33

Dymax SG-200 High-Flow Spray Gun System User Guide

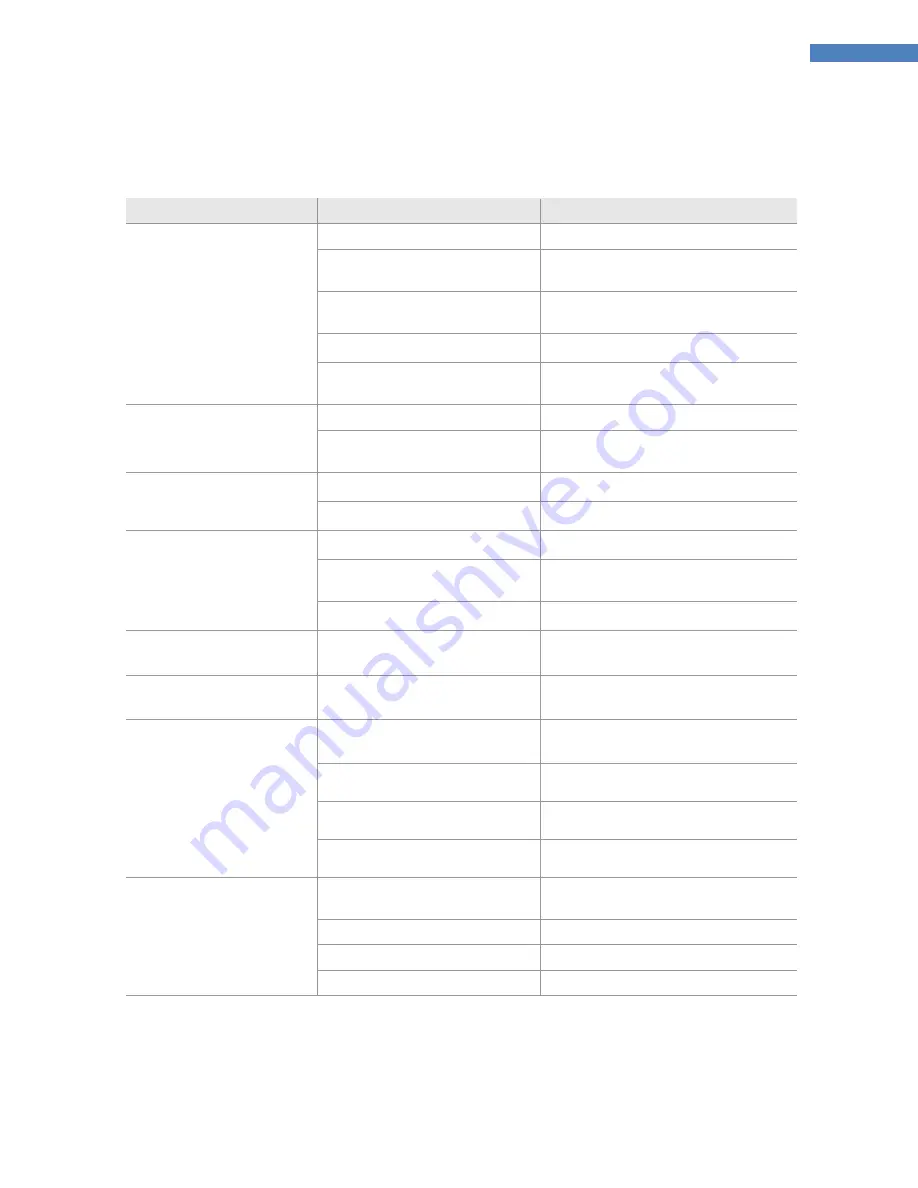

Troubleshooting

Table 2. Troubleshooting for the SG-200 Spray Gun

Problem

Possible Cause

Corrective Action

Spray valve does not cycle

Air pressure to air section too low

Increase air pressure to 60-100 psi

Packing nut is too tight

Loosen packing nut until valve just begins

to cycle, retighten

Stroke adjuster is bottomed out

Back out stroke adjuster by turning it

counter-clockwise

Material is cured in the valve

Disassemble and clean valve

Valve was assembled without

lubricating the o-ring seals

Disassemble valve, lubricate seals,

and re-assemble

Material leaks from valve tip

Needle and/or seat are worn

Replace parts as necessary

Seat is not tightened enough against

fluid section

Use seat wrench to tighten seat onto fluid

section

Valve leaks from mid-section

Packing nut is loose

Tighten packing nut until snug

Packing is worn

Replace packing

Valve does not spray anything

Fluid pressure is too low

Increase fluid pressure

Atomization pressure too high

impeding material flow

Reduce atomizing pressure, increase nozzle

size

Material cured in fluid section

Disassemble valve and clean

Spray rate too fast

Material PSI too high

Reduce material pressure

Spray rate too slow

Material PSI/flow rate too low

Increase material pressure. Increase nozzle

size

Air bubbles in fluid

Valve not properly purged

Flip valve upside down and cycle until air

bubbles are removed

Problem with fluid delivery system

Diagnose and repair

Not enough material flow

Nozzle bore too small

Atomizing air pressure set too high

Reduce atomizing air pressure

Poor spray pattern

Cured material at tip of needle and

seat

Remove air cap and clean tip

Cured material in air cap

Remove air cap and clean

Incorrect atomizing air pressure

Adjust atomizing air pressure

Damaged needle and or seat

Replace parts as necessary