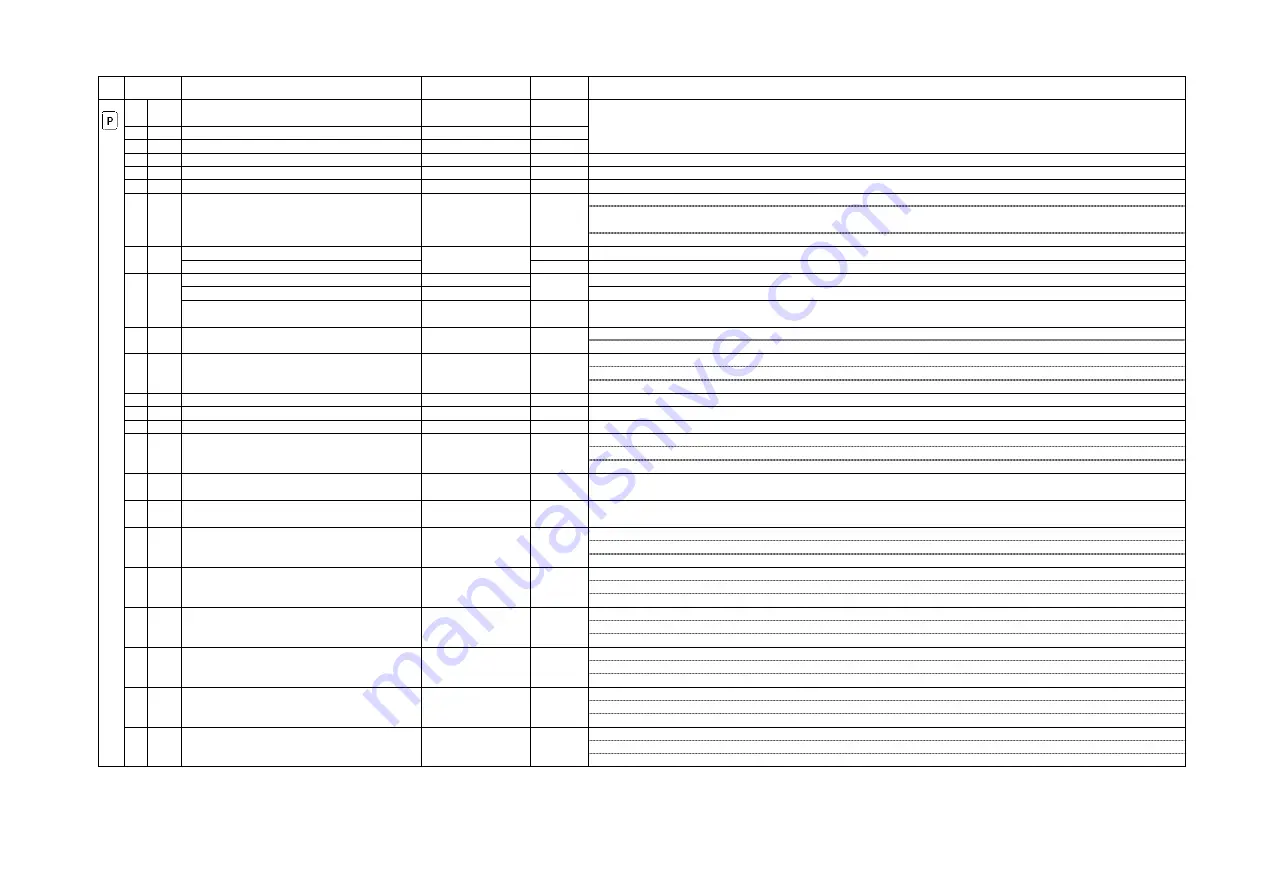

PAGE - 6

Key

Parameters Function

Range

Pre.setting

Description

HVP -20 Parameters List for DA-251 (MAC. 35)

Parameters

Code

89

D1

Delayed timing prior to upper trimmer engaged

at down-stop

0 - 990 ms

30

90

D2

Setting timing of upper trimming at down-stop

0 - 2500 ms

90

91

D3

Timing recall of upper trimming at down-stop

0 - 990 ms

120

92

W1

Delayed timing prior to wiper engaged

0 - 980 ms

0

Time setting between needle up to wiper active.

93

W2

Setting timing of wiping

0 - 9990 ms

40

Wiper ON timer setting.

94

WF

Delayed timing prior to foot lifter engaged

0 - 990 ms

50

Timer setting between wiper OFF to presses foot ON.

Condense-Stitch function by

【

027. CT

】

timer for needle up & motor stop.

ON

:

Enable. Note :

【

021. EBT

】

=ON,

【

022. EBC

】

=8,

【

023.EBD

】

=3 and

【

024.EBN

】

=2 and

【

027. CT

】

=100

must be adjusted.

OFF

:

Disable.

WEDA cutter delay stitch count

10

WEDA cutter delay stitch count setting.

Setting stitches of Condense-Stitch sewing

8

Valid only when the [095. CSF] = ON.

Tape cutter on timer

0 - 2500 ms

Tape cutter on timer setting x10 = 100 ms.

Bobbin counter alarm preaction value

0 - 250 stitches

When

【

042.CUD

】

= US,DS the value is bobbin counter alarm preaction value.

Setting stitches prior to stop beyong Condense-

Stitch

0 - 250 stitches

0

Valid only when the [095. CSF] = ON.

ON

:

Normal stitch length.

OFF

:

Long stitch length.

Edge sensor function selection..

ON

:

Enable.

OFF

:

Disable.

100

SRS Edge sensor signal check 1

0 - 99 stitches

1

Only valid when

【

099. SEN

】

set at ON. To avoid photo interference.

101

CMS Edge sensor signal check 2

0 - 99 stitches

3

Only valid when

【

099. SEN

】

set at ON. To avoid photo interference.

102

SE

Setting stitches from edge sensing to stop

1 - 999 stitches

6

Setting Stitches to stop., when edge signal detected. Only valid when

【

099. SEN

】

set at ON

When edge signal detected out. Motor will do the trimming cycle automatically.

ON : After the stitches of

【

102. SE

】

finished, trimming works.

OFF : After the stitches of

【

102. SE

】

finished, trimming doesn't work.

104

PSU Stitches for emergency up-stop

1 - 99 stitches

6

When

【

PSU

】

signal detected, running the stitches then stop at UP position.

The speed of setting stitches is set by

【

009. A

】

.

105

PSD Stitches for emergency down-stop

1 - 99 stitches

6

When

【

PSD

】

signal detected, running the stitches then stop at DOWN position.

The speed of setting stitches is set by

【

009. A

】

.

When the pedal on and the edge signal detected, the motor can start running.

ON

:

Enable.

OFF

:

Disable.

When motor running, manually push the Touch Back switch , reverse solenoid engaged on at needle up.

ON

:

Valid.

OFF

:

Invalid.

When motor running, manually push the Touch Back switch , reverse solenoid engaged on at needle down.

ON

:

Valid.

OFF

:

Invalid.

During sewing, reverse output will be OFF at needle UP or DOWN position .

ON

:

At

『

needle UP

』

position.

OFF

:

At

『

needle DOWN

』

position.

The trimming and reverse solenoid activated on the same time.

ON

:

Valid.

OFF

:

Invalid.

Correction mode selection for Touch-Back Switch. Note :

【

010. ACD

】

= OFF and

【

011. RVM

】

= B

1: Doing correction with one touch the Touch-Back switch .

2: Doing correction with double touch the Touch-Back switch.

P

O

W

E

R

..

O

N

0 - 99 stitches

97

TK3

Only valid when

【

078. TRM

】

set at

『

KB

』

mode.

Signal output from the wiper MW.

See the KB timing chart.

ON/OFF

OFF

95

CSF

Condense-Stitch function selection

ON/OFF

ON/OFF

OFF

10

96

ON/OFF

OFF

103

SET

Trimming mode at sensory stop

ON/OFF

OFF

99

SEN Edge sensor function selection

ON/OFF

ON

107

S7U

Manual Back-Tacking engaged at

needle-up position

ON/OFF

OFF

106

PSN Re-start function at emergency stop

ON/OFF

ON

109

ROF Mode for de-engaging Back-Tacking

ON/OFF

OFF

108

S7D

Manual Back-Tacking engaged at

needle-down position

OFF

111

COR Correction Mode of Touch-Back Switch

1/2

2

110

TB

Mode for Back-Tacking at trimming cycle

98

SLU

WN3

Stitch length selection for backtack

+

From

the

library

of:

Diamond

Needle

Corp