Direct action

With direct positioner action, an increase in the output

signal produces a force on the beam moving the flapper

to cover the nozzle. The increase in nozzle back pressure

increases positioner output pressure to the actuator. The

resultant actuator stem motion is transmitted to the

force-balance spring, extending the spring until the force

exerted on the beam balances the opposing force of the

coil. As these two forces equalize, nozzle back pressure

decreases. The system then is balanced and positioner

output pressure is stabilized at an amount necessary to

maintain the control valve stem in the desired position

corresponding to the input signal value.

Reverse action

With reverse positioner action, an increase in the input

signal produces a decrease in output pressure.

Changing of action

a) Reverse the positions of the coil leads on the

terminal board (see Instruction sheet No ES

50004-000 E, page 3).

b) In case of intrinsically safe circuit, replace the coil by

another one corresponding to the new action

(Instruction sheet No ES 50004-000 E, page 3).

c) In case of flameproof housing device, the

positioner case must not be opened when the

device is energized.

d) Reverse the force balance spring position in regard to

the beam (see corresponding paragraph of page 5).

e) Calibrate after changing of action.

f)

Consult the instruction sheet No ES 50004-000 E.

3

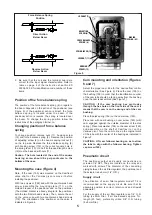

split-range operation

The following instructions apply only when the

positioners are mounted according to the diagrams of

Figure 3.

Therefore, total circuit resistance of positioners installed

for split-range operation must be in accordance with the

total load requirement of the controller. The choice of the

connecting type (in series or parallel) as well as the

positioner characteristics are according to the signal and

to the impedance of the circuits.

Masoneilan supply, in case of need, the data required

for the selection of the equipment or for its modification

in the field.

,,,

,,,

,,,

,,,

,,,

,,,

,,,

yyy

yyy

,

,

,,

yy

,

,

,

,

,

,,

,,

yy

yy

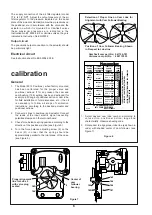

SUPPLY

PRESSURE

OUTPUT

PRESSURE

,

NOZZLE

BACK PRESSURE

SUPPLY

PRESSURE

OUTPUT

TO ACTUATOR

FLAME

ARRESTOR

NOZZLE

FORCE

BALANCE

SPRING

BEAM

FLEXURE

STRIP

COIL

MAGNET

RELAY

O-RING

MOLDED

BRACKET

TERMINAL

BOARD

FORCE BALANCE

SPRING LEVER

CAM FOLLOWER

BEARING

Figure 2– Diagram of Pneumatic Circuit