26

English

CODE

POSSIBLE CAUSE

POSSIBLE SOLUTION

13

Carbon build-up in pump

Contact a D

e

WALT factory service center or a D

e

WALT authorized

service center.

14

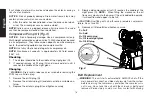

Belt to tight

Check belt tension, see

Adjusting Belt Tension

under

Maintenance.

15

Pulley misalignment

See

Motor Pulley/Flywheel Alignment

under

Maintenance

.

16

Pump oil is low

Add full synthetic, non-detergent air compressor oil to pump. See

Compressor Pump Oil

under

Maintenance.

17

Detergent type oil being used in pump

Drain oil and refill pump with full synthetic non-detergent air com

-

pressor oil.

18

Extremely light duty cycles

Run unit for longer duty cycles. It is recommended to run at high

throttle 50-75% of the run time and idle for 25% of the run time.

19

Piston rings damaged or worn

Contact a D

e

WALT factory service center or a D

e

WALT authorized

service center.

20

Cylinder or piston damaged or worn

Contact a D

e

WALT factory service center or a D

e

WALT authorized

service center.

21

Compressor cylinder finish worn

Contact a D

e

W

ALT

factory service center or a D

e

WALT authorized

service center.

22

Water in pump oil

Drain oil and refill pump with full synthetic non-detergent air com

-

pressor oil.

23

Low voltage/motor overload

C

heck that power supply is adequate and that compressor is

on a dedicated circuit. If using extension cord, try using without.

If compressor is connected to a circut protected by a fuse, use

dual element time delay fuses (Buss Fusetron type “T” only).

24

Restricted air passages

Inspect and replace transfer tubes or check valve, as

required.

Содержание DXCMV7518075

Страница 90: ...NOTES ...

Страница 91: ...NOTES ...