Page 10

For technical questions, please call 1-800-444-3353.

SKU 94436

trOuBLeSHOOtIng

problem

possible cause

probable Solution

Drill does not turn on

when Trigger Switch

squeezed.

Drill Power Cord not plugged in or

1.

other power source problem.

Forward/Reverse Lever not properly

2.

set.

Check power source and connection

1.

at receptacle.

Push lever completely to left or right.

2.

Drill loses power

or stops during

operation.

Motor Carbon Brushes dirty or need

replacement.

Have a qualified technician clean or

replace brushes.

Grinding noise

when Trigger Switch

squeezed.

Drill / Impact Button not pushed in all

1.

the way.

Internal gears damaged.

2.

Push Drill / Impact Button all the way

1.

in.

Have a qualified technician repair or

2.

replace gears.

InSpectIOn, maIntenance, anD cLeanIng

WarnIng!

make sure the trigger Switch of the Impact Drill is in its “OFF” position

and that the tool is unplugged from its electrical outlet before performing any inspection,

maintenance, or cleaning procedures.

Before each use, inspect the general condition of the Impact Drill. Check for loose

1.

screws, misalignment or binding of moving parts, cracked or broken parts, damaged

electrical wiring, and any other condition that may affect its safe operation. If abnormal

noise or vibration occurs, have the problem corrected before further use. Do not use

damaged equipment.

Periodically recheck all nuts, bolts, and screws for tightness.

2.

Keep tool clean by wiping with a clean, damp cloth. Never use caustic agents to clean

3.

plastic parts.

Store tool in a clean and dry location when not in use.

4.

Periodically, using a rag and light oil, wipe drill bits and other steel parts of the drill to keep

5.

them from rusting.

Periodically blow out the motor air vents of dust and debris using compressed air.

6.

Over time, if the performance of the tool diminishes, or it stops working completely, it may

7.

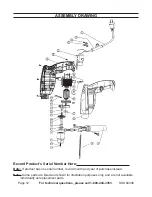

be necessary to replace the motor’s Carbon Brushes (18). The brushes are accessed by

removing Brush Cover (20). This procedure must be completed by a qualified technician.