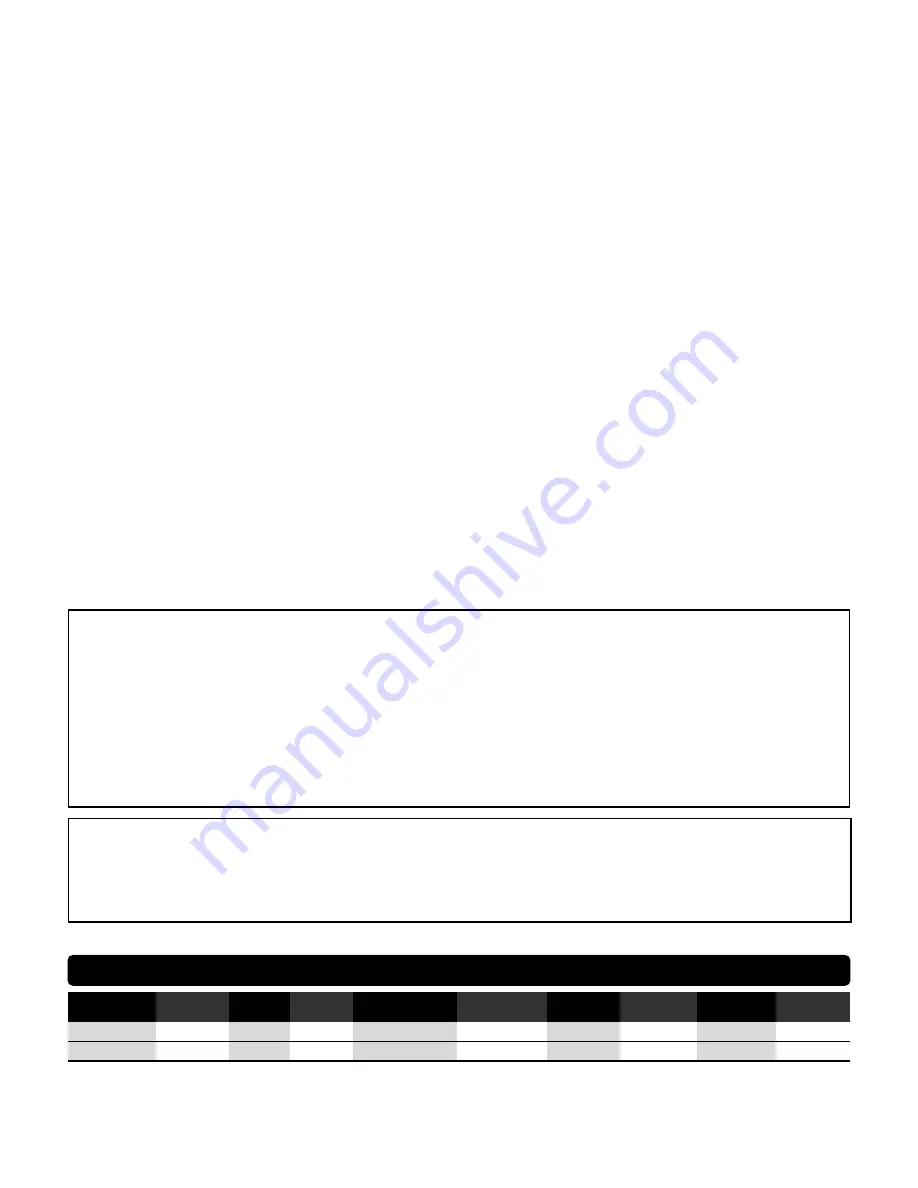

Machine Specifications

6

Model

Motor

Motor

Sound

Maximum Air Flow

Collet Insert

Air Pressure

Weight

Length

Height

Number

hp (W)

RPM

Level

SCFM (LPM)

Size

PSIG (Bars)

Pound (kg)

Inch (mm)

Inch (mm)

56723

.4 (298)

25,000

77 dB(A)

24 (680)

1/4" & 6 mm

90 (6.2)

1.6 (.7)

9.7 (247)

5.9 (150)

56727

.4 (298)

5,000

80 dB(A)

25 (708)

1/4" & 6 mm

90 (6.2)

2.3 (1.0)

10 (254)

8.3 (212)

Additional Specifications: Air Inlet Thread 1/4" NPT • Hose Size 1/4" or 6 mm

Sound Level is the pressure measurement according to the method outlined in ISO regulation ISO-15744.

Lifetime Warranty

All Dynabrade portable pneumatic power tools are rigorously inspected and performance tested in our factory before shipping to our customers. If a

Dynabrade tool develops a performance problem and an inherent defect is found during normal use and service, Dynabrade will warrant this tool

against defects in workmanship and materials for the lifetime of the tool. Upon examination and review at our factory, Dynabrade shall confirm that

the tool qualifies for warranty status, and will repair or replace the tool at no charge to the customer. Normally wearable parts and products are NOT

covered under this warranty. Uncovered items include bearings, contact wheels, rotor blades, regulators, valve stems, levers, shrouds, guards, O-

rings, seals, gaskets and other wearable parts. Dynabrade’s warranty policy is contingent upon proper use of our tools in accordance with factory

recommendations, instructions and safety practices. It shall not apply to equipment that has been subjected to misuse, negligence, accident or

tampering in any way so as to affect its normal performance. To activate lifetime warranty, customer must register each tool at www.dynabrade.com.

Dynabrade will not honor lifetime warranty on unregistered tools. A one-year warranty will be honored on all unregistered portable pneumatic power

tools. Lifetime warranty applies only to portable pneumatic tools manufactured by Dynabrade, Inc. in the USA. Lifetime warranty applies only to the

original tool owner; warranty is non-transferable.

Notice

All Dynabrade motors use the highest quality parts and metals available and are machined to exacting tolerances. The failure of quality pneumatic

motors can most often be traced to an unclean air supply or the lack of lubrication. Air pressure easily forces dirt or water contained in the air supply into

motor bearings causing early failure. It often scores the cylinder walls and the rotor blades resulting in limited efficiency and power. Our warranty obligation

is contingent upon proper use of our tools and cannot apply to equipment which has been subjected to misuse such as unclean air, wet air or a lack of

lubrication during the use of this tool.

3. Model 56723:

Install the

02649

Bearing into the front bearing plate and install these onto the rotor.

4.

Install the

01435

Collet Body onto the

01475

Rotor. (Torque to 17 N•m/150 in. lbs.)

5. Model 56727:

Position the

54553

Rotor with the

01479

Spacer in the arbor press with the pinion gear pointing up.

6.

Use the raised center of the

96240

Bearing Press Tool and arbor press to install the

02649

Bearing, shims and

01478

Front Bearing Plate.

7.

Use a .001" (0.3 mm) thick feeler gauge to check the clearance between the bearing plate and the face of the rotor.

8.

Clearance should be .001"-.0015" (0.3-0.4 mm). Note: If the clearance needs adjustment, repeat steps 2-6. Add or remove shims as required.

9.

Lubricate the

01480

Vanes with the

95842

Dynabrade Air Lube 10W/NR (or equivalent). Install vanes into the rotor.

10.

Install the

01476

Cylinder so that the air inlet opening will align with the air inlet opening in the

02673

Rear Bearing Plate.

11.

Use the RAISED OUTSIDE DIAMETER of the

96242

Bearing Press Tool and the arbor press to install the

02696

Bearing into the

02696

Rear Bearing Plate.

12.

Use the RAISED CENTER of the

96242

Bearing Press Tool and the arbor press to install the bearing/plate onto the rotor.

13.

Carefully press the bearing/plate down until it just touches the cylinder. This will establish a snug fit between the bearing plates and the cylinder.

14.

Apply a small amount of white grease to the seal of the

02696

Bearing, and stick the

02679

Shield against the bearing. Carefully slide the motor assembly

into the housing.

15. Model 56723:

Install the

01580

Felt Silencer onto the front of the air motor.

16. Model 56727:

Install the flat side of the

50778

Spacer against the

02649

Bearing. Install the planetary gear assembly into the

50776

Housing, aligning the

lubricant and set screw access holes with the notched openings in the ring gear. Apply a small amount of Loctite #567 (or equivalent) to the threads of the

50784

Set Screw and install with a 5/64" hex key.

17.

Apply a small amount of Loctite #567 (or equivalent) to the threads of the rear exhaust cover and install it onto the housing. (Torque to 28 N•m/250 in. lbs.)

18. Model 56727:

Install the

50011

Collet Body.

19.

Install the shroud and secure it with the clamp.

Motor Assembly Complete.

Throttle Positioning Procedure:

IMPORTANT: Perform this procedure carefully. Do not entirely separate the 01546 or 50776 Housing from the valve housing. Loosen the 01461 Lock Nut

only enough to make the throttle lever adjustment.

1.

Place the

52296

Repair Collar around the valve housing and secure it in a vise so that the

01546

or

50776

Housing is pointing up.

2.

Slip the

01558

Collar down onto the valve housing to expose the

01461

Lock Nut.

3.

With a firm hold on the

01546

or

50776

Housing, use a 34 mm or an adjustable wrench to turn the lock nut clockwise to loosen the

01546

or

50776

Housing

from the valve housing.

4.

Place the throttle lever in the desired position.

Note:

Allow for additional rotation of the

01546

or

50776

Housing as the

01461

Lock Nut is tightened.

5.

Grasp the

01546

or

50776

Housing firmly to limit rotation. Use a 34 mm or an adjustable wrench to tighten the

01461

Lock Nut. (Torque to 45 N•m/400 in. lbs.)

6.

Slip the

01558

Collar back over the

01461

Lock Nut.

Throttle Positioning Procedure Complete. Tool Assembly Complete.

Important:

Motor should now be tested for proper operation at 90 PSIG. If motor does not operate properly or operates at a higher RPM than marked on the

tool, the tool should be serviced to correct the cause before use. Before operating, place 2-3 drops of Dynabrade Air Lube (P/N

95842

) directly into air inlet

with throttle lever depressed. Operate tool for 30 seconds to determine if tool is operating properly and to allow lubricating oils to properly penetrate motor.

Loctite

®

is a registered trademark of Loctite Corp.