7

4

15

temperature set point. This is the temperature that the machine will reach and hold. The temperature

can be increased or decreased in 1° increments by pressing and releasing the up or down button.

To rapidly increase or decrease the temperature, press and hold the button. When the machine

reaches the set point temperature, the Ready light (green) will illuminate, and a two second beep

will sound. If a significant change in the set point temperature occurs, the Wait light (red) illuminates

until the laminator reaches the new set point temperature. At this time the Ready light will illuminate

again. Note: depending on room conditions and desired set point, it will take between 20 and 30

minutes for the ready indicator to come on.

Standard Presets (H)

The Laminator is equipped with 2 factory presets. The buttons are labeled 275 and 225. These

buttons will set both a speed and temperature that being (275°F and 3 Feet per minute) and (225°F

and 3 feet per minute). If one of the presets is engaged, it's corresponding LED will be illuminated.

Motor (I,J,K,L)

The motor controls are the 4 buttons on the right side of the control panel. The "Start" button will

start the motor which will run at the current speed setting. The "Speed Up" and "Speed Down"

buttons will adjust the speed setting. Pressing and releasing the button once will increment the speed

by 0.1 ft/min (0.1 meters/min). To rapidly increase or decrease the speed, press and hold the

corresponding button. To stop the motor, press and release the "Stop/Reverse" button. To reverse

the machine, press and hold the "Stop/Reverse" button. The motor will remain in reverse as long

as the button is depressed.

User Preset (M)

The Laminator is equipped with a user defined "Preset" button. This button can be used to save

a speed and temperature setting that you have defined. With the machine's speed and temperature

set to your preferred settings, press and hold the "Preset" button until the beeper sounds and the

preset light comes on. To recall this setting at a later time, press and release the "Preset" button.

Usage Counter (N)

The Laminator is equipped with a usage counter that will indicate the feet (meters) of film used.

This counter will appear on the display whenever the feet indicator light is on. This counter can

be reset to zero by pressing the "Count Reset" button once the display is showing the usage counter.

Additional Features

Keyswitch

The keyswitch (located just below the control panel) locks out the motor, allowing the machine

to remain heated; yet, preventing unauthorized usage when in the locked position.

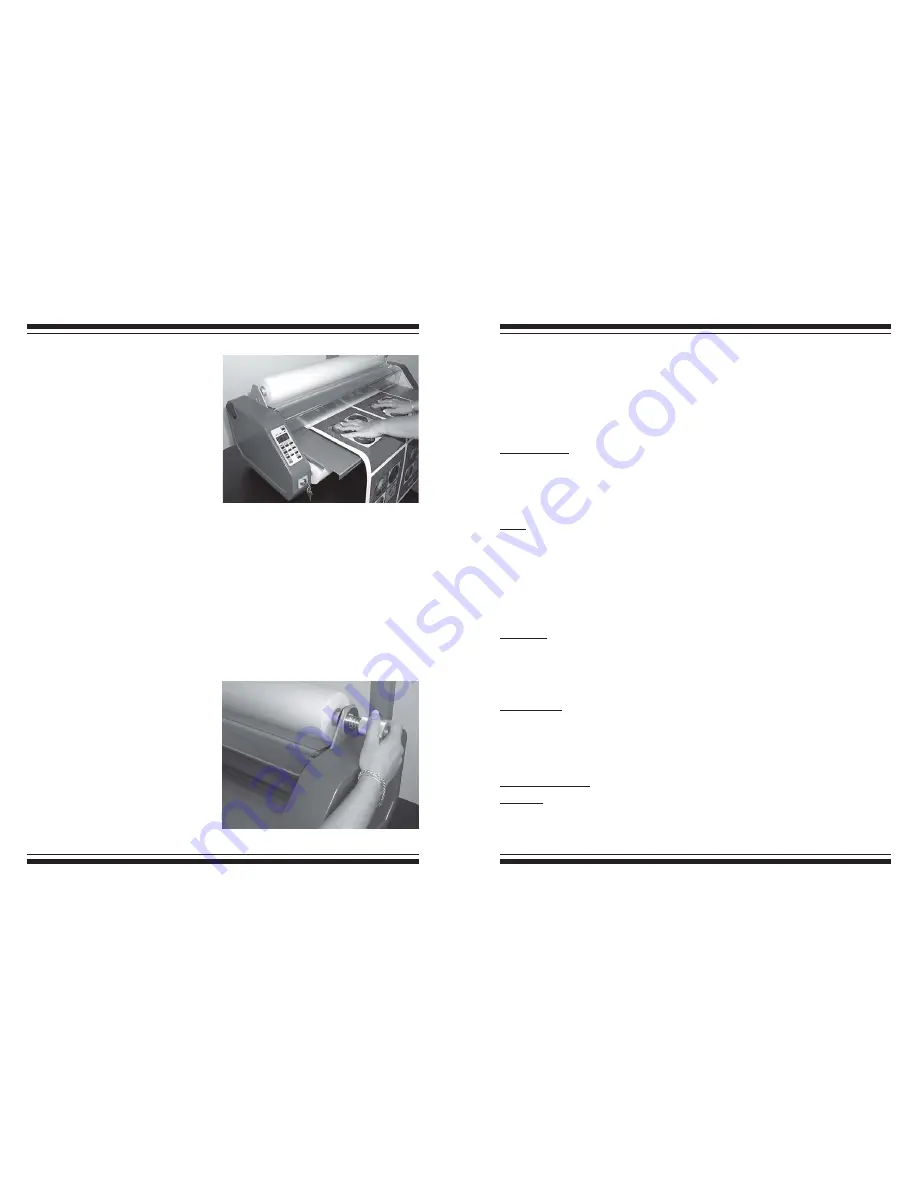

D. Laminating

After the machine is loaded with film (see B.

Loading Film: 1" Mandrel) and threaded (see

C. Threading the Film), it is ready to laminate.

Ensure that the laminator has reached the

preset temperature. This will be indicated by

the ready light being illuminated. Place

document on the feedtable and align with the

feedguide to assure straight and even

lamination. Start the motor with the "Start"

button and adjust the speed as necessary. If

necessary, adjust the supply roll tension (see

E. Supply Roll Tension Adjustment). With

both hands, guide the document into the throat of the laminator. While the document is pulled into

the laminating rollers, keep document flat on the feedtable while applying a slight back pressure.

As the document exits the rear rollers, allow 3" to 6" of film to clear the rollers at the end of your

document and turn the motor switch to stop. Using the hand held cutter, hold tension on the

laminated document and slice through the film to release the document. Multiple documents can

be run successively if desired and cut at a later time.

E. Supply Roll Tension Adjustment (A)

Top and bottom supply rolls should have about the same tension. By turning the top roll with one

hand, and the bottom roll with the other hand, it can be determined if one of the rolls is tighter than

the other.

Note: Too much tension can destroy film, documents, and damage the machine.

Adjust the tension to the minimum amount

required. Do this by loosening the tension

knobs until there is no tension on the film. With

the machine threaded and at operating

temperature, turn the motor switch to forward

and adjust the speed to the desired operating

speed. Tighten the adjusting knobs only until

the wrinkles in the film as it crosses the

heatshoe are removed.