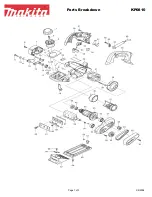

17

ADJUSTING CUTTINGHEAD

PARALLEL TO TABLE

The cuttinghead is set parallel to the table at the factory

and no further adjustment should be necessary. If your

machine is planing a taper, first check to see if the knives

are set properly in the cutterhead. Then check to see if

the cuttinghead is set parallel to the table as follows:

DISCONNECT MACHINE FROM POWER

SOURCE

.

1.

Place gage block (A) Fig. 49, on table directly under

front edge of head casting (B) as shown. Lower head

casting until front edge of head casting (B) just touches

the top of the gage block.

2.

Move gage block (A) Fig. 50, to opposite end of

table, as shown. Distance from table to edge of head

casting should be the same.

3.

Repeat

STEPS 2

and

3

on outfeed end of table.

4.

If head casting is not parallel to table, tilt planer on

its side as shown in Fig. 51. Remove bolt (C) and loosen

bolt (D) Fig. 51, which will allow you to move the idler

sprocket assembly (E) far enough to release tension on

chain as shown in Fig. 52. Remove chain from sprocket

on end of headcasting that must be adjusted. In this

case chain has been removed from sprocket (F).

5.

Turn sprocket (F) Fig. 52, by hand to bring that

corner into adjustment with the other three corners.

IM-

PORTANT: THIS ADJUSTMENT IS VERY SENSITIVE

AND IT SHOULD NOT BE NECESSARY TO TURN

THE SPROCKET MORE THAN ONE OR TWO TEETH

.

Turning sprocket (F) clockwise will decrease the

distance between the table and headcasting.

Counterclockwise will increase the distance.

6.

Replace chain being careful not to disturb the

position of the sprockets and replace idler sprocket

assembly (E) Fig. 51.

Fig. 49

Fig. 50

Fig. 51

Fig. 52

B

A

A

C

D

E

F