Foamer Manual

6

AFTER USE INSTRUCTIONS

TROUBLESHOOTING

1. It is recommended to run a gallon of fresh water through the unit after each use. With the

discharge ball valve open run the unit until the gallon of water has gone through the unit and

discharged out of the discharge hose.

2. Disconnect the air line from the air fitting and relieve any remaining pressure in the system by

having the discharge ball valve in the open position.

3. Close the discharge ball valve when all the pressure is relieved from the system.

1.

Check for proper air pressure (60psi or more into unit, 60 psi on AG100).

2.

Check for proper air flow. Foamer needs 5 CFM

minimum

and more with longer hose lengths.

3.

Check air inlet filter for debris such as water, oil, or rust particles. Clean by pressing up on the

bottom of the filter.

4. Ensure that the discharge hose is not kinked in any way that would reduce or obstruct solution

flow.

5.

Check for plugged strainer. Replace strainer if necessary,

STRAINER MUST BE USED

.

6.

If

wet foam/dry foam

valve is open too far the pump will not cycle properly due to lack of air

pressure. If this occurs, reset valve as described in operation instruction #4.

7.

Make sure proper foaming chemical and concentration is being use.

8.

If air passes through the pump without cycling, replace pump.

9.

If foam solution backs up into air filter the check valve needs to be replace.

10. If foam comes out wet no matter where the

wet foam/dry foam

valve is positioned the check

valve may need to be replaced.

11. If unit foams at a reduced pressure:

A. Check the air supply into the unit. If it is low, turn the foam unit off until the compressor

can catch up.

B. If the air supply is 60psi or above, check the internal air gauge which should read near

60psi. If the gauge is more or less than 60psi, adjust the pressure by turning the knob on

the top of the regulator.

Содержание FM20

Страница 1: ...FOAMER FM20 FM50 Foamer Owners Manual FM50 FM20...

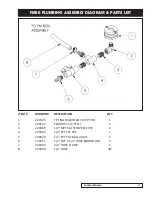

Страница 7: ...FM BOX ASSEMBLY DIAGRAM Foamer Manual 7...

Страница 12: ...Foamer Manual 12 FM20 FRAME ASSEMBLY DIAGRAM...

Страница 14: ...Foamer Manual 14 FM50 FRAME ASSEMBLY DIAGRAM...