FIG.4

14

8. PREPARING THE WELDER

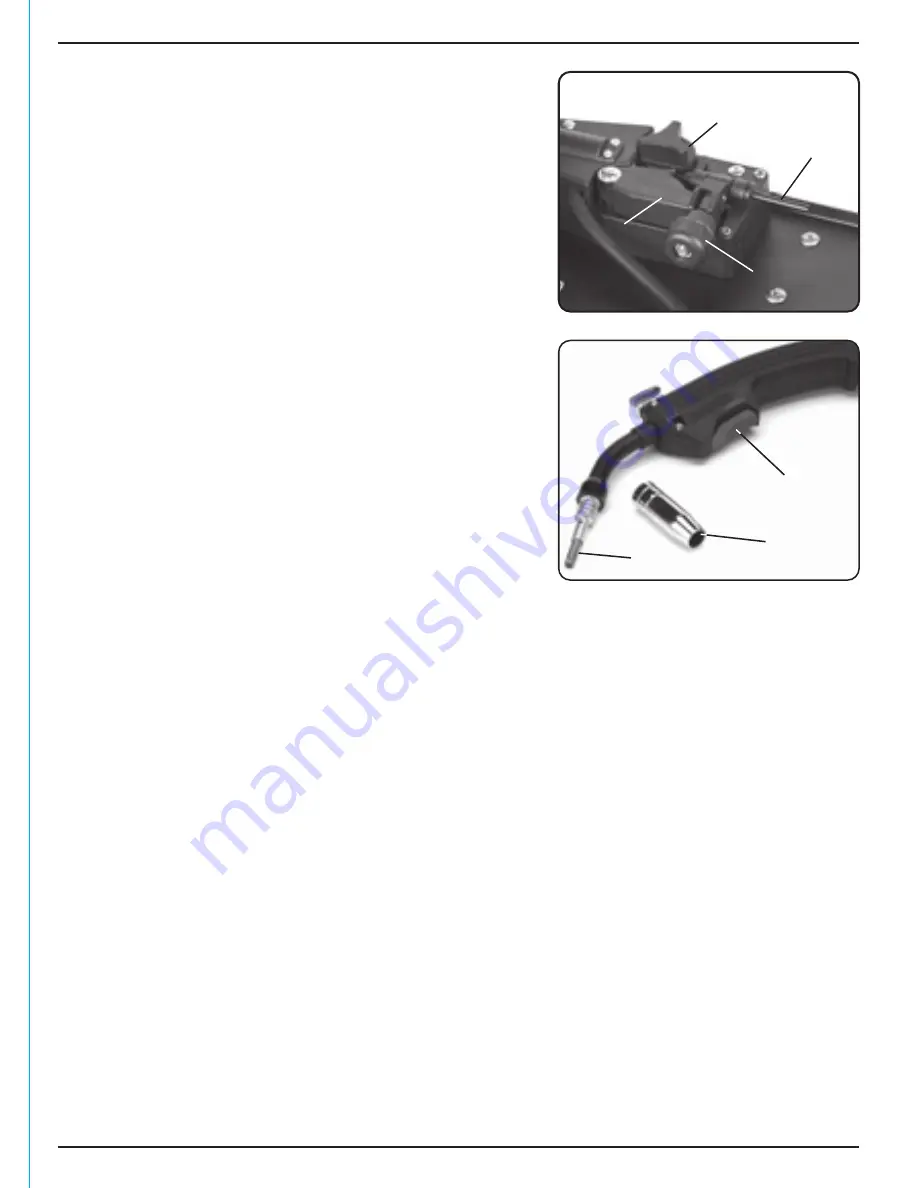

8.3 WIRE DRIVE UNIT – FIGS. 4 – 5

The wire is fed down the torch lining by the wire drive

motor. Tension of the rollers must be adjusted

correctly to prevent the filler wire slipping or jamming.

iv. Loosen tensioner

anticlockwise enough to

swing it outwards and lift arm

, moving the

tension roller

.

v. Trim 10cm of wire and discard it, before

flattening out the next 15cm. Do not let the

wire lose tension.

vi. Pass the filler wire through the guide

and

over the top of the drive roller fitted under

securing nut

. The drive roller comes with

two grooves for different wire gauges. Remove

nut to see the groove size that is

NOT

in use.

Note:

The wire must sit in the appropriate

groove for the wire gauge. The groove size is

etched on the side of the roller. To reverse the

roller, remove nut and flip the drive roller over

before refitting nut

.

vii. Make sure the wire is well inside the torch liner

before closing the arm

and tensioner

.

viii. Connect the welding machine to the power

supply. Position the switch to ‘on’.

ix. Unscrew/remove the gas shroud

and with

a small spanner unscrew and remove the tip

. Pull the trigger

and observe

the wire feed mechanism. If the wire is being fed correctly it will come out of the

swan neck. Pass the tip over the wire and secure back onto the swan neck. Do not over

tighten. Resecure the gas shroud and trim the wire back as required.

Note:

Ensure the tip size matches the wire size prior to installing.

FIG.5

Содержание MIG100GG

Страница 22: ...22 NOTES ...

Страница 23: ...23 NOTES ...