Page 19

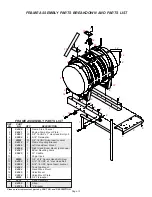

DIAPHRAGM PUMP PLUMBING PARTS LIST

REF.

PART

NO.

NO.

QTY

DESCRIPTION

NOTE: Contact local authorized Briggs and Stratton dealer for replacement gas engines and parts.

Need model no. and type no. of engine to order parts from your Briggs and Stratton dealer.

REF.

PART

NO.

NO.

QTY

DESCRIPTION

1.

P55 23A

1

55 gallon Tank (incl. lid, agitation and

outlet fittings).

2.

PL5A

1

5î cover for tank

3.

5044 -1

1

Single Agitation Wand Assembly

4.

M1200

1

1/2" MPT Short Nipple

5.

EL1238

1

1/2" MPT x 3/8" Hose Barb Elbow

6.

580RB

-

5/8" I.D Rubber Hose

7.

UV075FP

3

3/4" Poly Ball Valve

8.

A3438

3

3/4" MPT x 3/8" Hose Barb

9.

B6H

10

3/8" Hose Clamp

10.

380RB

-

3/8" I.D Rubber Hose

11.

EL114 34

1

1-1/4" MPT x 3/4" Hose Barb Elbow

12.

BEL3434

3

3/4" MPT x 3/4" Hose Barb Elbow

13.

B12H

4

3/4" Hose Clamp

14.

340RB

-

3/4" I.D Rubber Hose

15.

BM3400

4

3/4" Short Nipple

-

RVF34 80

-

3/4" Line Strainer w/80 mesh screen

16.

RVF34C

1

3/4" Strainer Cup

17.

RVF34GV

1

Viton O-ring for 3/4" Strainer

18.

RVF380

1

80 Mesh Screen for 3/4" Strainer

19.

RVF34B

1

Strainer Bowl

20.

BTT34

2

3/4" FPT Tee

OPERATION INSTRUCTIONS

1.

Be sure oil is halfway up the clear oil sight tube. If

necessary, fill to correct level with 30 weight non-

detergent motor oil.

2.

Make sure the suction hose barb is tightly screwed onto

the suction union, and that there are no air leaks on the

inlet side of the pump.

3.

Check the charge pressure on the pulsation damper

before starting the pump. The pressure is checked with

a standard automotive air gauge. The pressure should

be at approximately 20% of the maximum operating

pressure with a minimum charge of 10 PSI.

4.

Allow the pump to start under low pressure by removing

restrictions on the outlet of the pump. The restriction on

the pump is removed by rotating the red knob on the

control unit so that the letter A on the knob is in the 12

o'clock position.

5.

Start pump and let run for approximately one minute at

low pressure. Stop pump and check the oil level in sight

glass. Add 30 weight non-detergent oil if necessary.

6.

Adjust pump to desired pressure by changing the relief

valve setting on the control unit, relief valve or unloader.

First back out relief valve adjustment knob to zero. Then

rotate red bypass selector knob so that the letter C is in

the 12 o'clock position. Adjust pressure by rotating relief

valve adjustment knob to desired pressure.

1.

After use, flush pump with clean water.

2.

Change oil and diaphragms every 500 hours. To drain

oil from the pump, remove cap from oil sight tube, turn

pump upside down and rotate the shaft until oil stops

flowing out. To fill pump with oil, slowly pour oil into sight

tube while turning the pump shaft. Turning the pump

shaft purges all the air out of the crankcase. Always

change oil when replacing diaphragms.

3.

For winter storage or if a freezing condition will be

encountered, flush pump with a 50/50 mixture of water

and antifreeze.

MAINTENANCE INSTRUCTIONS

Please order replacement parts by PART NO. and DESCRIPTION.

21.

A3458

1

3/4" MPT x 5/8" Hose Barb

22.

9910D19GRG

I

1

Diaphragm Pump w/Gear Reducer

23.

GE3HP

1

3.5 HP Gas Engine (Horizontal Shaft)

-

GH4HP

1

4 HP Gas Engine (Horizontal Shaft)

24.

00372

4

5/16"-18 UNC x 1-1/2" Hex Head Bolt

25.

02802

5

5/16"-18 UNC Nylon Insert Locknut

26.

05596

1

Tee Mount Bracket

27.

02772

4

1/4"-20 UNC Nylon Insert Locknuts

28.

6B1

1

Direct - o - Valve

29.

160GBF

1

160 lb. Brass Pressure Gauge

30.

04055

4

1/4"-20 UNC x 1" Hex Head Bolt

31.

00214

4

1/4" Flatwasher

32.

A1238

1

1/2" MPT x 3/8" Hose Barb Reducer

33.

EL3438

1

3/4" MPT x 3/8" Hose Barb Elbow

34.

05034

1

6B1 Valve Mounting Plate

35.

F3400

1

3/4" MPT Plug

36.

A1438

1

1/4" MGHT x 3/8" Hose Barb

37.

30L22425 18

1

Spray Wand

38. 5500 18PP 1

Adjustable Tip (ordered separate)

39.

B24H

2

1-1/4" Hose Clamp

40.

02990

1

.313 NC x 1 GR5 Hex bolt

41.

02801

1

Nut .313 NC Lock, Nylon Insert