23

CARE AND MAINTENANCE

Stop engine and remove ignition key for safety. Wear heavy, thick

gloves when holding onto cutter blade, avoid the sharp edge of the

blade.

MOWER BLADES

:

Check sharpness of mower blades after every 10 hours of operation. To sharpen

blades, proceed as follows.

A.

Remove bolt and flat washer mounting blade on shaft. Remove blade.

B.

Blades should be discarded when worn excessively.

C.

Sharpen blade with a hand file, electric grinder or blade sharpener. Wear

gloves and eye protection when sharpening. Grind blade at original 25

degree bevel.

D.

Check balance of blade by positioning the blade on a nail or blade balance

pedestal. Grind the blade on the end that is heavier until both sides balance.

E.

Install blade, flat washer and bolt. Make sure to tighten bolt to 60 ft. lbs.

New Blade

25 degrees

When notch starts,

discard blade

DANGEROUS!

DO NOT USE

BLADE IN THIS

CONDITION!

BELTS:

Check belts every 50 hours. Replace any belts found to be in poor condition.

CAUTION

Содержание ZTR 8000 Series

Страница 1: ...1 Page 8000 SERIES Diesel Version ZTR MOWERS Operator s Manual 2001...

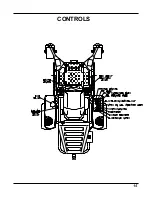

Страница 15: ...15 CONTROLS...

Страница 34: ...34 NOTES...