P a g e

|

3

DSEFO144-12 Rev 8/19

ASSEMBLY INSTRUCTIONS

1)

The antenna components should be removed carefully from the shipping container and

the individual parts counted and checked for completeness. Be careful to check all tubing

pieces for elements and hardware that may be packed inside.

In the following steps, apply a small amount of the supplied Anti-Seize to the boom joints:

2)

The boom consists of three pieces of tubing. The rear boom section has the large hole

for the driven element in it. The larger diameter center boom section (1 3/8" dia.) must be

connected to the rear section. Insert rear section where marked with like colors, align the #8

hardware mounting holes and slide the stainless steel worm clamp over the slotted portion of

the center boom piece. An 8-32 X1 3/4" machine screw, lock washer and hex nut complete the

process. Tighten all hardware then proceed with the front boom piece. That connection with

the mid boom piece is also marked with like colors. Similarly attach the front boom section as

you did the rear.

3)

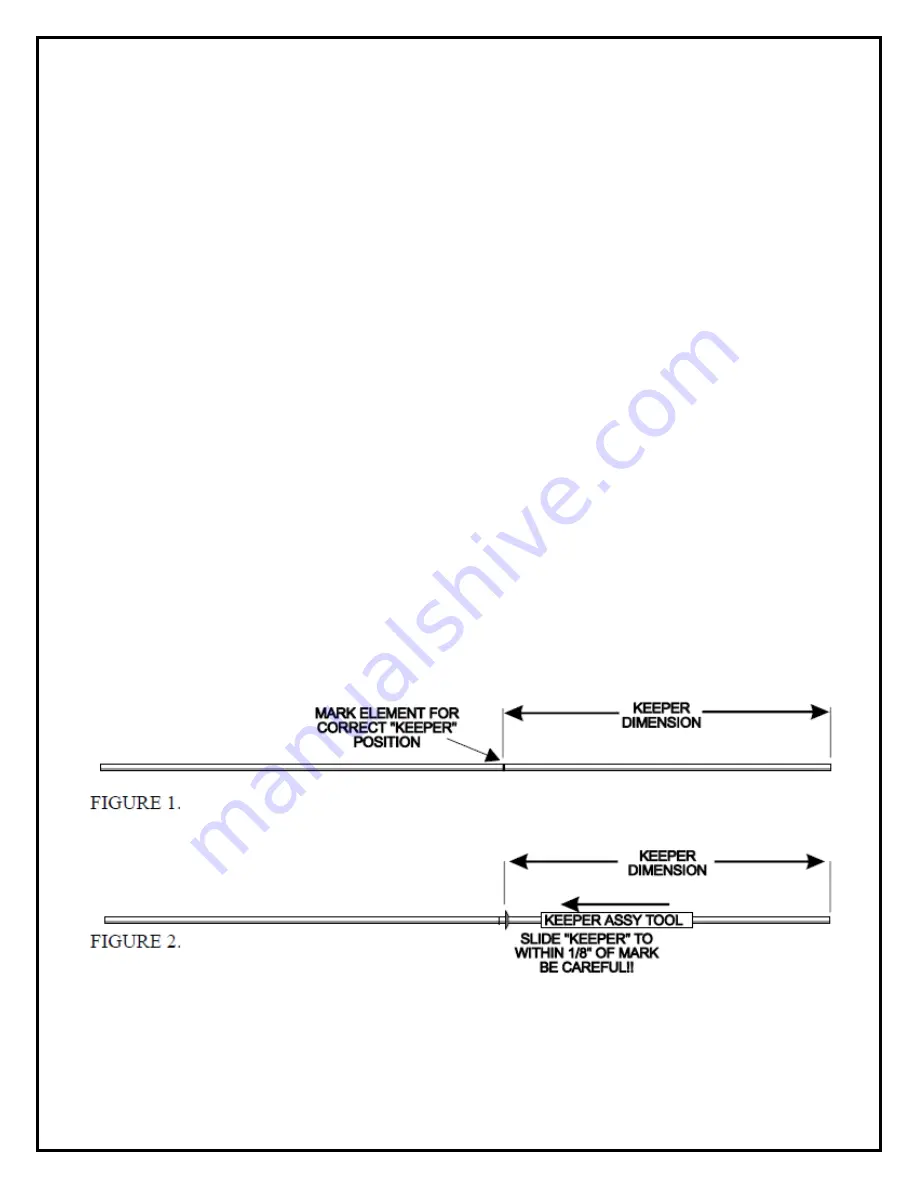

The element bundle contains all of the elements needed for assembly. Take time to

inventory each one and check off each dimension with Table 1. Some elements vary by 1 or

2mm in overall length, so extreme care in measuring is called for here. Arrange elements in

order of descending size and mark each element with a scribe for proper location of the

“keeper” (See Table 1 and Figure 1). The reflector is the longest element, and each

succeeding director is slightly shorter. DIR # 10 is the shortest. The keeper must be installed

as shown in Fig. 2. Using the aluminum tubing tool supplied, slide the keeper to within 1/8

” or

3mm of the scribed line. Final adjustment will be done on the antenna. Note that the keeper is

a one-way device only. If you go past the scribed line, you must continue to the element end

and start the process over. Place the first keeper on all elements.

4)

You are now ready to install the elements on the boom. You must start at one end and

work your way, in order, to the far end of the boom. Lay out the elements in ascending or

descending order as appropriate. Install a black insulator in each side of the boom piece at

the starting end, and slide the correct element through the two insulators. Obtain a second

keeper and install that keeper on the opposite end of element #1 from the pre-installed keeper.

Содержание DSEFO144-12

Страница 5: ...P a g e 5 DSEFO144 12 Rev 8 19 FIGURE 4...

Страница 6: ...P a g e 6 DSEFO144 12 Rev 8 19...