When 3" pipe is used, connect a 2" to 3" coupling to the 2" pipe.

For proper installation of venting/exhaust pipe:

1. Position the supplied venting gasket on the top panel

exhaust.

2. Slowly slide a 2" diameter pipe throught the venting

gasket. This step will be easier if pipe is chamfered.

3. Position this venting pipe length on the rubber vent

collector and tighten the collar.

4. Install the remaining vent pipes. It is recommended that

all pipes be cut, prepared, and preassembled before

permanently cementing any joint.

5. Working from furnace to outside, cut the pipe to the

required length(s).

6. Deburr the inside and outside of the pipe.

7. Chamfer the outside edge of pipe for better distribution of

primer and cement.

8. Clean and dry all surfaces to be joined.

9. Check dry fit of the pipe and mark insertion depth on the

pipe.

10. After the pipes have been cut and preassembled, apply a

generous layer of cement primer to the pipe fitting socket

and end of the pipe to insertion mark. Quickly apply

approved cement to end of the pipe and fitting socket

(over primer). Apply cement in a light, uniform coat on

the inside of socket to prevent build-up of excess cement.

Apply second coat.

11. While cement is still wet, twist pipe into the socket with

1/4” turn. Be sure the pipe is fully inserted into the fitting

socket.

12. Wipe excess cement from the joint. A continuous bead

of cement will be visible around perimeter of a properly

made joint.

13. Handle pipe joints carefully until cement sets.

14. Horizontal portions of the venting system shall be

supported to prevent sagging. Support any piping at a

minimum of every 5 ft. using perforated metal hanging

strap or commercially available hangars designed to

support plastic pipe.

15. Prevent condensate from accumulating in the pipes

by sloping the combustion air piping and vent piping

downward toward furnace a minimum of 1/4” per linear

ft. with no sags between hangers.

16. Complete the vent installation by installing the required

termination. See figures 23 to 27 for allowed termination.

17. Use appropriate methods to seal the openings where

combustion air pipe and vent pipe pass through roof or

sidewall.

7.8

COMBUSTION AIR PIPE

CONNECTION

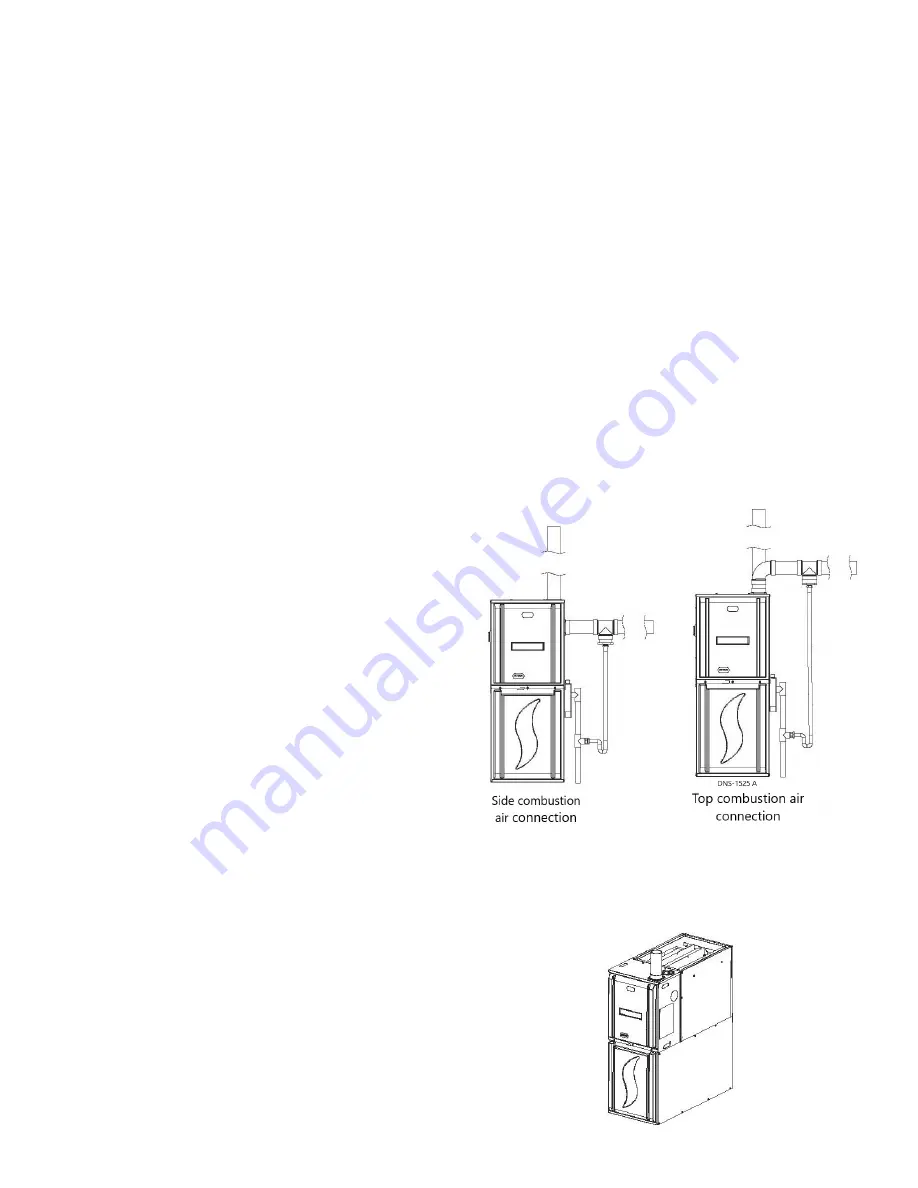

Chinook gas furnaces have three possible locations for the

combustion air connection : top panel, right side panel or left

side panel. Choose which configuration is best suited for your

application. See figures 19 and 20.

To connect the combustion air pipe, use the venting flange with

the gasket and screw it to the chosen location. Secure the

combustion air pipe to the flange using glue.

At the combustion air termination, use a 90° elbow or two

medium-radius sweep elbows to keep the inlet downward and

prevent the entry of rain. The inlet opening of the combustion

air termination must be a minimum of 12” above the anticipated

level of snow accumulation.

The furnace may have a drain tee assembly and trap installed

in the combustion air pipe as close to the furnace as possible

(see figure 18). This is to drain any water that may enter the

combustion air pipe, preventing entry in the furnace vestibule

area.

Note that with horizontal combustion air pipe there is a risk

of excessive moisture entering the combustion air pipe and

consequently, furnace cabinet. A moiture trap should be added

to the combustion air pipe as shown in figure 18.

Figure 18 – Combustion air moisture trap

Figure 19 – Top panel combustion air

20

Содержание C105-2-V

Страница 24: ...Figure 29 Direct vent clearance 23 ...

Страница 25: ...Figure 30 Other than Direct vent clearance 24 ...

Страница 32: ...Figure 31 Dimensions 31 ...

Страница 33: ...Figure 32 Two Stage ECM Wiring diagram 32 ...

Страница 36: ...Figure 33 Exploded view Cxx 2 V part 1 35 ...

Страница 37: ...Figure 34 Exploded view Cxx 2 V part 2 36 ...