sYMptoM

possible cause(s)

corrective action

Safety hook spreads

1. Point loading of hook

1. Replace hook

2. Load exceeds rated capacity of unit

2. Lighten load, reduce %

of incline or reduce load friction

Cable breaks

1. Cable damage due to miswrap.

1. Keep tension on cable at all times

2. overloading

2. Reduce load

Cable miswrap

Loose cable being wound onto drum

Keep tension on cable at all times

and/or crushing

Load creeps when power is oFF

1. Brake/clutch out of adjustment

1. adjust (see Maintenance).

2. Roller clutch, not engaging

2. Replace.

3. overloading

3. Reduce load.

4. Brake slipping

4. Replace

Winch motor runs but fails

1. Clutch is slipping.

1. Check clutch lining for grease or oil. See

to wind cable

“Maintenance” for clutch adjustment procedure.

2. Gear train is damaged.

2. Check and Repair

Winch motor runs hot

In operation too long

Let motor cool for at least 20 minutes. (See Winch

Rating Section.)

Winch motor fails to run

Electrical

Check the following: power supply, wiring, control

switch, male/female connections and motor.

Cable will not pull out (free wheel)

1. Sticking cable

1. avoid cable miswrap.

2. Sticking clutch

2.a. “Jog” power switch with clutch in free wheel

(No load only).

b. disassemble, clean & readjust clutch, see

“Maintenance”.

Smokes

Normal on initial power down use

None

troubleshooting chart

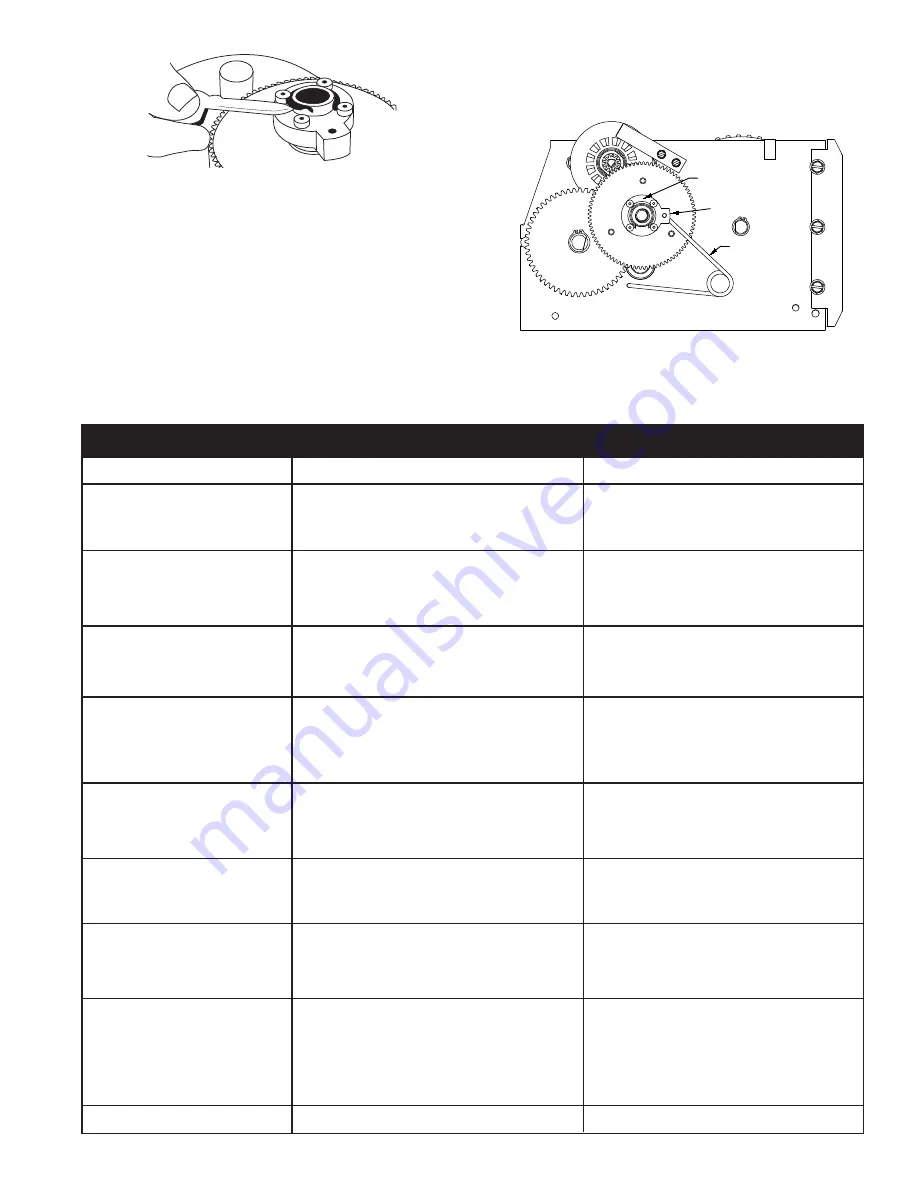

tighten the clutch mechanism) the spring lug on

the spring keeper should come to rest at

approximately the 3:00 o’clock position.(See

FIG. 7)

5. Check the pulley block and hook assembly

(ModELS Sa7000aC aNd Sa12000aC) to be

sure that the pulley rotates freely on the bronze

pulley spacer. occasional greasing of these two

items is recommended.

FIG. 6

FIG. 7

o-ring illustration

clutch spring illustration

5

Clutch Spring

Keeper

Spring Lug

Clutch Spring