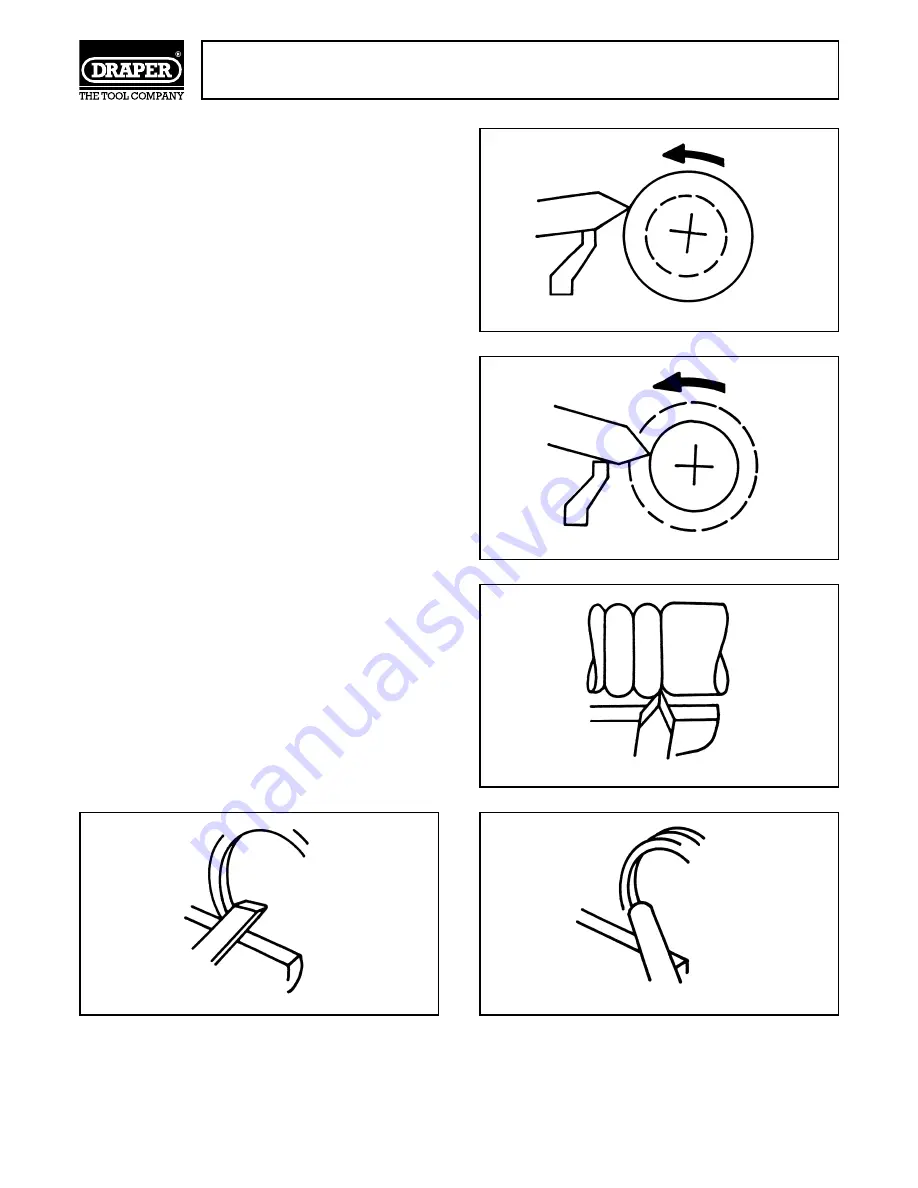

WOODTURNING OPERATIONS cont’d

USING A PARTING CHISEL

A parting chisel has one primary purpose – to cut

straight into the workpiece as deep as desired, or all

the way through the workpiece to make a cut off. This

is a very narrow chisel approximately

1

⁄

8

″

wide and is

shaped to cut its own clearance, so the cutting edge

will not burn. But when used as a scraper, it should

be backed off at regular intervals to prevent

overheating. See Figs. 53 and 54.

USING SCRAPING CHISELS

Finally, three more types of chisel should complete

the list of chisels for the average craftsman, these

and

1

⁄

2

″

spear point,

1

⁄

2

″

round nose and a 1

″

flat node.

Each of these chisels may be purchased in various

sizes, (refer to the Draper Catalogue) for special

jobs. All of these are very useful for diameter

scraping (see Figs. 55, 56 and 57) operations and for

circumference scraping, when cutting methods

cannot be employed.

The spear point chisel is used for fine scraping and

delicate operations such as the forming of beads,

parallel grooves and shallow vees. Edges and bowl

contours can be rounded with the round nose chisel.

Any flat surface can be scraped with the flat nose

chisel.

- 21-

Fig.53.

Fig.54.

Fig.55.

Fig.57.

Fig.56.

CUTTING

SCRAPING

SPEAR POINT

FLAT NOSE

ROUND NOSE