– 15 –

9. OPERATION & USE

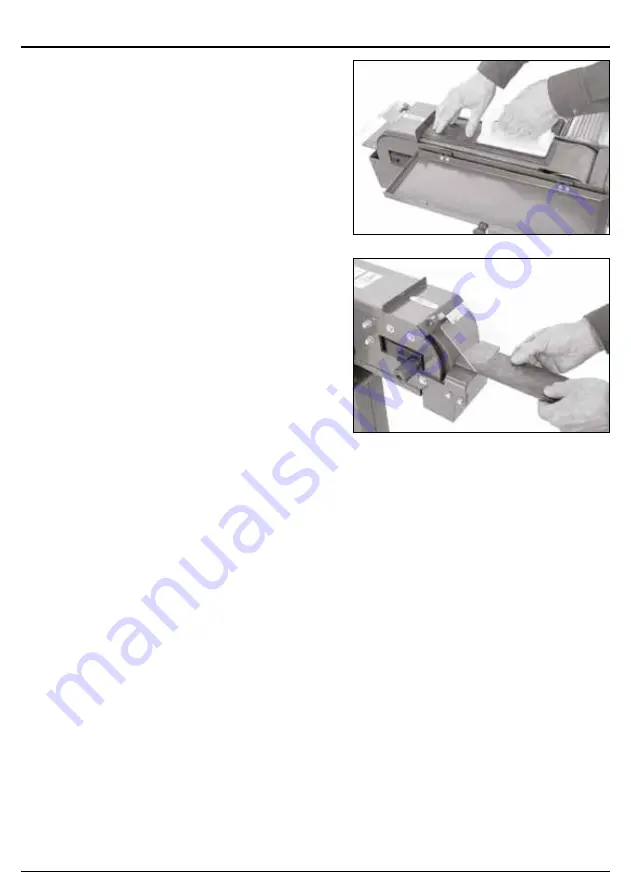

9.3 FLAT GRINDING – FIG.11

Flat grinding operations can be performed directly

on the belt against the platen. Always use two

hands to control the workpiece and use the work

stop to support it.

– Connect the machine to the power supply, turn

it ON and allow it to reach full speed.

– While supporting the workpiece against the

work stop, slowly feed it into moving belt with

light even pressure. Use a push block to

maintain control of the workpiece. DO NOT

force the workpiece against the belt.

Caution! The moving belt can cause serious

personal injury if it comes in contact with fingers,

hands or other body parts. Use extreme care to

provide a safe distance between the belt and any

part of your body.

9.4 END GRINDING – FIG.12

End grinding operations are performed on the front

end of the grinder with the workpiece pressing

against the contact wheel. For additional control

over the workpiece, use the work rest to support

workpieces during operations. Always use two

hands to maintain best control.

– Connect the machine to the power supply, turn

it ON and allow it to reach full speed.

– Position workpiece on work rest if feasible.

– Use both hands to maintain control of the

workpiece and slowly feed it into the contact

wheel at the end of the moving belt, with light,

even pressure. DO NOT force the workpiece

against the belt.

Caution! The moving belt can cause serious

personal injury if it comes in contact with fingers,

hands or other body parts. Use extreme care to

provide a safe distance between the belt and any

part of your body.

9.5 SAFETY NO VOLT SWITCH

This machine is fitted with a safety ‘no volt switch’.

Lift cap to access standard on and off switch, if the

no volt stop button has been used to stop the

machine.

FIG.11

FIG.12