Page 8

MODEL W2265 ONLY

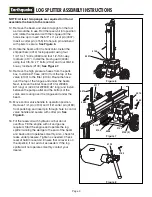

8. Remove the 90 degree street elbow (4122) and the

1” barbed coupler (4160) and insert the street

elbow first into the suction screen (4307) that has

already been assembled into the reservoir. Tighten

the elbow until it faces to the right or engine side of

the log splitter when looking at the log splitter from

the front. Then insert the 1” barbed coupler into the

street elbow and tighten.

See Figure 4.

9. Assemble the pre-assembled engine assembly onto

the reservoir as shown using four 3/8-16 x 1” bolts

(2102) and four 3/8-16 bi-way locknuts (2104).

Attach the suction hose (4327) between the 1”

barbed coupler and the hydraulic pump (4344)

using two hose clamps (4169).

See Figure 4.

Go to

Step 12.

MODEL W2808 ONLY

10. Remove the 1” barbed coupler (4160) from the

parts bag and assemble into the suction screen

(4307) that has been installed at the factory.

Tighten.

See Figure 5.

11. Assemble the engine plate (4371) onto the reservoir

using four 3/8-16 x 1” bolts (2102) and four 3/8-16

bi-way locknuts (2104). Next, assemble the engine

assembly to the plate using four 5/16-18 x 1-1/2”

(48156) and four 5/18-18 bi-way locknuts (60G56).

Attach the suction hose (4372) using two hose

clamps (4169) between the 1” barbed coupler and

the hydraulic pump (4323).

See Figure 5.

LOG SPLITTER ASSEMBLY INSTRUCTIONS

Figure 4

Figure 5

4122

4160

4327

2102

2104

4307

4169

2102

4344

48156

4323

60G56

2102

4371

4372

4169

4169

4160

4307

2104 (4)