4

Eastwood Technical Assistance: 800.343.9353 >> [email protected]

EYE INJURY HAZARD!

Rapidly reciprocating Blades will eject sharp metal chips out of the front at

high velocity. Always wear ANSI approved eye protection when operating

this tool.

DO NOT attempt to exceed 18 Gauge (0.050”) [1.2mm] mild steel, aluminum

and copper or 20 Gauge Maximum (0.036”) [0.91mm] for stainless steel.

POSITIONING CUTTING HEAD

The Cutting Head may be rotated 360° in relation

to the Handle of the Shear Body to accommodate

cutting in difficult to reach areas. To do so:

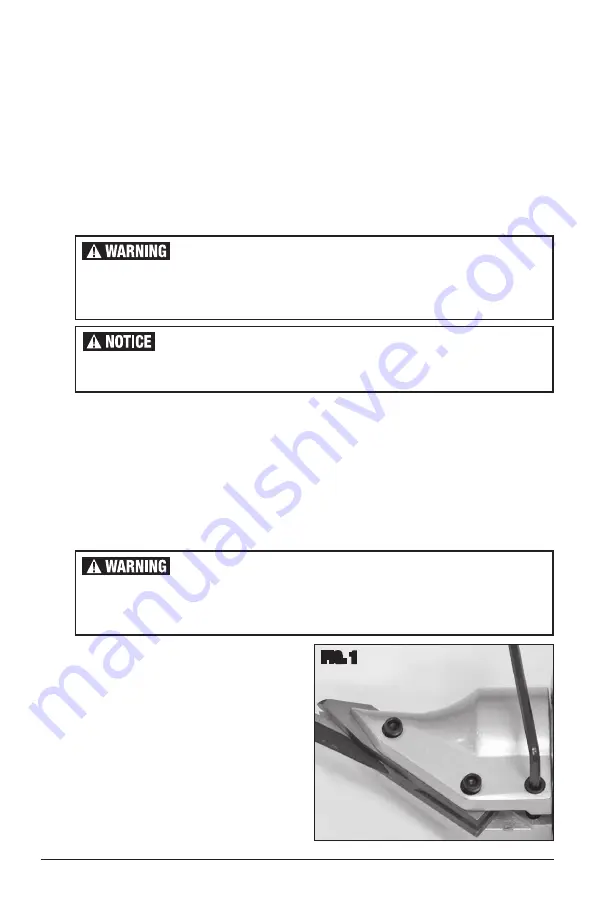

• Using the included 4 mm Hex Key, loosen

(but do not remove) the three socket head

cap screws on the Cutting Head adequately

to release clamping pressure

(FIG 1).

• Rotate the Cutting Head about the axis of

the Shear Body to the desired position then

re-tighten the three screws.

SET-UP & CONNECTION

• Be sure that the air supply to the tool is clean and dry. Moisture in the supply line will quickly

damage the motor and valves.

• A minimum 3/8” I.D. air line should be used for optimal performance.

• Thread the included 1/4” Male Quick-Disconnect Fitting into the air inlet of the tool using a

quality thread sealing tape (not included).

OPERATION

• Place the cutting blades against work piece and depress trigger to actuate cutting.

• Always maintain a firm grip while operating tool, do not force but allow the reciprocating action

of the Cutting Blade to do the work.

• Be sure that the workpiece is clamped down or held securely to minimize the danger of injury

while operating tool.

INJURY HAZARD!

This Metal Shears can quickly start up when handling while connected to an

air supply causing serious personal injury. Always disconnect the tool from the

air supply before changing Cutting Blades or performing maintenance.

FIG. 1