3

Form C-1206

TO REPLACE EMERY WHEELS

BBS32

1. Remove left hand cap – 2 screws (300C8-2)

– lift out emery wheel with bushing.

2. Remove screw (20C13-30).

3. Coat new emery wheel spindle with oil and

re-assemble to arm (620C1-21).

4. Repeat above steps for right hand emery wheel.

NOTE

Left and Right caps must be replaced in the same man-

ner that they were removed.

BBB32

1. Remove cap (35C5-45) and lift out emery

wheel and bushing. Then remove screw

(304C10-3) from left hand emery wheel and

pull out emery wheel (541C1-10). Replace

wheels and re-assemble.

2. Adjust wheels as outlined for BBR.

BBS32

Remove sharpener (637C1-23) from machine and disas-

semble as shown in diagram page 5 – replace emery wheel

(541C1-22). Lubricate – re-assemble – re-install.

220 VOLT MACHINES

When using the 220 volt machine on three phase outlets,

use adaptor (509C1-54) by simply mounting this adaptor

on the (25C5-49) single phase attachment plug. The two

live leads of the (615C1-5) three phase attachment plug

can be utilized for the power this machine requires.

KNIFE GUARD ADJUSTMENT

Knife guards (25C4-144) and (25C4-106) should be regu-

lated in a manner that only allows the material to pass

through the material to be cut.

REPLACEMENT BLADES

CAUTION

Do not use sewing machine oil or detergent oil. It is entirely too

light for cutting machine lubrication. For best results use spe-

cially compounded Eastman Oil or at least a good grade SAE 30

motor oil. Do not oil base plate rollers.

Do not overload with grease as machine will run hot at gear assembly.

Remove knife and gear and remove excessive grease.

MAINTENANCE PROCEDURES

1. Keep rollers of the base plate free of lint. Motor should be

blown clear of lint and dust weekly using air hose at 90

P.S.I.

2. Periodically check terminal pins on the terminal block and

the terminal in the attachment plug to insure full contact.

3. When replacing the knife on your cutting unit be sure to

clean out any lint build up between knife and standard.

4. If the cutting unit seems to lag or run hot when not cut-

ting, run machine with knife removed to check for over-

greasing or any obstructions.

5. When changing knife or cleaning machine check all screws

and nuts for tightness.

6. Carefully remove spring loaded brushes – replace brushes

when worn to less than .165 inches (4.2mm) or if springs

are less than .350 inches (9.00mm).

7. When your machine performance does not appear to be

up to par, contact your Eastman Machine authorized

dealer.

MOTOR BRUSH REPLACEMENT

When replacing brushes (36C1-13) in the motor, carefully remove the

(54C4-43) brush caps, remove the (34C1-58) brush with springs and re-

place brushes accordingly.

KNIFE SHARPENING

BBB32R – BBS32 – Connect power cord and switch motor on. To

obtain a fine, keen edge on the blade, press lightly on sharpener lever

or button with a constant pressure.

KNIFE SHARPENER REPLACEMENT

BBB32 – BBS32

CAUTION

Disconnect from electric power source when servicing.

As the emery wheels wear away and become farther apart, they must

be adjusted. Proceed as follows:

1. Slightly loosen four (4) slotted screws (300C8-2) holding

adjusting bushings in place.

2. With fingers, turn adjusting bushings (20C6-23) until em-

ery wheels are as close together as possible without touch-

ing and centered over knife. Both wheels should grind at

the same time when pressed lightly against knife with a

maximum 1/32 inch clearance between wheels. The sharp-

ened edge (bevel) should be no more than 1/16 inch.

3. Tighten four (4) screws.

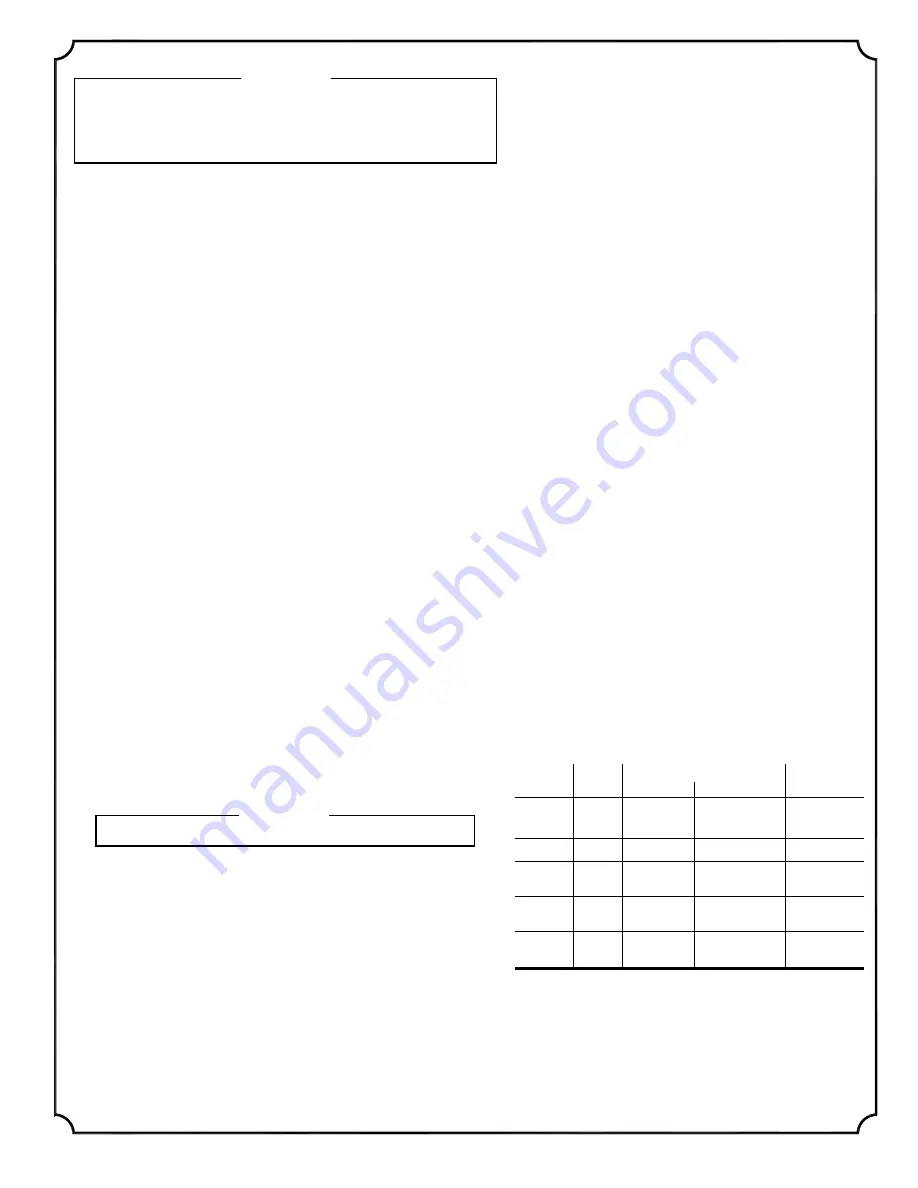

PLEASE SPECIFY MACHINE NAME AND SERIAL NUMBER WHEN ORDERING PARTS.

Machine

Part Number

Blade

Type

Size

Carbon

High Speed

Type

BBS32

2 1/2"

80C1-114

80C1-114HS

Round

80C1-138

*

—

Hex

BBB32

3 1/4"

80C1-84

*

80C1-84HS

Round

D2

2 1/4"

—

80C1-147HS

*

Round

D2H

80C1-149HS

Hex

BUZZ

2-1/32"

—

80C1-123HS

*

Semi Square

80C1-133HS

Octagon

*Standard Blade

Содержание BBS32

Страница 5: ...5 Form C 1206 ...

Страница 7: ...7 Form C 1206 TYPE BBB32 ...

Страница 9: ...9 Form C 1206 779 WASHINGTON STREET BUFFALO NEW YORK 14203 ...