voltage is present at the switch and the LED does not illuminate, the residual current

circuit-breaker must be replaced. The insulation test should be carried out using test

devices according to DIN EN 61557-2. To carry out a simple insulation test for the

electrical system, we recommend supplying power ‘from above’ for type B switches.

This means only the switch needs to be switched off during the test and the measure-

ment can take place on the system side. Performing an insulation test when the re-

sidual current circuit-breaker is switched on or on the side with the odd-numbered

terminals can lead to erroneous measurement values as a result of the internal adap-

tor. In this case, we recommend disconnecting the switch for the duration of the test.

Important information on operation of an AC-DC sensitive residual current circuit-

breaker (DFS 2/4 B/B+) with electronic equipment

(such as frequency converters, inverters etc.)

1. Electronic equipment and its associated EMC protective provisions,

such as integrated or in series-connected EMC filters, as well as shielded cables,

can produce high capacitive leakage currents.

2. The maximum number of items of electronic equipment connected

downstream of the DFS 2 B/DFS 4 B is based on the level of leakage currents that occur.

Excessive leakage currents may lead to undesired tripping. Relevant information

concerning the leakage currents that are produced can be requested from the

manufacturers of the electronic equipment.

3. During operation with frequency converters, long, shielded motor cables

may lead to high leakage currents in the event of the controller release of

the frequency converter, which may lead to undesired tripping. If neces-

sary, a sinusoidal output filter should then be used directly behind the

frequency converter (before the shielded motor cable).

4. When switching electrical systems with electronic equipment on and off,

it is possible that very high surge leakage currents will be produced, which will

lead to tripping in the event of an appropriate duration. The switch-on and

switch-off operations should be kept as short as possible. Quick-switching,

all-pole contactors or switches with stored energy operating mechanisms are

suitable (manual rotary switches should not be used).

5. According to the instructions, a 3-conductor EMC filter should only be connected

in series with the relevant electronic equipment. So that the filter effect is not

impaired, under no circumstances should further single-phase consumers such as

incandescent bulbs be connected on the output side of the EMC filter.

6. As a rule, different clock frequencies (chopper) can be selected in the case of elec-

tronic equipment. In an unfavourable case, the clock frequency may lead to a ten-

dency to oscillation in an upstream EMC filter and therefore to greatly increased

leakage currents, which then result in a tripping of the DFS 2/4 B. In this case, the

clock frequency must be changed.

7. Frequency converters with an integrated EMC filter often only allow a maximum

shielded motor cable length of 5 to 10 m. Longer cable lengths lead to greatly

increased leakage currents and to the ineffectiveness of the integrated EMC

filter. The manufacturer's specifications must always be observed for the

frequency converter.

Guarantee

All professionally installed, unaltered devices are covered by warranty during the

statutory guarantee period from the day of purchase by the end user. The guaran-

tee is not applicable to damage incurred during transport or caused by short-circuit,

overloading or improper use. In the event of defects in workmanship or material,

which are discovered within the guarantee period, the company will provide a repair

or replacement free of charge. The guarantee will be rendered null and void if the

device is opened without authorisation.

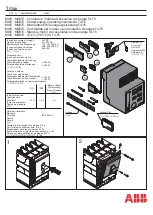

Wiring diagrams

2

4

1

3

~

1/N

7/N

3

5

8/N

2/N 4

6

~

V

two-pole (grey: type B only)

V

four-pole, neutral on left or right,

depending on device version

(grey: type B only)

Installation and operating instructions

for residual current circuit-breakers

of model range DFS 2 and DFS 4

These installation and operating instructions are aimed at qualified

electrical specialists. The installation of devices of this type is not ap-

propriate for electrical laypersons due to the considerable potential

dangers. These installation and operating instructions must be re-

tained, so that they can be referred to at a later stage. The operator of

the electrical installation must be informed about the use and function

of this protective device.

Application instructions and warnings

The following notes and warnings must be observed in order to ensure safe operation:

1. Devices with visible damage must not be installed or used.

2. Operation must only occur under normal ambient conditions free of corro-

sive gases in order to preserve the correct tripping function in the long term.

Corrosive gases are chlorine, ammonia and sulphurous air, for example. Residual

current circuit-breakers with "HD" specification are recommended for environ-

ments affected by corrosive gases.

3. The user must be made aware of regular function testing using the test key T.

4. The function test with the test key is not a substitute for regular testing of the

electrical system.

5. Erroneous tripping due to operation related leakage currents or atmos-

pheric interference cannot be ruled out with absolute certainty. The conse-

quences must be considered and countermeasures taken where necessary.

Selective residual current circuit-breakers as well as surge protection measures

and system optimisations can provide a remedy.

6. If the RCCB cannot be switched on, or if the consumer network is not connected,

the device must be replaced.

7. Disposal is subject to the statutory regulations of the European Union (WEEE/

German Electrical and Electronic Equipment Act).

For further information and data sheets, please visit www.doepke.de and search by

the article number or scan the QR code on the front of the housing.

Intended use:

DFS 2 and DFS 4 series protective devices are residual current circuit-breakers

without integrated overcurrent protection. They provide protection through auto-

matic switch-off in electrical systems, e.g. in accordance with VDE 0100 part 410.

They meet the requirements for residual current protection in accordance with their

characteristics on the name plate. The switch-off function can be tested using a

push-button which is also accessible to laypersons. Regular testing can also increase

the endurance of the circuit-breaker, as the mechanism of the latch is moved when

tripped in addition to the electrical test.

Electrical connection and installation:

The electrical connection must be as shown in the wiring diagram and must comply

with the terminal designation on the device. With type B devices, it is preferable for the

power to be supplied to the odd-numbered terminals (simplified insulation measure-

ment). If the device is to be operated without using all poles, it is essential (in order to

ensure the connection is correct) to observe the position of the test key as per the wir-

ing diagram and the operating voltage range of the test circuit in accordance with the

data sheet. DFS 4 devices have an N-left design as standard. N-right devices have an

‘R’ in their designation. Scrape and grease aluminium conductors immediately before

connection. The device must be installed on a mounting rail (TS 35) according to

DIN EN 60715 in distribution boards that must ensure protection against direct con-

tact (which may be required depending on the location of use) and protection against

environmental influences.

Testing and functional check

A simple function test with the assistance of test key T should be carried out after

the mains voltage and the circuit-breaker are switched on. When the key is pressed,

the DFS 2/DFS 4 must disconnect without delay; the toggle is then in centre position.

Resetting to position ‘1’ is only possible if the toggle has first been moved down to

position ‘0’. The operation indicator beneath the toggle indicates the status of the

contacts: red = closed, green = open. This test must be carried out at least every six

months where the device is used as intended and must be repeated every working

day for non-stationary systems according to the regulation. If tripping does not oc-

cur, the device must be replaced immediately. The operator must be informed of this.

All additional tests are covered by the prescribed acceptance test. Tests should be

carried out according to DGUV Regulation 3 (BGV A3) depending on the location.

The green LED on the front of the housing of the DFS 2 B/DFS 4 B AC-DC sensitive

residual current circuit-breaker indicates that the AC-DC sensitive residual current

detection is active. If the LED does not illuminate, then only tripping in the event of

type A residual currents is guaranteed. If this is the case, it should be checked first

if there is operating voltage of min. 50 V AC between two active conductors. If this

Doepke

3930290

|

12/2018

|

Doepke Schaltgeräte GmbH, Stellmacherstraße 11, D-26506 Norden

DE EN