Machine head

Service Instructions 745-35-10 S/745-35-10 A - 02.0 - 04/2017

29

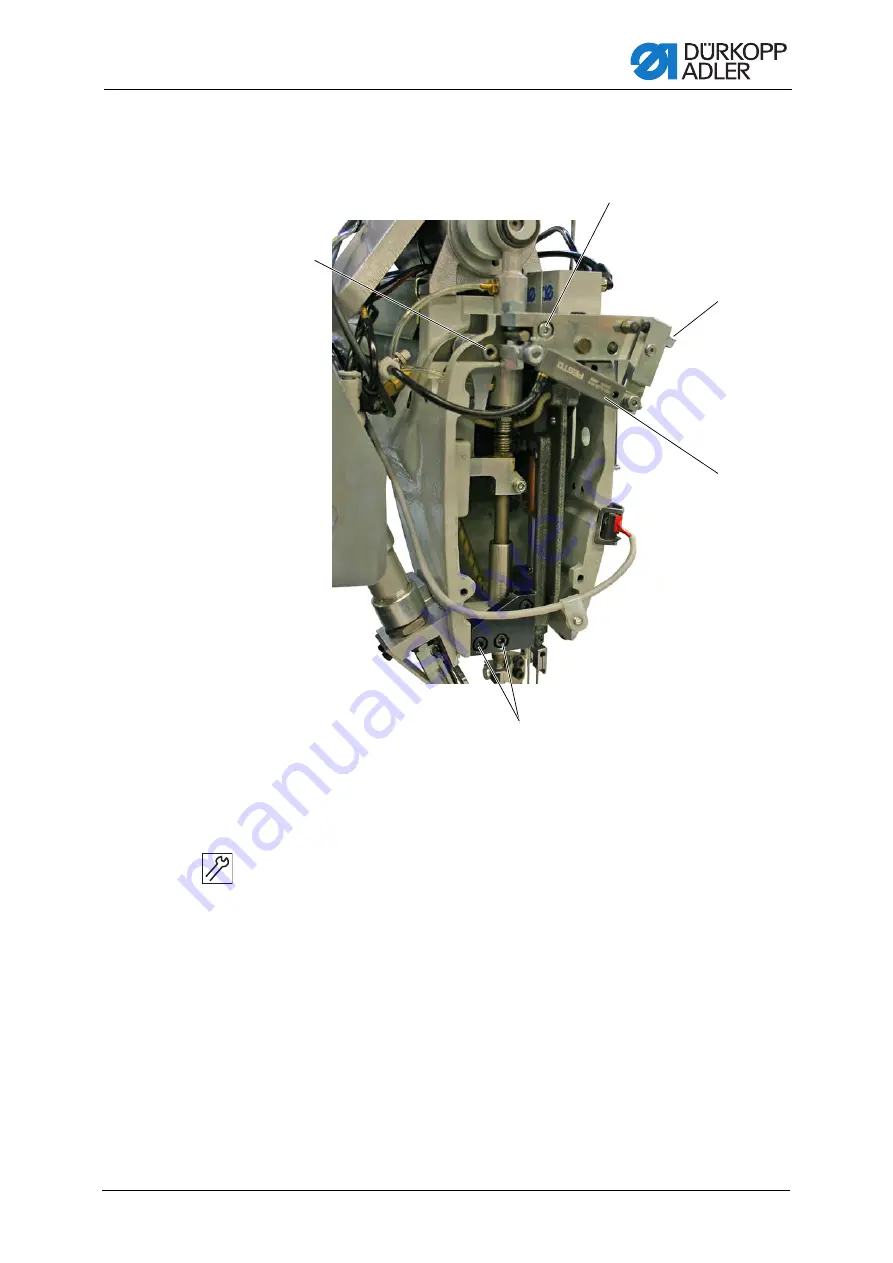

Disassembling the needle bar linkage

Fig. 17: Disassembling the needle bar linkage (1)

To remove the needle bar linkage:

1.

Loosen screws (4) and (7).

2.

Remove the thread advancing device (6).

3.

Loosen the screw (5).

4.

Loosen the screw (8).

(4)

- Screw

(5)

- Screws

(6)

- Thread advancing device

(7)

- Screw

(8)

- Screw

④

⑧

⑤

⑥

⑦

Содержание 745-35-10 A

Страница 1: ...745 35 10 S 745 35 10 A Service Instructions...

Страница 10: ...About these instructions 8 Service Instructions 745 35 10 S 745 35 10 A 02 0 04 2017...

Страница 13: ...Safety Service Instructions 745 35 10 S 745 35 10 A 02 0 04 2017 11...

Страница 16: ...Safety 14 Service Instructions 745 35 10 S 745 35 10 A 02 0 04 2017...

Страница 86: ...Transport carriage 84 Service Instructions 745 35 10 S 745 35 10 A 02 0 04 2017...

Страница 98: ...Transport clamps 96 Service Instructions 745 35 10 S 745 35 10 A 02 0 04 2017...

Страница 134: ...Aligning the machine head 132 Service Instructions 745 35 10 S 745 35 10 A 02 0 04 2017...

Страница 136: ...Setting fabric sliding plate and vacuum plate 134 Service Instructions 745 35 10 S 745 35 10 A 02 0 04 2017...

Страница 148: ...Folder 146 Service Instructions 745 35 10 S 745 35 10 A 02 0 04 2017...

Страница 156: ...Additional equipment 154 Service Instructions 745 35 10 S 745 35 10 A 02 0 04 2017...

Страница 312: ...Maintenance 310 Service Instructions 745 35 10 S 745 35 10 A 02 0 04 2017...

Страница 314: ...Decommissioning 312 Service Instructions 745 35 10 S 745 35 10 A 02 0 04 2017...

Страница 316: ...Disposal 314 Service Instructions 745 35 10 S 745 35 10 A 02 0 04 2017...

Страница 328: ...Troubleshooting 326 Service Instructions 745 35 10 S 745 35 10 A 02 0 04 2017...

Страница 365: ...Appendix Service Instructions 745 35 10 S 745 35 10 A 02 0 04 2017 363 22 3 Pneumatic diagram...

Страница 366: ...Appendix 364 Service Instructions 745 35 10 S 745 35 10 A 02 0 04 2017...

Страница 367: ...Appendix Service Instructions 745 35 10 S 745 35 10 A 02 0 04 2017 365...

Страница 368: ...Appendix 366 Service Instructions 745 35 10 S 745 35 10 A 02 0 04 2017...

Страница 369: ...Appendix Service Instructions 745 35 10 S 745 35 10 A 02 0 04 2017 367...

Страница 370: ...Appendix 368 Service Instructions 745 35 10 S 745 35 10 A 02 0 04 2017...

Страница 371: ...Appendix Service Instructions 745 35 10 S 745 35 10 A 02 0 04 2017 369...

Страница 372: ...Appendix 370 Service Instructions 745 35 10 S 745 35 10 A 02 0 04 2017...

Страница 373: ...Appendix Service Instructions 745 35 10 S 745 35 10 A 02 0 04 2017 371...

Страница 374: ...Appendix 372 Service Instructions 745 35 10 S 745 35 10 A 02 0 04 2017...

Страница 375: ...Appendix Service Instructions 745 35 10 S 745 35 10 A 02 0 04 2017 373...

Страница 376: ...Appendix 374 Service Instructions 745 35 10 S 745 35 10 A 02 0 04 2017...

Страница 377: ...Appendix Service Instructions 745 35 10 S 745 35 10 A 02 0 04 2017 375...

Страница 378: ...Appendix 376 Service Instructions 745 35 10 S 745 35 10 A 02 0 04 2017...

Страница 379: ...Appendix Service Instructions 745 35 10 S 745 35 10 A 02 0 04 2017 377...

Страница 380: ...Appendix 378 Service Instructions 745 35 10 S 745 35 10 A 02 0 04 2017 22 4 Pneumatic diagram throw over stacker...

Страница 381: ......