14 Installation and Setup

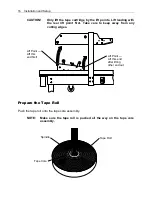

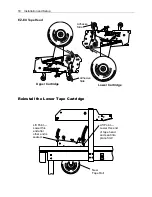

Set Machine Height

To adjust the leg height, loosen the screws shown on each leg. Slide the insert up or

down to the required height, and then refasten the screws.

Location Requirements

To move the SB-2 HD to the desired location. you will need to use a pallet jack or fork

lift. If you have purchased the optional locking casters you can move the taper easily

over a smooth flat surface.

When installing the SB-2 HD Taping System please be aware of the following

considerations:

1. The mounting surface is flat and level.

2. Conveyor or packing table height.

3. Alignment with packaging line.

When the SB-2 HD Taper is installed in the operating location you will need access to:

1. The power switch.

2. Height and width adjustments.

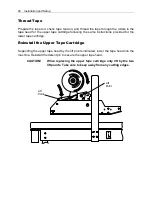

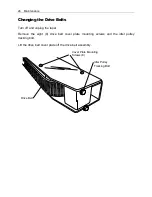

3. Tape loading (Both upper and lower tape cartridges).

A packing table may be provided at the in-feed end where the packer can fill boxes and

close the flaps prior to feeding the boxes into the machine. It may also be convenient to

place a separate table, bin, or exit conveyor near the exit end of the taper for handling

of sealed cases.

It is essential that the table and conveyor be at the machine bed height.

The machine should be placed on a flat, level floor so that it does not rock or move.

Optional locking casters are available to provide portability; however, we recommend

that the machine be securely locked in place when used.

Screw

Screw

Содержание SB-2 HD

Страница 1: ...SB 2 HD Side Belt Heavy Duty Industrial Case Taping System User Guide ...

Страница 2: ......

Страница 4: ......

Страница 6: ......

Страница 44: ......