DYNABRADE

®

DYNABRADE, INC.,

8989 Sheridan Drive

•

Clarence, NY 14031-1490

•

Phone: (716) 631-0100

•

Fax: 716-631-2073

•

International Fax: 716-631-2524

DYNABRADE EUROPE S.àr.l.,

Zone Artisanale

•

L-5485 Wormeldange—Haut, Luxembourg

•

Telephone: 352 76 84 94 1

•

Fax: 352 76 84 95 1

© DYNABRADE, INC., 2004

PRINTED IN USA

PD04.06_Rev.2_04/05

Visit Our Web Site:

www.dynabrade.com

Email:

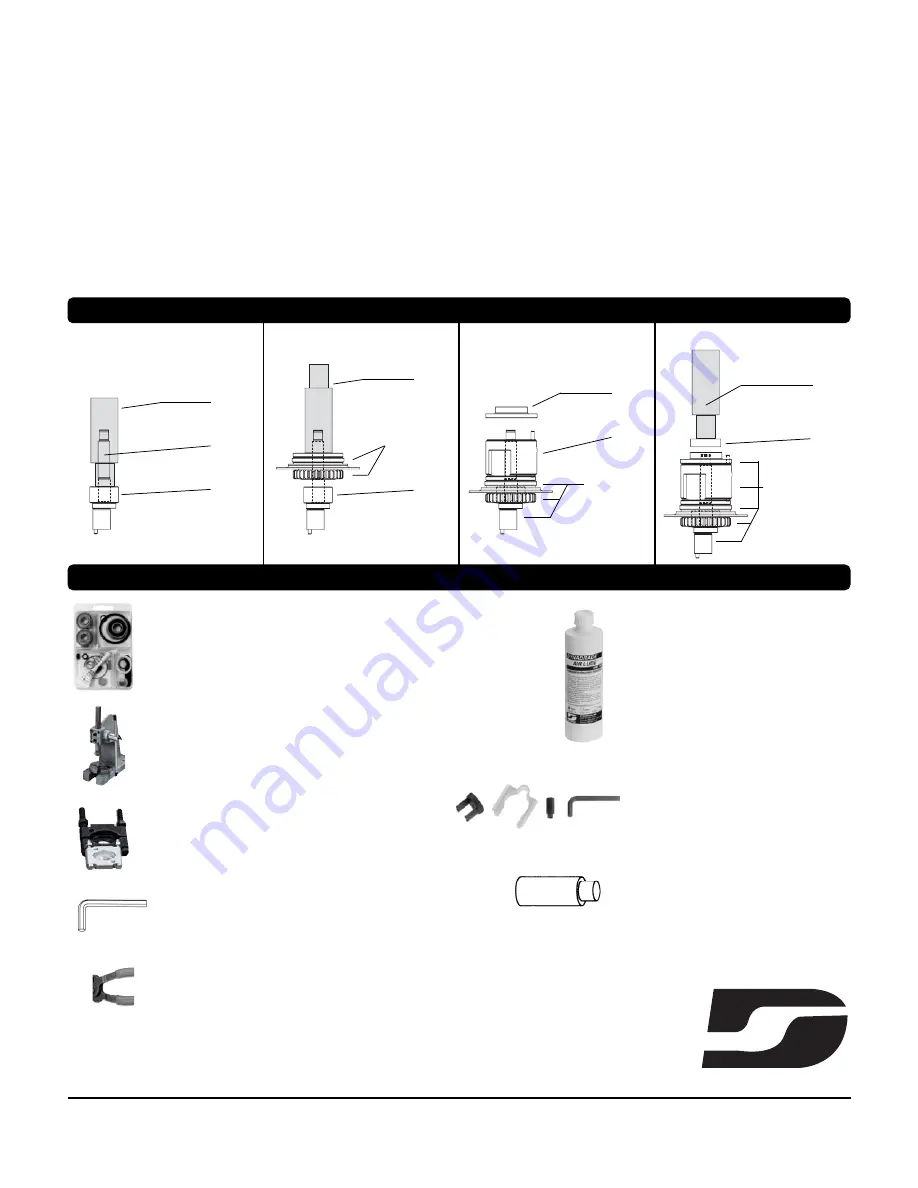

98221 Motor Tune-Up Kit

•

Includes assorted parts to

help maintain and repair motor.

96232 (#2) Arbor Press

•

This arbor press is ideal for the disassembly

and assembly of air motors.

96346 2" Bearing Separator

•

Use the separator to remove gears

and bearings.

Dynabrade Air Lube

•

Formulated for pneumatic equipment.

•

Absorbs up to 10% of its weight in water.

•

Prevents rust and formation of sludge.

•

Keeps pneumatic tools operating longer

with greater power and less down time.

95842:

1pt. (473 ml)

95843:

1gal. (3.8 L)

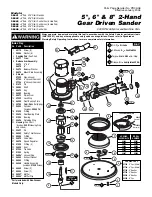

Diagrams

Optional Accessories

3.

Install the

98459

O-Ring onto the

56579

Valve Stem, apply a small amount of petroleum lubricant to the o-ring and insert the shortest portion (from the end to the o-ring) of

the valve stem assembly into the speed regulator.

4.

Install the

56582

Safety Throttle Lever onto the housing and secure it in place with the

95627

Pin.

5.

Install the

56598

Seal into the air inlet passage of the housing.

6.

Install the

56586

Vacuum Plug into the exhaust passage of the housing. (See Exploded View)

7.

Use needle-nose pliers to grasp and install the

51944

Tip Valve so that it fits under the

56579

Valve Stem.

8.

Install the large end of the

51943

Spring into the air inlet passage of the handle.

9.

Install the

56469

Gasket onto the mounting surface of the handle.

10.

Install the

96459

O-Ring onto outside diameter of the air inlet passage at the location of the first shoulder and apply a small amount of petroleum lubricant to the o-ring.

11.

Connect the handle to the housing and secure it in place with the four screws. Note: The two longer screws, Part Number

96454

(2) secure the

56581

Grip to the housing.

12.

Install the

56597

Muffler and secure it in place with the

56596

Muffler Clip. (See Exploded View)

Handle and Valve Assembly Complete. Tool Assembly Complete. Please allow 30 minutes for adhesives to cure before operating tool.

Important:

Motor should now be tested for proper operation at 90 PSIG. If motor does not operate properly or operates at a higher RPM than marked on the tool, the tool should

be serviced to correct the cause before use. Before operating, place 2-3 drops of Dynabrade Air Lube (P/N

95842

) directly into air inlet with throttle lever depressed. Operate tool

for 30 seconds to determine if tool is operating properly and to allow lubricating oils to properly penetrate motor.

Loctite

®

is a registered trademark of Loctite Corp.

Drawing 1

Drawing 2

02695

Bearing

Drawing 3

Drawing 4

57091

Bearing Press Tool

57091

Bearing Press Tool

57091

Bearing Press Tool

01206

Bearing

Cylinder w/Front

Bearing Plate,

Lock Ring,

Pinion Gear

and Shaft

56595

Cylinder

54629

Rear Bearing Plate

Lock Ring and

Pinion Gear

Lock Ring,

Pinion Gear

and Shaft

56052

Bearing

96283 Motor Repair Kit:

•

Contains special tools for

disassembly/assembly of machine.

56589

Shaft

56052

Bearing

96213 Bearing Removal Tool

•

This tool is used to pass through the I.D.

of the bearing plate and to push against

the I.D. of the bearing.

96343 Retaining Ring Pliers

•

Internal/external retaining ring pliers.

Tip diameter - 0.038" (0.96mm)

95134

– 9/64" Hex Wrench

95135

– 5/32" Hex Wrench