8

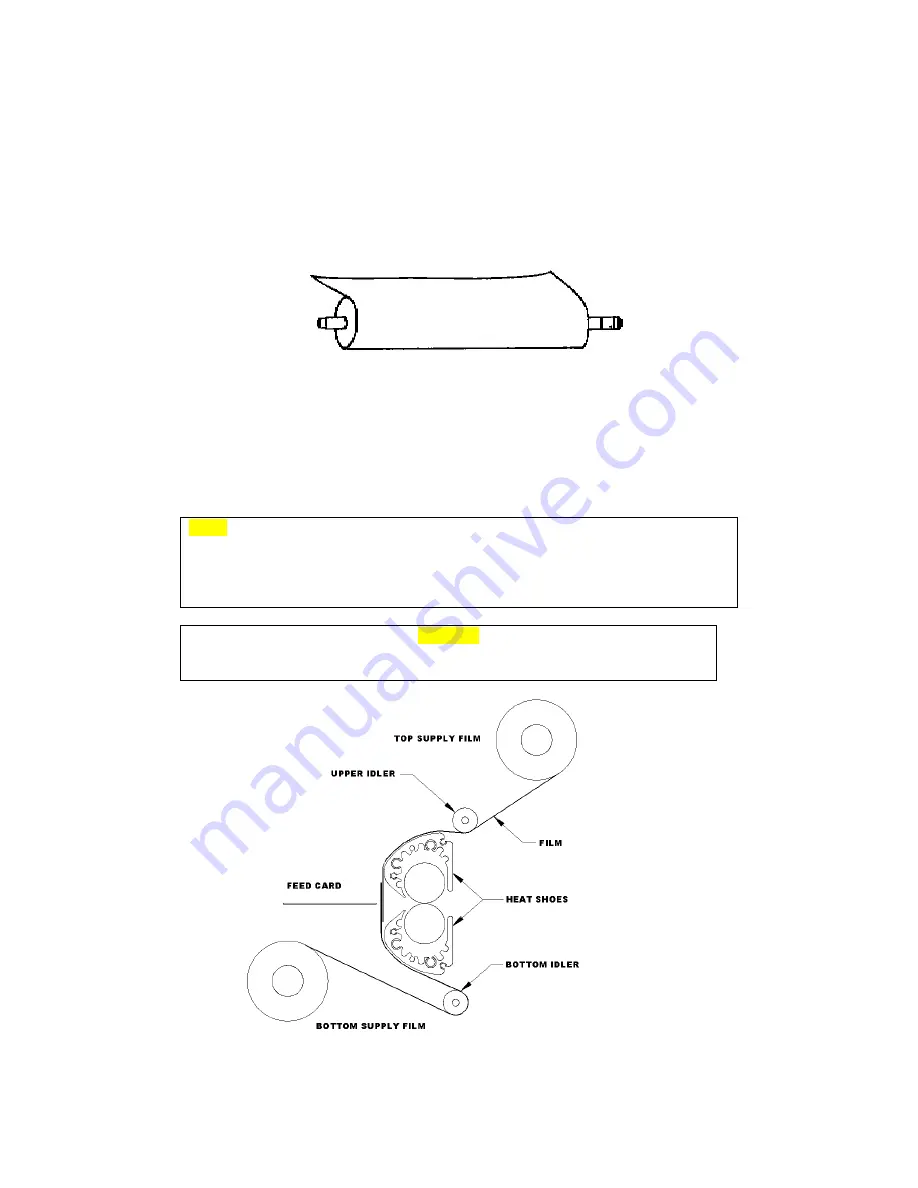

2. Pull 6"-12" of film from the top roll. Pass the film under the idler bar and over the heat shoes.

Make sure the shiny side of the film is against the shoes.

3. For the bottom supply roll, remove the run-off table. From the back of the laminator, place the

mandrel ends into position in the lower mandrel holder slots. Return the Run-off Table to its

proper position before operating the laminator. If you are at the back of the laminator the film

should unwind away from you at the top of the roll as in Figure 4 below.

Figure

4

4. Pull 6"-12" of film from the bottom roll. Pass it under the lower idler bar and drape the film from

the bottom roll over the film from the top roll. Since the heat shoes are hot the bottom film will

adhere to the top film. See Figure 5 below.

Note:

The shiny side of the film must always go against the Heat Shoes. If the

laminating film is wound with the dull side out, the Lower Idler Bar must be

moved to the lower position. To do this, remove the side covers and loosen the

screws from both ends of the Idler Bar. Move the bar to the lower position and

tighten both screws. Replace the side covers.

Caution:

The Heat Shoes reach a temperature of up to 350°F.

Do not touch the surface of the Heat Shoes.

Figure 5

Содержание BA-EZ27g

Страница 1: ...Easy Lam green BA EZ27g Roll Laminator...