Page 8 SB-6-159-H

MINIMUM PIPE SIZE RECOMMENDATIONS ChART

Compressor

Compressor

Main

Min. Pipe

Size

Capacity

Air Line

Diameter

1-1/2 and 2 HP 6 to 9 CFM

Over 50 ft.

3/4"

3 and 5 HP

12 to 20 CFM

Up to 200 ft.

3/4"

Over 200 ft.

1"

5 to 10 HP

20 to 40 CFM

Up to 100 ft.

3/4"

100 to 200 ft.

1"

Over 200 ft.

1-1/4"

10 to 15 HP

40 to 60 CFM

Up to 100 ft.

1"

100 to 200 ft.

1-1/4"

Over 200 ft.

1-1/2"

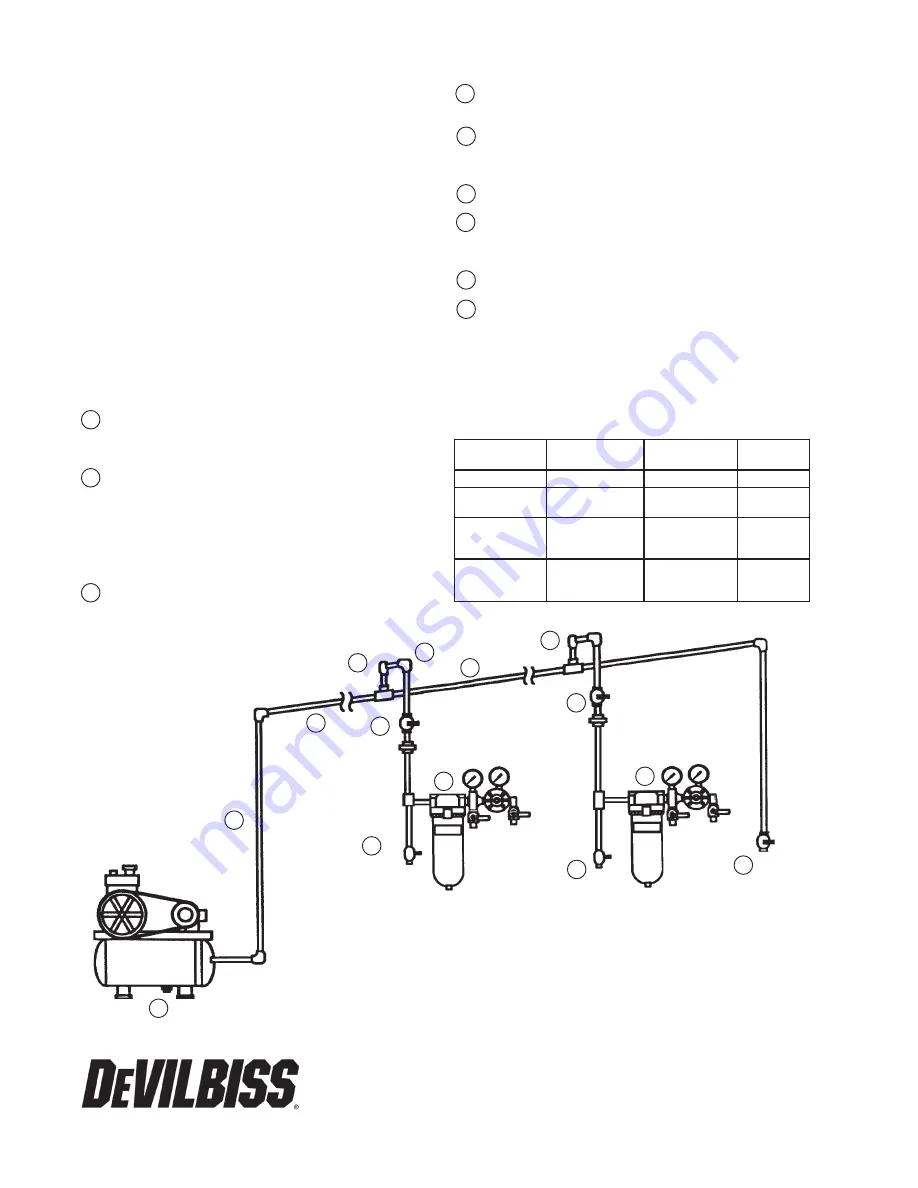

CLEANAIR™ AIR PIPINg RECOMMENDATIONS

The plumbing of your shop air lines is very important. Correct

installation is necessary for the proper performance of your

equipment - for an uncontaminated air supply and for sufficient

pressure to your breathing apparatus and spray gun.

Correct air line piping is so important that this one factor alone

can reduce contaminates in your air supply up to 75%. Reduc-

ing contaminates to the filter also reduces the frequency of filter

replacement, maintenance, and of course reduces the risk of

contaminates to the painter and paint supply.

Even the size of the pipe is critical. Using pipe that is too small

in diameter can cause a pressure drop.

Example: If an air compressor delivers 100 psi through a 100'

pipe 1/2" in diameter, there's greater pressure drop than if a 3/4"

diameter pipe were used. The chart on the back page provides

recommended piping sizes..

AIR LINE PIPINg gUIDE

1 After leaving the air compressor, the air line should go

straight up as high as possible. This helps prevent any water

from leaving the compressor and travelling through the

pipe.

2 Horizontal pipes should slope back towards the compressor

at least 4" per 50'. As warm air leaves the compressor, it

cools and thereby water vapor condenses as it travels

through the pipe. This water, a problem in itself, also can

cause scaling and rust inside the piping. The backward

sloping of the pipe helps drain these contaminates back

toward the compressor drain which should be drained

daily.

3 A take off should come from the top of the main air supply

line at each air drop. This reduces the risk of water and other

contaminates from traveling down the drop into the water

separator.

4 Pipe diameter must be of sufficient size for the volume of

air being passed as well as the length of pipe used. This

will minimize pressure drop. See chart.

5 First air drop should be at least 25' from the compressor,

although 50' is optimum. This allows the compressed air

to cool so any condensation can occur before it gets to the

air filter.

6 Shut-off valves are installed before the point of use filter.

This allows air to be shut off for filter maintenance.

7 Point-of-use filter - Strongly recommended for eliminating

any remaining contaminates. The DeVilbiss CleanAir type

air control units are most effective in providing a truly

contaminant-free air supply.

8 Drain valve - The daily draining of the system at each outlet

disposes of the contaminants that build up in the air supply.

9 Drain the compressor trap daily if equipped with a manual

drain.

Proper maintenance of the air compressor can reduce airborne

contaminants such as particles and oils, and reduce heat and

operating cost. Check air filters, oil level and perform regular

maintenance per operators manuals.

1

6

5

8

3

2

6

9

8

For normal

compressed

air systems

having average

amounts of

airborne con-

taminants.

Add final

drain leg for

extremely

wet/dirty air.

Add drain leg with

blow down valve at

each station when

compressed air is

extremely wet/dirty.

Figure 13 - CleanAir™ Piping

4

8

7

7

3

5/12 ©2012 DeVilbiss All rights reserved. Printed in U.S.A.