12

OPERATIONS

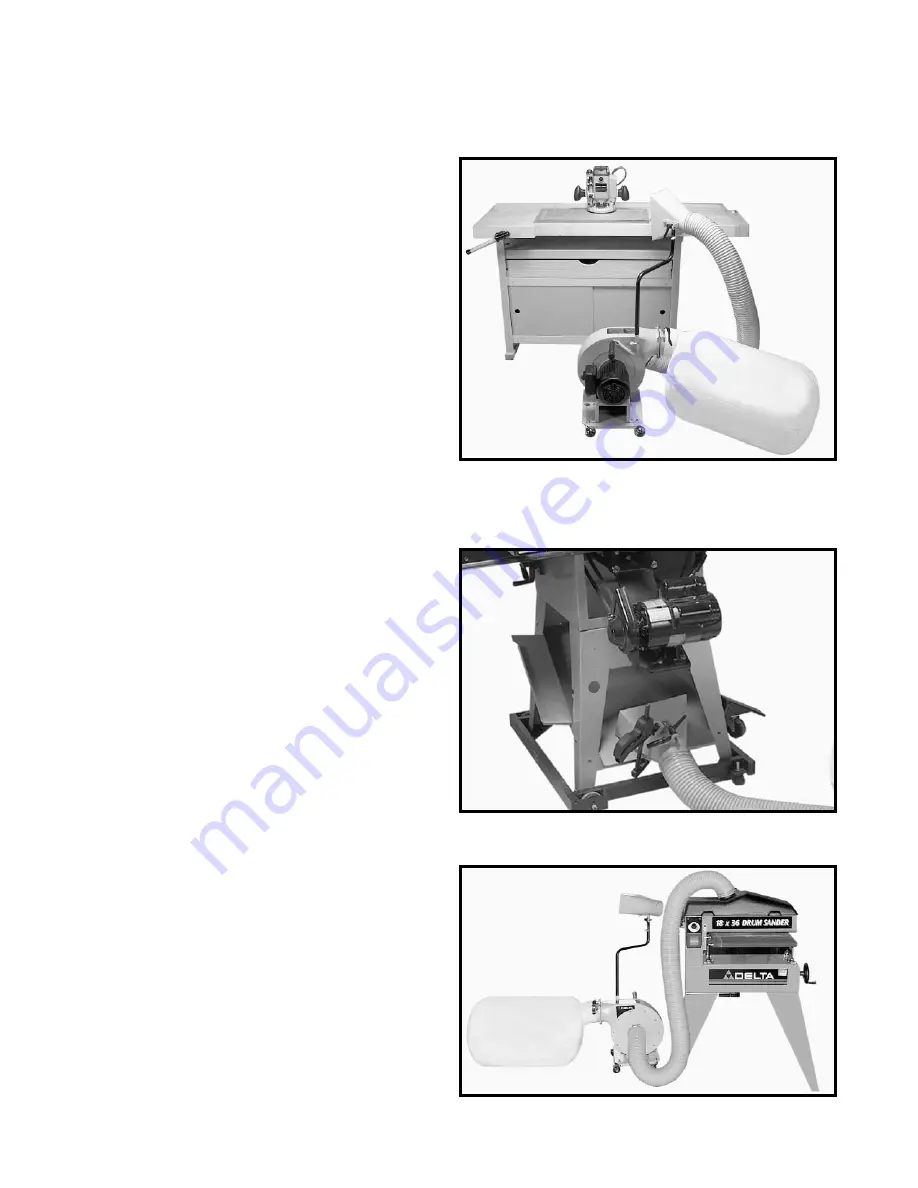

This versatile dust collector is light, compact and can

easily be transported to a variety of locations for use in

and out of the workshop. This dust collector can be

used with many different types of woodworking

machinery as shown in Figs. 26, 27, and 28. This dust

collector shows its versatility in the way that the intake

port can be positioned to accommodate different types

of wood working machinery.

Fig. 26 illustrates the dust collector used in conjunction

with a router. Note that the intake port is adjusted so that

it will be able to collect the dust created by using the

router.

Fig. 27 illustrates the dust collector used in conjunction

with a table saw. Note that the intake port is removed

from the lower tube support. The intake funnel can be

clamped to a tool to provide dust collection as shown.

Fig. 28 illustrates the dust collector used in conjunction

with a drum sander that is equipped with a dust removal

port. The intake funnel can be removed and the 4" dust

tube can be connected directly to the dust removal port.

Fig. 26

Fig. 27

Fig. 28