9

Fig. 22

Fig. 21

Fig. 20

Fig. 19

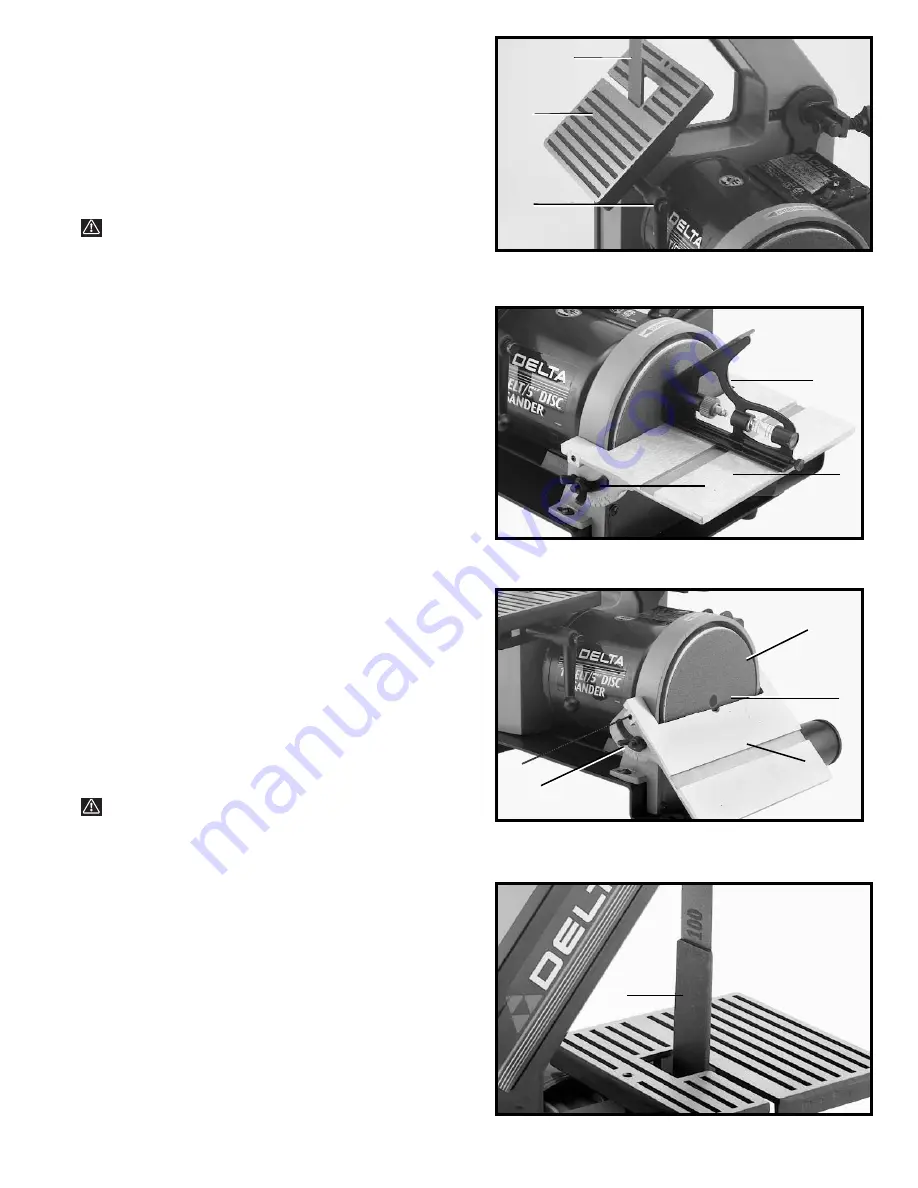

The disc table (C) can be tilted down 45 degrees (Fig.

21), by loosening the two wing nuts (one of which is

shown at (B) Fig. 21). Tilt the table to the desired angle

and tighten the two wing nuts.

NOTE

: The power take-off location is shown at (D) Fig.

21, and can be used with the table in the tilted down

position. The accessory flexible shaft can be attached at

this location (leaving the abrasive on the sanding disc)

by cutting a small hole in the center of the abrasive to

provide an entrance for the flexible shaft.

The disc table can be adjusted in or out to the disc by

loosening the two set screws (F) Fig. 21 (one of which is

shown), and adjusting table and retightening the two set

screws (F).

WARNING: To avoid trapping the workpiece or

your fingers between the table (C) and the sanding

disc (D), adjust the table so that it is a maximum

1/16" from disc, between the work table and the disc

(Fig. 21).

DISC TABLE ADJUSTMENTS

Check the table surface angle by placing a square (A)

Fig. 20 on the table with one end of the square against

the sanding disc. If angle is not 90 degrees, loosen the

two wing nuts (one of which is shown at (B) Fig. 20), and

move the table until the angle between the table and the

disc is 90 degrees. Tighten the two wing nuts.

4.

The table can be tilted to the front (Fig. 19), by

loosening table locking handle (C), tilting the table to

the desired angle and tightening the table locking

handle (C).

5.

The table can be adjusted in or out by loosening the

table locking handle and moving the table in or out.

Retighten lock handle when the adjustment has been

made.

WARNING: To avoid trapping the workpiece or

your fingers between the table (D) and the sanding

belt (E), adjust the table so that it is a maximum 1/16"

from belt, between the work table and the belt (see

the section “BELT TABLE ADJUSTMENTS”)

.

C

E

A

B

PLATEN

The platen (A) Fig. 22, is constructed of heavy steel to

properly support the work. To adjust, loosen the two

screws that fasten the bottom of the platen to the frame,

adjust the platen, so that it is almost touching the back

of the sanding belt, and tighten the two screws.

To remove the platen (A) Fig. 22, for strapping, polishing

or other special operations, remove the two screws that

fasten the bottom of the platen to the frame.

A

B

C

C

D

D

E

F