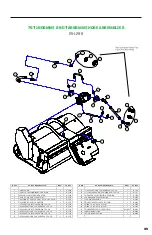

TROUBLESHOOTING

CONTINUED ON NEXT PAGE

PROBLEM

POTENTIAL CAUSE

SOLUTION

Excessive

Vibration

Loose hardware

Check and torque all hardware.

Cutting assembly

unbalanced and/or

is damaged

Check for damaged knives, cutting

shaft, etc.

Check for wire & other debris

entangled in the the cutting assembly.

Vegetation buildup

Disengage mower and back up. Shut

down the mower and clear it manually.

•

DO NOT

use extremities to

remove debris.

Skid-steer /

compact track

loader is operating

on standard flow

hydraulics

Operate skid-steer / compact track

loader on high flow hydraulics.

Loose belt(s)

Belt is stretched or badly worn;

replace as needed.

Flail mowers are equipped with

automatic self-tensioners; call

Diamond Mowers for assistance.

Misaligned pulleys

Correct pulley alignment.

PROBLEM

POTENTIAL CAUSE

SOLUTION

Mower Will Not

Start or Run

No hydraulic oil flow

to the mower

Verify hydraulic hoses are installed

correctly. Verify skid-steer / compact

track loader high flow hydraulics are

engaged.

skid-steer / compact

track loader

hydraulic oil fluid

level low

Check and add hydraulic oil per the

skid-steer / compact track loader

operator’s manual.

skid-steer / compact

track loader

hydraulic system

does not match the

mower’s hydraulic

requirements

Verify the skid-steer / compact track

loader hydraulic system matches

the mower’s hydraulic requirements.

Verify hydraulic hoses are installed

correctly. Verify skid-steer / compact

track loader high flow hydraulics are

engaged.

27

Содержание FLAIL MOWER

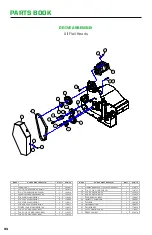

Страница 29: ...PARTS BOOK 29...

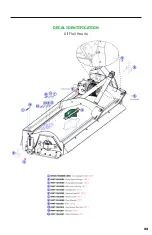

Страница 33: ...DECAL IDENTIFICATION All Flail Heads 33...

Страница 40: ...DIAMONDMOWERS COM DIAMONDMOWERS COM 15 1101 DLF MANUAL...