SPINDLE AND SUPPORT ARM “TEE” BEAM ASSEMBLY [H] & [D] TO

MAIN SUPPORT FRAME & SPINDLE SUPPORT ASSEMBLY [A] & [E].

1.

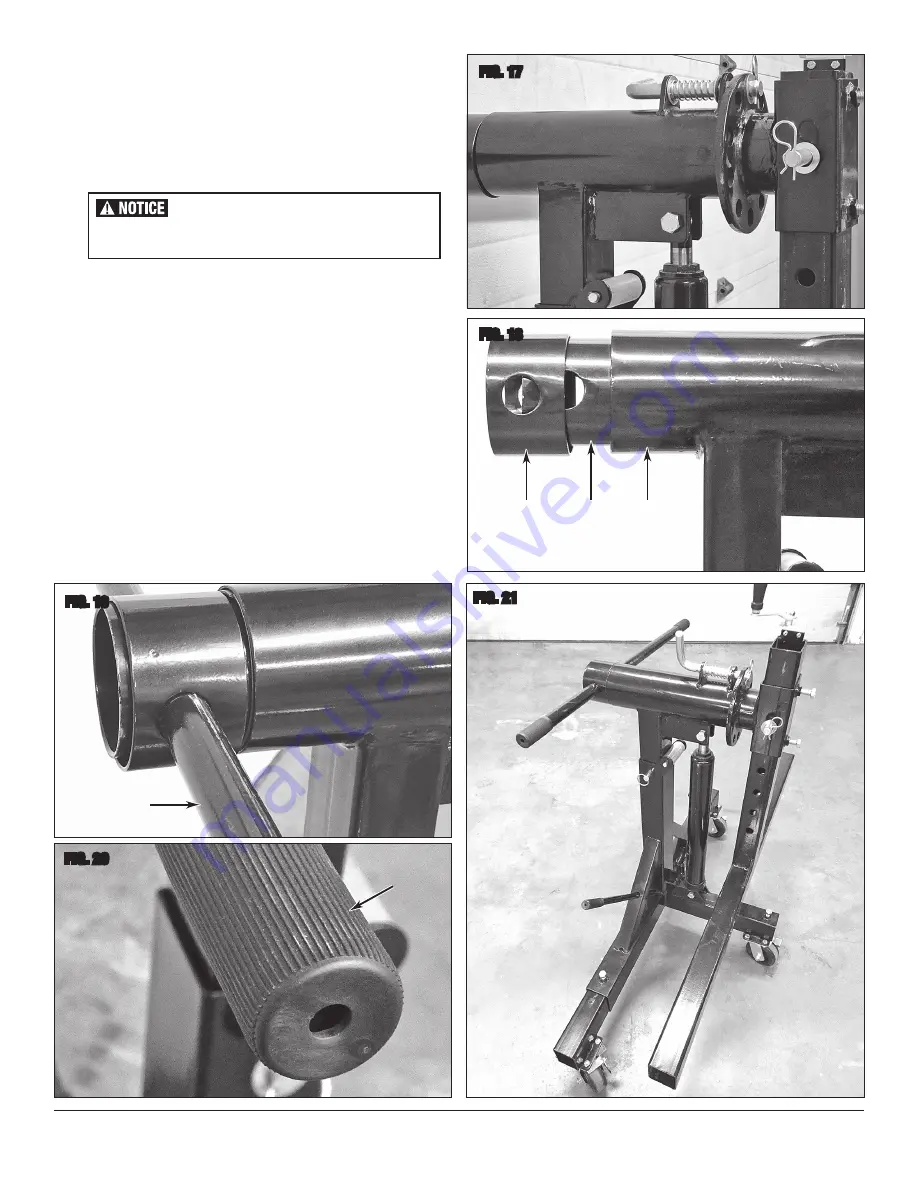

Remove the Retaining Clip and Washer from the Spindle Latch Pin and

set aside for reinstallation.

2.

Apply a liberal amount of high-quality synthetic, high-load wheel

bearing grease or an anti-seize compound to the bearing surfaces of

the Spindle Support and outside of the Spindle before insertion.

3.

Lift the Spindle and “Tee” Beam Assembly

[H]

and

[D]

and insert the

Spindle into the Sleeve. Push it in fully engaging the Latch Pin with the

hole nearest the 12:00 position of the 10 in the Rotation Lock Plate

(FIG 17)

.

4.

Reinstall the previously removed Retaining Clip and Washer onto the

Spindle Latch Pin

(FIG 17)

.

5.

Slide the Spindle Retaining Collar

[J]

over the protruding inboard end

of the Spindle

[H]

and align the through holes

(FIG 18)

.

6.

Insert the Spindle Rotating Bar

[K]

through the Spindle Retaining

Collar

[J]

and the Spindle

[H] (FIG 19)

.

7.

Push the rubber Spindle Rotating Bar Grips

[L]

fully onto the ends of

the Spindle Rotating Bar

[K] (FIG 20)

.

8.

The assembly should appear as in

FIG 21

. Repeat assembly procedure

for opposite end.

To order parts and supplies: 800.343.9353 >> eastwood.com

9

The assistance of a capable assistant is required for

the following step.

FIG. 17

FIG. 18

FIG. 19

FIG. 20

FIG. 21

E

✓

✓

✓

H

J

✓

K

L

✓