Model

P1000

Cat. No.

ddF211000P

P1000

3

FuncTioning in STeel

the load performance of a powder

actuated fastener when installed into

steel base materials is based on the

following factors:

1. thickness of the steel

2. tensile strength of the steel

3. shank diameter of the fastener

4. depth of point penetration through

the steel

5. fastener spacing and edge distance.

when a powder actuated fastener is driven into steel, it

displaces the steel laterally 360˚ around the shank of the

fastener. since steel is an elastic material, it presses back

against the shank of the fastener to hold it in place. as the

diameter of the fastener shank is increased, the load capacity

obtained will generally increase provided the steel thickness

is sufficient to accept the fastener. to further increase

fastener performance in steel, some fasteners have a knurled

shank which allows the steel to form a key lock into the

grooves to provide higher capacities than those obtained with

a smooth shank. for optimum performance, the fastener

point should completely penetrate the steel. normally, a

minimum of 1/4” is allowed for the point length. an increase

in performance can be expected until the fastener no longer

completely penetrates through the steel. at this point, the

elastic properties of the steel cause a compression force to

be developed at an angle against the fastener point which

reduces load capacity. in thicker steel base materials,

adequate load capacities may be obtained for applications in

which the point of the fastener does not fully penetrate the

steel. job site performance tests are recommended.

fasteners should not be used in areas that have been

welded or cut with a torch as these procedures may have

caused local hardening of the steel. over driving of the

fastener should be avoided as the rebound created may

reduce the load capacity or cause damage to the fastener.

when fastening into unsupported long steel members, it may

be necessary to provide support in the area of the fastening

to prevent spring action which can cause inconsistent

penetration and a reduction in load capacity.

SuiTaBle BaSe MaTeRial

while powder actuated fasteners can be used

successfully in concrete, certain masonry materials, and

a 36 steel, some materials are completely unsuitable.

fasteners should never be fired into hard or brittle materials

such as cast iron, tile, glass, or rock. these materials

can shatter easily resulting in a potential safety hazard. in

addition, soft base materials such as wallboard, plaster,

or wood are not appropriate as the fastener could pass

completely through these materials. the user should never

guess when fastening into any base material. failure to

follow the recommended installation and safety guidelines

can result in severe injury or death to the tool operator and/

or bystanders.

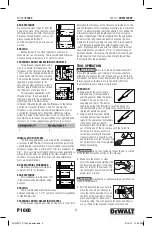

cenTeR punch TeST

a center punch test should always

be performed to determine the suitability

of the base material for a powder

actuated fastening. this test is relatively

simple and can help to insure a safe,

successful fastening. be sure to wear

the appropriate eye protection when

performing this test. to begin, select the

fastener to be used for the job. then,

place the point of the fastener against

the proposed base material. strike the

fastener with a single hammer blow,

then examine the point. if the point of

the fastener is not blunted and the base

material has a clear point indentation,

it is acceptable to proceed with the first

test installation.

use of a powder actuated system is

not recommended if the following occurs

during the center punch test:

1. the fastener point has been blunted.

this indicates that the base material

is too hard.

2. the base material cracks or shatters. this indicates that

the base material is too brittle.

3. when using an average hammer blow, the fastener

penetrates the base material easily. this indicates that the

base material is too soft.

FaSTeneR inSTallaTion RequiReMenTS

it is important to understand the required minimum base

material thickness requirements along with the minimum

spacing and edge distance requirements. failure to follow

these requirements can result in an unsuccessful fastening

and create a safety hazard.

BaSe MaTeRial ThickneSS

concrete base material should be at least three (3)

times as thick as the fastener embedment penetration. if

the concrete is too thin, the compressive forces forming at

the fasteners point can cause the free face of the concrete

to break away. this can create a dangerous condition from

flying concrete and/or the fastener and also results in a

reduction of fastener holding power. for applications in the

face shell of concrete masonry block, select a fastener length

which will not exceed the thickness of the face shell.

FaSTeneR peneTRaTion guiDe

the following table lists typical

embedment or penetration depths

expected in the base materials listed.

the penetration will vary depending on

the density of the material. this table

should be used as a guide since the

consistency of these materials varies.

when in doubt, a job site performance

test should be conducted.

DenSiTy

Typical BaSe MaTeRial

peneTRaTion

soft masonry

concrete block

1” – 1-1/4”

average concrete

Poured concrete

3/4” – 1”

dense concrete

Pre-stressed/pre-cast concrete

5/8” – 3/4”

Point

Flattens

No

Indent

Surface

Shatters

Material

Cracks

Fastener Sinks in

with Average

Hammer Blow

2

3

1

Penetration

3x

Penetration

POW2271_P1000_booklet.indd 3

3/10/14 12:43 PM

Содержание DDF211000P

Страница 30: ...P1000 Model P1000 Modelo P1000 ModÈlE P1000 30 POW2271_P1000_booklet indd 30 3 10 14 12 43 PM ...

Страница 31: ...P1000 Model P1000 Modelo P1000 ModÈlE P1000 31 POW2271_P1000_booklet indd 31 3 10 14 12 43 PM ...

Страница 32: ...P1000 Model P1000 Modelo P1000 ModÈlE P1000 32 POW2271_P1000_booklet indd 32 3 10 14 12 43 PM ...