6.2

Checks

1. Perform the following checks during oper-

ation:

Check air connection for correct seat

and leaks.

Check air car for cleanliness.

Check nozzle for cleanliness.

6.3

Selecting air cap

You can convert the spray gun from a con-

ventional spray gun to a LVLP spray gun by

swapping the air cap.

Conventional air cap (CF)

The conventional air cap is used for decora-

tive surfaces and an application with more

focus on the atomization.

Conventional air cap features:

Mist arm

Fine atomization

Transfer rate > 65 %

Average air consumption 240 l/min

Air cap LVLP (LF)

The air cap LVLP is used for applications

requiring a good transfer rate and spray pat-

tern.

Air cap LVLP

Mist arm

Transfer rate > 75 %

Average air consumption 300 l/min

6.4

Changing the air cap

Personnel:

Operator

+ additional qualification explosion pro-

tection

Protective equipment:

Protective workwear

Protective gloves

Removing the air cap

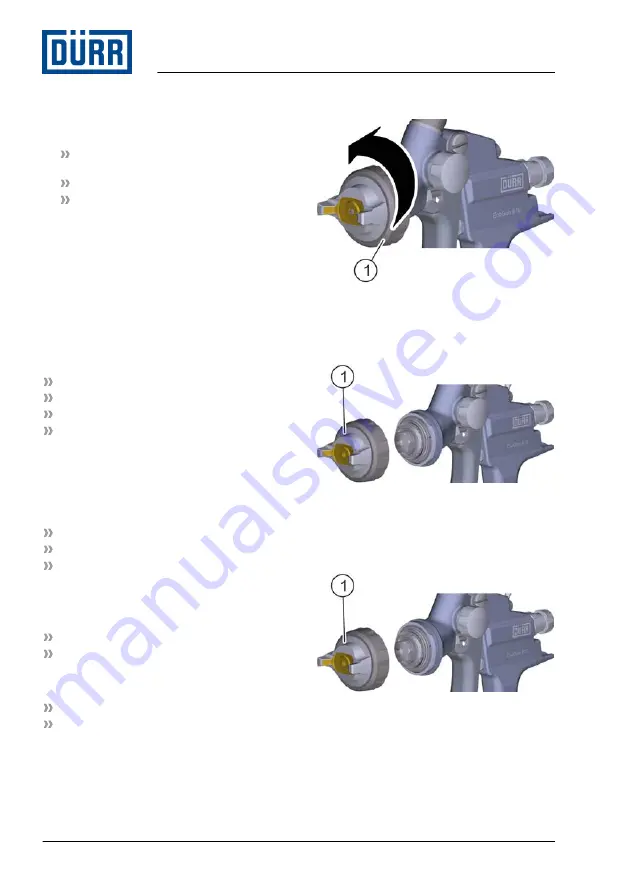

Fig. 7: Loosen cap nut.

1. Loosen the cap nut (1) by a ¼ turn coun-

terclockwise.

Fig. 8: Removing the air cap

2. Remove the air cap (1).

Assembling the air cap

Fig. 9: Placing the air cap

3. Place the air cap (1).

Operation

05/2018

EcoGun 910 - MSG00003EN

10/32