Operation 17

M.D. Thermo

— Temperature controller for the L-Sealer heat element that is aligned

with the Machine Direction (M.D.). More specific information about setting the M.D.

temperature controller is provided in the pages following explanation of use of the

Operator’s Panel.

Start

— Green light indicates the machine is powered on and ready for operation or

operating. Press to start automatic operation once operating parameters have been

defined using the Operator’s Panel.

Stop

— Press the Red button to stop automatic sealing in a normal non-emergency

situation. The Red Stop button illuminates red indicates automatic sealing has been

stopped.

E-Stop Button

— In the event of an emergency, press in the large red mushroom

shaped E-Stop button. This brings the system to a halt in a way to avoid damage or

excessive film waste. In addition to the E-Stop on the Control Panel, there is also an E-

Stop at the outer corner of the machine at the Infeed end of the machine. To return the

machine back to normal operation, turn the activated E-Stop button so both E-Stops are

out, and then press the green Start button.

Main Power Switch

— Use to turn main power to the automatic L-sealer on or off.

CAUTION!

When the power is turned on be aware of sealer hot surfaces

and moving belts and rollers.

Other Features

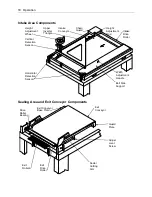

Film Unwinder

— The film unwinder is located behind the product infeed conveyor and

film separator/inverter area, behind and to the right of the L-sealer enclosure.

Pin Perforator

— The pin perforator is inside the film unwinder. The Pin Perforator is

synchronized with the film during normal operation. It creates holes in the film (To allow

air to escape during shrinking). The lever on the outside of the Film Unwind at the rear

of the infeed end is the Perforator Release Lever.

Perforator Release Lever

— The Perforator Release Lever allows the perforator to be

disengaged temporarily when necessary to allow the film to be threaded.

Infeed Conveyor

— The infeed conveyor is used to facilitate insertion of the product

between the bottom and top layers of film and transport the product into the seal area.

Width and Height Adjustment

— The infeed conveyor is adjustable for width to

achieve proper placement of the total width of the package, thereby allowing the product

to be placed precisely in the seal area and film each time. Infeed film height adjustment

allows the height of the upper film inverter triangle to be changed for differing heights of

product.

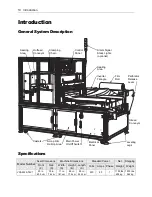

Содержание Value VSA2530TK-V1

Страница 1: ...VSA Value Series Auto L Sealers User Guide VSA2530TK V1 ...

Страница 2: ......

Страница 4: ......

Страница 72: ...72 Appendix A Electrical Schematic Appendix A Electrical Schematics Electrical Schematics VSA2530 TKV1 ...

Страница 73: ...Appendix A Electrical Schematic 73 VSA2530 TKV1 Sheet 2 of 5 ...

Страница 74: ...74 Appendix A Electrical Schematic VSA2530 TKV1 Sheet 3 of 5 ...

Страница 75: ...Appendix A Electrical Schematic 75 VSA2530 TKV1 Sheet 4 of 5 ...

Страница 76: ...76 Appendix A Electrical Schematic VSA2530 TKV1 Sheet 5 of 5 ...

Страница 77: ...Appendix A Electrical Schematic 77 Electrical Schematics VSA2530 TKV2 VSA2530 TKV2 Sheet 1 of 6 ...

Страница 78: ...78 Appendix A Electrical Schematic VSA2530 TKV2 Sheet 2 of 6 ...

Страница 79: ...Appendix A Electrical Schematic 79 VSA2530 TKV2 Sheet 3 of 6 ...

Страница 80: ...80 Appendix A Electrical Schematic VSA2530 TKV2 Sheet 4 of 6 ...

Страница 81: ...Appendix A Electrical Schematic 81 VSA2530 TKV2 Sheet 5 of 6 ...

Страница 82: ...82 Appendix A Electrical Schematic VSA2530 TKV2 Sheet 6 of 6 ...

Страница 83: ...Appendix B Air Diagram Pneumatic Schematic 83 Appendix B Air Diagram Pneumatic Schematic ...

Страница 88: ......