ...17 5HP INLINE PUMP MANUAL REV030921...

Страница 19: ...18 5HP INLINE PUMP MANUAL REV030921...