SV

Alarm Type

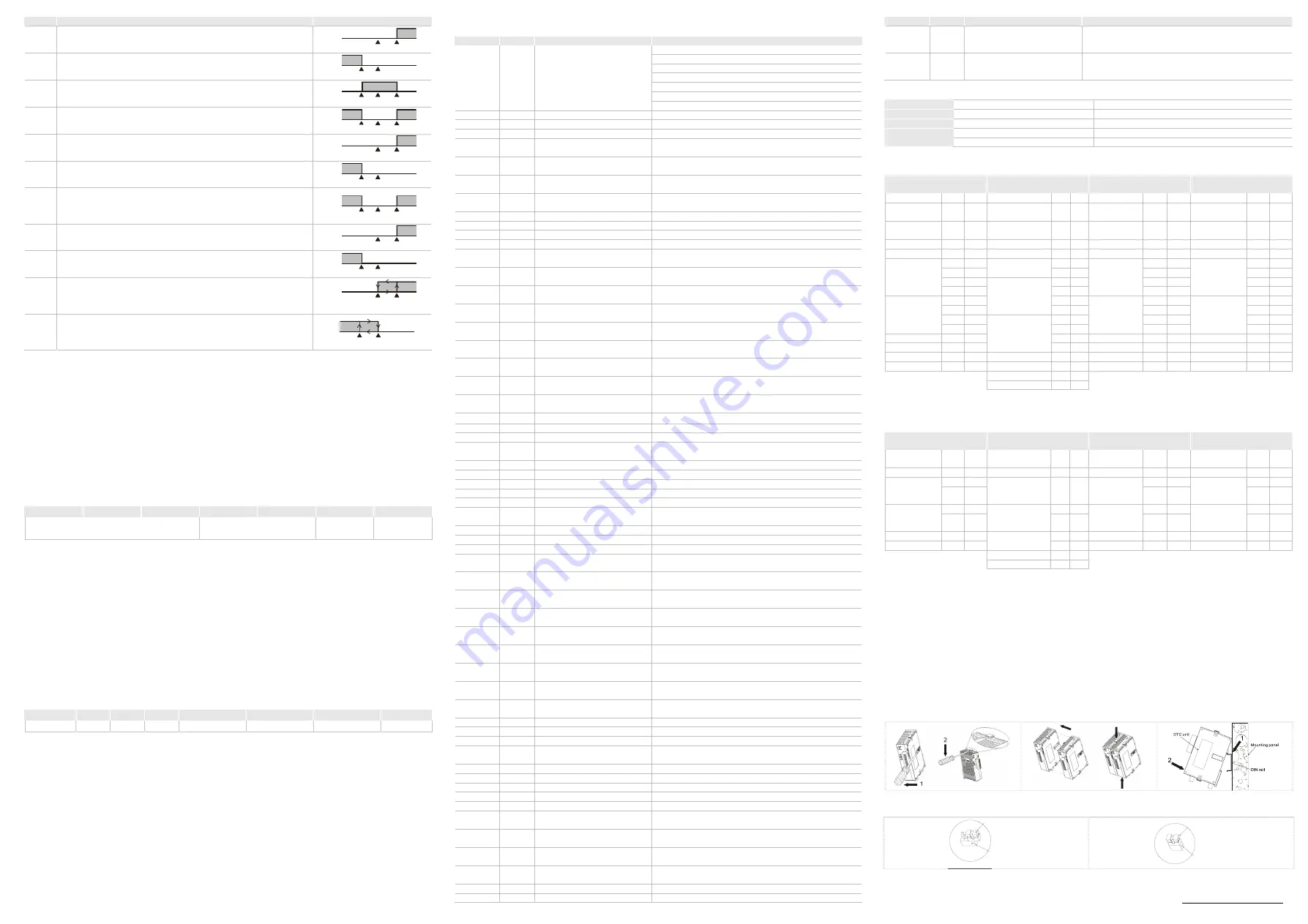

Alarm Output Function

2

Deviation upper-limit:

This alarm output operates when PV value is higher than the setting value

SV+ (AL-H).

ON

OFF

SV

AL-H

3

Deviation lower-limit:

This alarm output operates when PV value is lower than the setting value

SV- (AL-L).

ON

OFF

AL-L

SV

4

Reverse deviation upper- and lower-limit:

This alarm output operates when PV value is in the range of the setting

value SV+ (AL-H) and the setting value SV- (AL-L).

ON

OFF

AL-L

SV

AL-H

5

Absolute value upper- and lower-limit:

This alarm output operates when PV value is higher than the setting value

AL-H or lower than the setting value AL-L.

ON

OFF

AL-L

AL-H

6

Absolute value upper-limit:

This alarm output operates when PV value is higher than the setting value

AL-H.

ON

OFF

AL-H

7

Absolute value lower-limit:

This alarm output operates when PV value is lower than the setting value

AL-L.

ON

OFF

AL-L

8

Deviation upper- and lower-limit with standby sequence:

This alarm output operates when PV value reaches set point (SV value)

and the value is higher than the setting value SV+(AL-H) or lower than the

setting value SV- (AL-L).

ON

OFF

AL-L

AL-H

SV

9

Deviation upper-limit with standby sequence:

This alarm output operates when PV value reaches set point (SV value)

and the reached value is higher than the setting value SV+ (AL-H).

ON

OFF

SV

AL-H

10

Deviation lower-limit with standby sequence:

This alarm output operates when PV value reaches the set point (SV

value) and the reached value is lower than the setting value SV- (AL-L).

ON

OFF

AL-L SV

11

Hysteresis upper-limit alarm output:

This alarm output operates if PV value is higher than the setting value

SV+ (AL-H). This alarm output is OFF when PV value is lower than the

setting value SV+ (AL-L).

ON

OFF

AL-H

AL-L

12

Hysteresis lower-limit alarm output:

This alarm output operates if PV value is lower than the setting value SV-

(AL-H). This alarm output is OFF when PV value is higher than the setting

value SV- (AL-L).

ON

OFF

AL-H

AL-L

Attention: AL-H and AL-L include AL1H, AL2H and AL1L, AL2L. When the 1

st

group output is set to alarm output, AL1H (1024H) and AL1L (1025H)

will be used. When the 2

nd

group output is set to alarm output, AL2H (1026H) and AL2L (1027H) will be used.

LED Display

1. When power is normal, POWER LED will be lit.

2. LED will be lit after power on. Within one second after power on, communication protocol will be displayed; and at

the following second after communication protocol displayed, communication address will be displayed. After that,

LED will all be lit to show operation is normal.

3. When control action is executing, RUN LED will be lit.

4. When input, memory, or communication happens to error, ERROR LED will be lit.

5. When output is acted, the corresponding LED will be lit.

6. When PID program is auto adjusting parameter, AT LED will blink.

7. RX LED will blink when receiving communication signal and TX LED will blink when transmitting communication

signal.

Protocol Format of LED Display When Power On

AT

TX

RX

O1

O2

Err

Run

000: 2,400bps 001: 4,800bps 010: 9,600bps

011: 19,200bps 100: 38,400bps

Parity 00: None 01: Even

10: Odd

0: ASCII

1: RTU

0:2 Stop bit

1:1 Stop bit

Communication address display: AT (bit 6) and Run (bit 0) will combine to binary code.

Password Function

The default of password will not operate. After writing 4-byte password into specific communication address, password

function will be activated. There are three levels for password protection:

1. Level1: only LED status, settings, and input values can be read via communication. It is unable to revise anything.

2. Level2: only LED status, settings, and input value can be read via communication. Also, it is able to revise setting.

3. Level3: all the settings can be read via communication, but it is only revisable for settings and AT adjustment.

4. No password function.

Once password is set (106EH ~ 1070H), the controller will enter level 1. For entering another level, please key in

corresponding password in 106BH ~ 106DH (see Address and content of Data Register). After power off, it will get back

to level one. If password protection function shall be dismissed, it is necessary to clear all password setting.

To enable password function, it is necessary to write corresponding password (106EH ~ 1070H) when password status

is dismissed. To dismiss password levels, intended password setting should be written in specific function address

106EH ~ 1070H.

Password status can be read from 106EH~1070H. Statuses corresponding to each bit are shown as the following table:

Bit

b0

b1

b2

b3

b4

b5

b6

Status Level

1 Level 2 Level 3

Level 1 locked

Level 2 locked

Level 3 locked

Unlock

Bit = 0 means no password setting. Bit = 1 means password is set (b0 ~ b2). b3 ~ b6 are used for displaying current

password status.

Synchronous Communication Protocol & Auto Number ID

By using Auto Number ID function, the communication protocol of DTC2000 can be set the same as the one of

DTC1000. ID numbers tend to increase.

1. Set the auto communication flag to be “1” for DTC1000 (communication address 1022H).

2. Switch off the controller before connecting to another DTC2000. After that, switch on the power again.

3. Communication default: 9600bps, 7bits, Even, 1 stop bit.

4. This function will result in additional 3~5 seconds for power on.

RS-485 Communication

1. Supporting transmission speed: 2,400, 4,800, 9,600, 19,200, 38,400bps.

2. Non-supported formats: 7, N, 1 or 8, E, 2 or 8, O, 2.

3. Communication protocol: Modbus (ASCII or RTU)

4. Function code: 03H to read the content of register (max. 8 words). 06H to write one word into register. 01H to read

bits data (max. 16 bits). 05H to write one bit to register.

5. Address and Content of Data Register:

Address

Setting

Content

Explanation

Temperature unit: 0.1 degree. Analog input: 1EU.

Following read values happen to errors:

8002H: Initial process (Temperature value is not got yet)

8003H: Temperature sensor is not connected

8004H: Temperature sensor input error

8006H: Cannot get temperature value, ADC input error

1000H Process

value

(PV)

8007H: Memory read/write error

1001H

0

Set point (SV)

Unit: 0.1 degree. Analog input: 1EU.

1002H

6,000

Upper-limit of temperature range Upper-limit ban, unit: 0.1 degree.

1003H

-200

Lower-limit of temperature range Lower-limit ban, unit: 0.1 degree.

1004H

12

Input temperature sensor type

Please refer to the contents of the “Temperature Sensor

Type and Temperature Range” for detail

1005H 0 Control

method

0: PID, 1: ON/OFF, 2: manual tuning, 3: PID program

control

1007H 4

1st group of Heating/Cooling

control cycle

0 ~ 99, 0: 0.5sec

1008H 4

2nd group of Heating/Cooling

control cycle

0 ~ 99, 0:0.5sec (it will be invalid when both groups are

control output at the same time)

1009H

476

PB Proportional band

1 ~ 9,999, unit: 0.1 degree, analog input: 1EU

100AH

260

Ti Integral time

0 ~ 9,999

100BH

41

Td Derivative time

0 ~ 9,999

100CH

0

Integration default

0 ~ 1,000, unit: 0.1%

100DH 0

Proportional control offset

error value, when Ti = 0

0 ~ 1,000, unit: 0.1%

100EH 100

COEF setting when Dual

Loop output control are used

1 ~ 9,999, unit: 0.01

100FH 0

Dead band setting when Dual

Loop output control are used

-999 ~ 9,999, unit: 0.1 degree or 1EU

1010H 0

Hysteresis setting value of the

1st output group

0 ~ 9,999, unit: 0.1 degree or 1EU

1011H 0

Hysteresis setting value of the

2nd output group

0 ~ 9,999, unit: 0.1 degree or 1EU

1012H 0

Output value read and write of

Output 1

Unit: 0.1%, write is valid only under manual control mode

1013H 0

Output value read and write of

Output 2

Unit: 0.1%, write is valid only under manual control mode

1014H 0

Upper-limit regulation of analog

linear output

1 scale = 2.8

μ

A = 1.3mV

1015H 0

Lower-limit regulation of analog

linear output

1 scale = 2.8

μ

A = 1.3mV

1016H

0

Temperature regulation value

-999 ~

+

999, unit: 0.1 degree or 1EU

1020H

0

Alarm 1 type

Please see the contents of the “Alarm Outputs” for detail

1021H

0

Alarm 2 type

Please see the contents of the “Alarm Outputs” for detail

1022H 0

Auto-setting communication

flag

Auto setting ban of communication: 0, auto setting of

communication: 1

1024H

40

Upper-limit alarm 1 AL1H

Please see the contents of the “Alarm Outputs” for detail

1025H

40

Lower-limit alarm 1 AL1L

Please see the contents of the “Alarm Outputs” for detail

1026H

40

Upper-limit alarm 2 AL2H

Please see the contents of the “Alarm Outputs” for detail

1027H

40

Lower-limit alarm 2 AL2L

Please see the contents of the “Alarm Outputs” for detail

102AH Read/Write

status

b1:

ALM2,

b2:

o

C, b3:

o

F, b4: ALM1, b5: O2, b6:O1, b7: AT

102CH 0

Setting of positive/negative

proportional output

0: positive, 1: negative

102EH

LED status

b0: RUN, b1: ERR, b2: O2, b3: O1, b4: RX, b5:TX b6: AT

102FH

Software version

V1.00 indicates 0x100

1030H

0

Start pattern number

0 ~ 7

1032H

Remaining time of read

execution

Unit: second

1033H

Remaining time of reading

execution step

Unit: minute

1034H

Step number of reading

current execution step

0 ~ 7

1035H

Executing number of reading

current pattern

0 ~ 7

1037H 1,000

Upper-limit of proportional

output

0 ~ 100% max. analog output is upper limit, unit: 0.1%

1038H 0

Lower-limit of proportional

output

0 ~ 100% max. analog output is lower limit, unit: 0.1%

1040H~

1043H

7

Actual step number setting

inside the correspond pattern

0 ~ 7 = N means the pattern is executed from step from 0

to N.

1050H~

1053H

0

Cycle number of repeating

executing pattern 0 ~ 7

0 ~ 199 means the pattern is executed for 1 ~ 200 times.

1060H~

1063H

0

Link pattern number setting of

the current pattern

0 ~ 8, 8 means program end. 0 ~ 7 means the next

execution number after completing current pattern.

1068H

1

Control execution/Stop setting

0: Stop, 1: execute, 2: program end, 3: program hold

1069H

0

Output 1: control selection

0: heating, 1: cooling, 2: alarming, 3: proportional output

106AH

0

Output2: control selection

0: heating, 1: cooling, 2: alarming

106BH 0

Dismiss level 1

Read/write allowed

Shall be same as level 1 password setting (106E)

106CH

0

Dismiss level 2. Use level 3.

Shall be same as level 2 password setting (106F)

106DH

0

Dismiss level 3. Use level 2

Shall be same as level 3 password setting (1070)

106EH

0

Dismiss level 1/Set password

Clear old password before new password setting

106FH

0

Dismiss level 2/Set password

Clear old password before new password setting

1070H

0

Dismiss level 3/Set password

Clear old password before new password setting

1071H 1

Read/Write communication

address

1 ~ 247

1072H 0

Read/Write communication

format

RTU: 1, ASCII: 0

1073H 2

Baud rate setting of

communication

0 ~ 4: 2,400 ~ 38,400

1074H 1

Data length setting of

communication

0: 8bit 1: 7bit

1075H

1

Parity bit setting

0: None 1:Even 2: Odd

1076H

1

Stop bit setting

0: 2 stop bit 1: 1stop bit

Address

Setting

Content

Explanation

2000H~

203FH

0

Pattern 0 ~ 7 to set target

temperature

Pattern 0: 2000H ~ 2007H

Temperature measure unit: 0.1 degree

2080H~

20BFH

0

Pattern 0~7 to set execution

time.

Pattern 0: 2080H ~ 2087H

Time 0 ~ 900 (1 minute for each scale)

6. Address and Content of Bit Register: ( First bit of reading will put into LSB, Write data = FF00H for bit set, 0000H

for bit data as “0”)

0811H

Temperature unit display selection

0:

o

F, 1:

o

C (default)

0813H

AT setting

AT setting OFF: 0 (default), AT setting ON: 1

0814H

Control RUN/STOP setting

0: STOP, 1: Execute (default)

0815H

Program hold flag

1: Program temporary stop

0816H

Program stop flag

1: Program stop

7. Communication format: 01: read bit data, 05: write bit data, 03: read word, 06: write word.

ASCII Mode:

To Read Instruction

To Read Response

Message

To Write Instruction

To Write Response

Message

Starting word

’

:

’

’

:

’

Starting word

’

:

’ ’

:

’ Starting word ’

:

’

’

:

’

Starting word

’

:

’

’

:

’

Machine

address 1

‘0’

‘0’ Machine address

1

‘0’

‘0’

Machine

address 1

‘0’

‘0’

Machine

address 1

‘0’

‘0’

Machine

address 0

‘1’

‘1’ Machine address

0

‘1’

‘1’

Machine

address 0

‘1’

‘1’

Machine

address 0

‘1’

‘1’

Instruction 1

‘0’

‘0’

Instruction 1

‘0’

‘0’

Instruction 1

‘0’

‘0’

Instruction 1

‘0’

‘0’

Instruction 0

‘3’

‘1’

Instruction 0

‘3’

‘1’

Instruction 0

‘6’

‘5’

Instruction 0

‘6’

‘5’

‘1’

‘0’

‘0’

‘0’

‘1’

‘0’

‘1’

‘0’

‘0’

‘8’

Response data

length (byte)

‘4’

‘2’

‘0’

‘8’

‘0’

‘8’

‘0’

‘1’

‘0’

‘1’

‘0’

‘1’

‘0’

‘1’

To read

data/Staring

word address

‘0’

‘0’

‘1’

‘7’

To write data

address

‘1’

‘0’

To write data

address

‘1’

‘0’

‘0’

‘0’

‘F’

‘0’

‘0’

‘F’

‘0’

‘F’

‘0’

‘0’

Data content of

1000H/081xH

‘4’

‘1’

‘3’

‘F’

‘3’

‘F’

‘0’

‘0’

‘0’

‘E’

‘0’

‘E’

‘0’

To read data

length/Word

length

(word/bit)

‘2’

‘9’

‘0’

To write data

content

‘8’

‘0’

To write data

content

‘8’

‘0’

LRC1 check ‘E’

‘D’

‘0’

LRC1

‘F’

‘E’

LRC1

‘F’

‘E’

LRC 0 check

‘A’

‘D’

Data content of

1001H

‘0’

LRC

0

‘D’

‘3’

LRC 0

‘D’

‘3’

Ending word 1 CR

CR

LRC1 check

‘0’ ‘E’ Ending word 1 CR

CR Ending word 1 CR

CR

Ending word 0 LF

LF

LRC 0 check

‘3’

‘4’ Ending word 0 LF

LF

Ending word 0 LF

LF

Ending word 1

CR CR

Ending word 0

LF LF

LRC Check:

LRC check is the added sum from “Machine Address” to “Data content”. For example, 01H + 03H + 10H+ 00H + 00H + 02H

= 16H, then take the complementary of 2 to get EA.

RTU Mode:

To Read Instruction

To Read Response

Message

To Write Instruction

To Write Response

Message

Machine

address

01H 01H

Machine address

01H 01H

Machine

address

01H 01H

Machine

address

01H 01H

Instruction 03H 01H

Instruction 03H 01H

Instruction 06H 05H

Instruction 06H 05H

10H 08H

10H 08H

10H 08H

Starting

address of

reading data

00H 10H

Response data

length (byte)

04H 02H

To write data

address

01H 10H

To write data

address

01H 10H

00H 00H

01H 17H

03H FFH

03H FFH

To read data

length

(word/bit)

02H 09H

Data content 1 F4H 01H

To write data

content

20H 00H

To write data

content

20H 00H

CRC low byte C0H BBH

03H

CRC low byte DDH 8FH CRC low byte DDH 8FH

CRC high byte CBH A9H

Data content 2

20H

CRC

high

byte E2H 9FH CRC high byte E2H 9FH

CRC low byte BBH 77H

CRC

high

byte 15H 88H

Following is a CRC (Cyclical Redundancy Check) program example:

unsigned int reg_crc = 0xffff; i = 0;

while (length--)

{

reg_crc ^= RTUData[i];

i ++;

for (j = 0; j < 8; j++)

{

if (reg_crc & 0x01)

reg_crc = (reg_crc >> 1) ^ 0xA001;

else

reg_crc = reg_crc >> 1;

}

}

return(reg_crc);

Installation

DTC modules can be expanded up to 8, and installed with DIN rail mounting

How to Set Up Current Input

For normal input

For current input (4 ~ 20mA, 0 ~ 20mA)

JU MPER

PIN HEADER

JP1

DEFAU LT SETTING

J UMPER

PIN HEADER

JP1

The content of this instruction sheet may be revised without prior notice. Please consult our distributors or download the most

updated version at http://www.delta.com.tw/industrialautomation