14

15

12

11

2

3

4

5

6

1

10

9

13

8

7

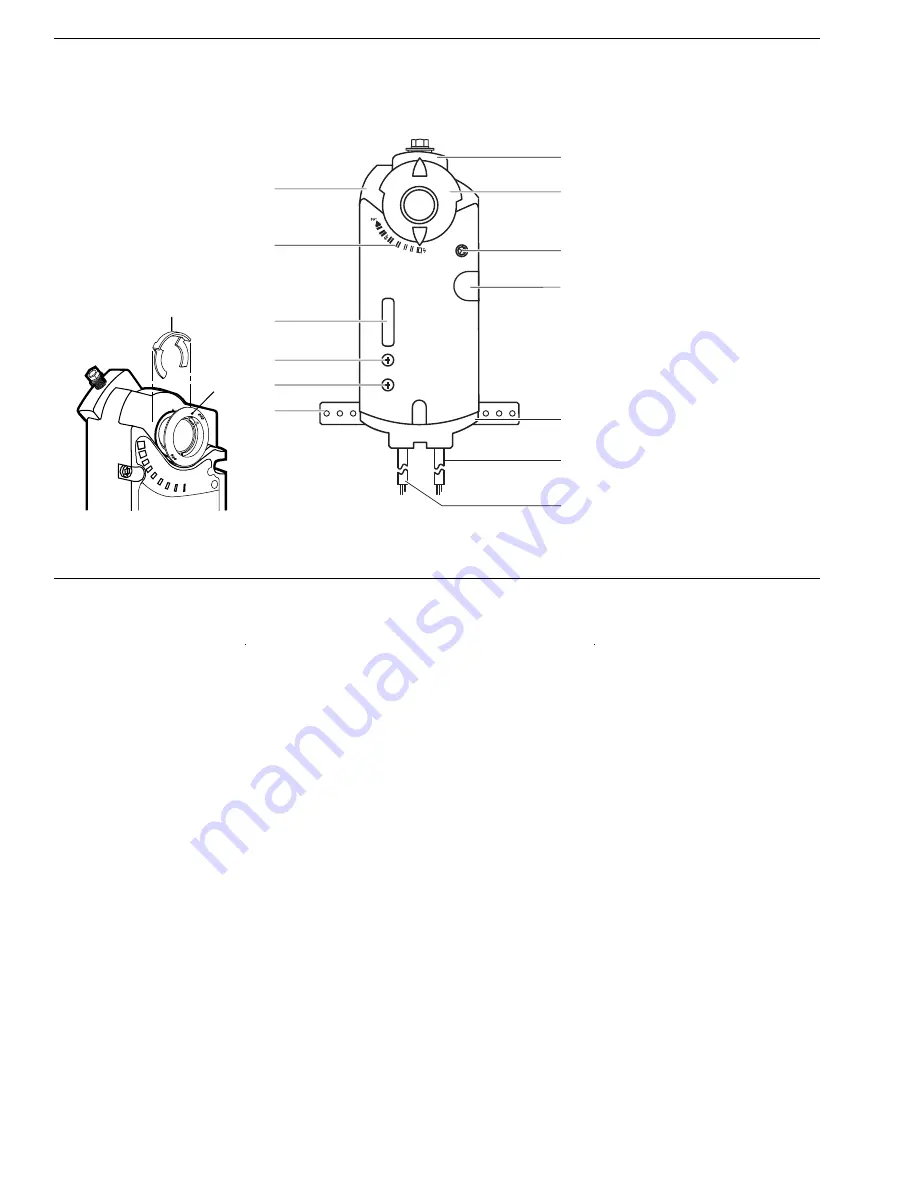

Legend

1. Actuator housing

2. Positioning scale for angle of

rotation

3. DIP switches and cover

4. Span adjustment

5. Offset (start point) adjustment

6. Mounting bracket

7. Connection cable for power

and control signals

8. Connection cable for auxiliary

switches or feedback potentiometer

9. Manual override

10. Auxiliary switches A & B

11. Position indicator

12. Self centering shaft adapter

13. 1/2-inch NSPT conduit

connection

14. Shaft adapter locking clip

15. Position indicator adapter

Figure 1. Non-Spring Return Actuator Components.

Actuator Components

Operation

DCM24-132 and DCM24-132-ZA

Apply a 0 to 10 Vdc control signal between wire 8 (Y) and wire 2 (G0) to operate the damper actuator. The angle of rotation

is proportional to the control signal. A 0 to 10 Vdc position feedback output signal is available between wire 9 (U) and

wire 2 (G0) to monitor the position of the damper motor. In the event of a power failure, the actuator holds its position. In

the event that only the control signal is lost, the actuator returns to the "0" position.

DC24-132-T,

DC24-132-TA

A floating control signal controls the damper actuator. The actuator’s angle of rotation is proportional to the length of

time the signal is applied. A 24 Vac control signal to wire 6 (Y1) causes the actuator coupling to rotate clockwise. A 24 Vac

control signal to wire 7 (Y2) causes the actuator coupling to rotate counterclockwise. To reverse the direction of rotation,

wires 6 (Y1) and 7 (Y2) can be interchanged. With no control voltage, the damper actuator holds its position.

Overload Protection

In the event of a blockage in the damper, the actuator is overload protected over the full rangeto prevent damage to the

actuator.

PAGE 3