/Kits/1296-144CK.doc

6

8/15/2011

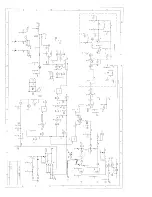

The hardware should be sorted and identified. There are some extras. But remember, No

substitutions or you are on your own!! Review the schematic and the component placement

diagram. Read through all of the assembly steps 1 - 13. Identify every component used. This will

ensure that you have the correct tools and supplies required to complete the transverter. It is also

time to make the last minute decision on building the kit or not. A full exchange towards a

assembled version will be provided if you do not go past this step. We want you to be on the band

and operating not struggling to assemble this because you were not aware of the effort and

techniques required takes to assemble this transverter!

At this time you may want to mark the component placement diagram with the associated

component values by the designators. Simply transpose the component list values to the

component placement document. We do not do this because the values will change over time

depending on availability, engineering changes, or obsolesces. The component list is easier to

update and maintain providing all users the latest improvements or changes to the design.

Updates to the design will be maintained on the DEMI web site in the future. Now! Start the

assembly!

1. Install all bottom side components of the PCB. K1-K3, Q1, and Q2. Do not solder the

cans of Q1 and Q2. All 5 filters are already installed and adjusted!

2. Install all active surface mount active components, Q3, IC1- IC3, IC5- IC7, and IC10 on

the top side of the circuit board per the top side component placement diagram. Do not install IC4,

VR1-VR4, or D1-D9

3. Install all surface mount capacitors and resistors and L31 per the topside component

placement diagram. Review the assembly tips if necessary pertaining to multiple components

sharing the same pad. Be sure of the placement of C57and C59. They are dependent of the

configuration of the transverter you require. Common antenna port (C57 and C59) or split transmit

and receive (C57A and C59A).

4. Wind inductors L1, L3, L9 and L10 as specified in the Bag 3 parts list. Then install all

inductors L1-L31. L5 or L5A placement is dependent on the placement of C59. The molded

chokes L2, and L30 should be surface mounted. L12 is optional and should be installed if you wish

to activate the PTT circuit through your Transceiver’s IF cable.

5. Now install all left over leaded components, pots, resistors, capacitors, diodes, Q4 and

regulators.

Do not install IC4, IC9, Y1, SW1, PTC1, R22, C72, or the LED’s. Do a surface mount

installation of C49, VR3, VR4, R25, R24, R10, R18, D2, D3, D8, and D9. When soldering the

leaded surface mount components, do not allow solder to leak through the ground plane of the

PCB. It will pool up and interfere with the pallet assembly. If you have a question, place the PCB

on the pallet to check.

6. Install the crystal as shown in Figure 6. Do not install the PTC1. It will occur later in the

assembly instruction after testing. The top side component placement shows the crystal standing

up but lay it down over L2 as shown in this pictorial. Again, do not install the PTC.

CRYSTAL

Solder Wire to

Ground and Xtal

9Volt Supply

Xtal leads

~ 1/8” Space between

PC Board and Xtal

Figure 6. Crystal and PTC-60 installation detail.

Содержание 1296-144 CK

Страница 16: ......