SERIES 60 ENGINE OPERATOR'S GUIDE

Glycol-based Coolants

Formulated For HVAC —

These coolants formulated for

Heating/Ventilation/Air Conditioning

(HVAC) should not be used. These

coolants generally contain high levels

of phosphates, which can deposit

on hot internal engine surfaces and

reduce heat transfer.

Additives Not Recommended

The following additives are not

recommended for use in Series 60

engines.

Soluble Oil Additives —

These

additives are not approved for use in

Detroit Diesel engine cooling systems.

A small amount of oil adversely

affects heat transfer. For example, a

1.25% concentration of soluble oil

increases fire deck temperature 6%.

A 2.50% concentration increases fire

deck temperature 15%. The use of

soluble oil additives may result in

engine overheating and/or failure.

Chromate Additives —

These

additives are not approved for use

in Detroit Diesel engine cooling

systems. Chromate additives can

form chromium hydroxide, commonly

called “green slime.” This, in turn,

can result in engine damage due to

poor heat transfer. Cooling systems

operated with chromium-inhibited

coolant must be chemically cleaned

with Power Cool dry chemical

cooling system cleaner/conditioner

listed in Table 46 (or equivalent

sulfamic acid/sodium carbonate

cleaner) and flushed.

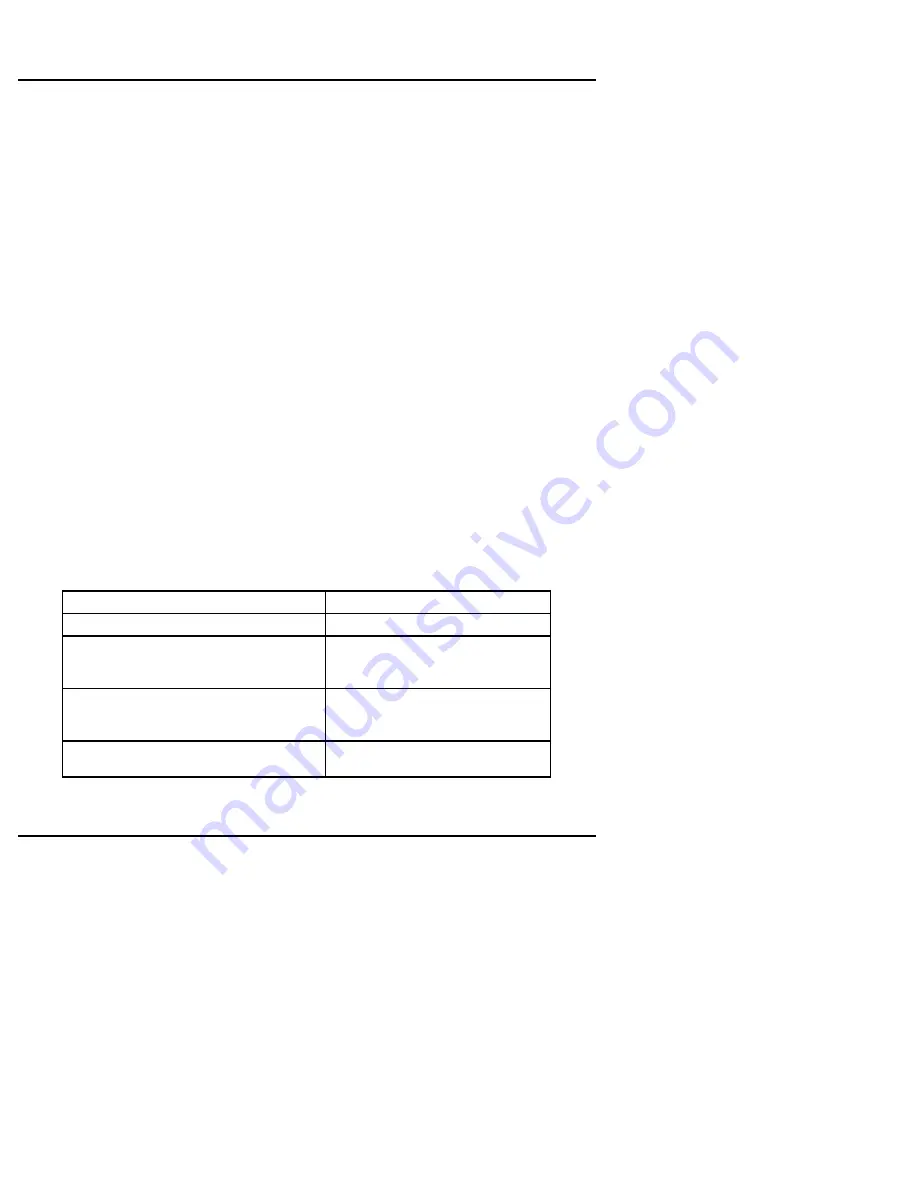

Coolant Inhibitor Test Intervals

The coolant inhibitor level should

be checked at the intervals

listed in Table 25.

Service Application

Inhibitor Test Interval

On-Highway Trucks and Motor Coaches

20,000 Miles (32,000 Kilometers)

City Transit Coaches, Pick-Up and

Delivery, Short Trip, and Emergency

Vehicles

6,000 Miles (9,600 Kilometers) or 3

Months, whichever comes first

Industrial, Continuous– Duty Generator

Set and All Other Applications, except

Standby Generator Set

500 Hours or 3 Months, whichever

comes first

Stand-By Generator Set

200 Hours or Yearly, whichever

comes first

Table 25

Required Coolant Inhibitor Test Intervals

All information subject to change without notice. (Rev. 01/04)

101

6SE484

0401

Copyright © 2004 DETROIT DIESEL CORPORATION