Check readings via the DL2 Control Panel

© 2006 Delta-T Devices Ltd

v1.1 Page 7

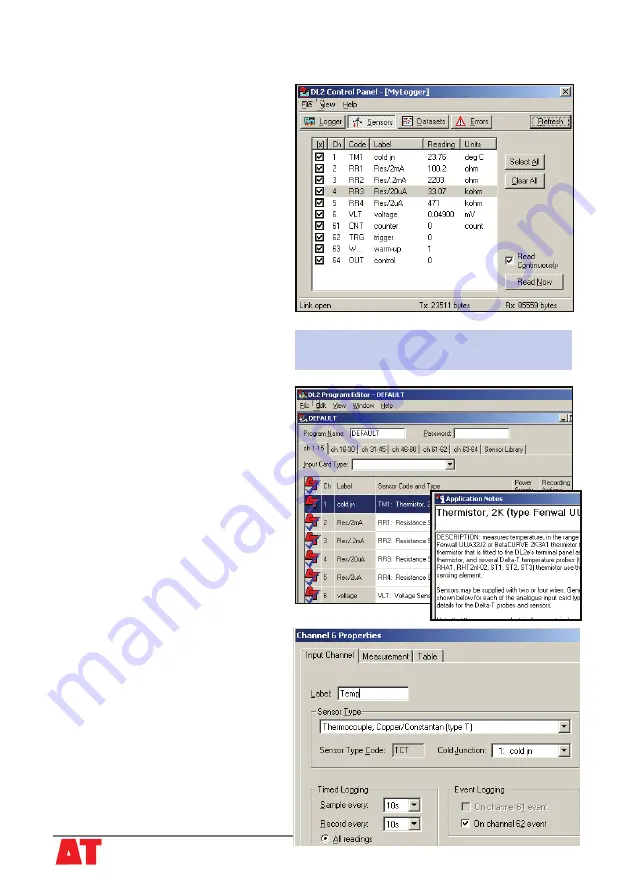

Sensors panel showing real-time readings from

the Tutorial Kit using DEFAULT logging

1. Wait until the logger sleeps before

you try to communicate via the PC.

2. Double click on the

My Logger

desktop icon to open the

DL2

Control Panel.

3. Click

Sensors

in the

DL2 Control

Panel.

4. Enable

Read Continuously

and

click

Select All,

and

Read Now.

5. Touch the thermocouple tip and

observe channel 6. The sensitivity is

~ 0.04 mV/°C temperature difference

between the thermocouple junction

and the cold junction.

Note: The resistors supplied are ±1%

so readings may differ a little from

the nominal values.

6) Reprogram the

Logger

1. On the

Logger

panel of the

DL2

Control Panel

click

Retrieve

to

upload a copy of the existing

DEFAULT

program in the logger.

An

Application Notes

box also

opens.

2. Examine the

ch 1-15

tab. Each

row represents a channel.

3. You have to tell the logger which

input card is connected to each

terminal group.

Select

LAC1, 15 channel

.

4. Double click on channel 6 to open

the

Sensor Type Properties

dialog.

5. From the

Sensor Type

drop

down list on the

Input Channels

tab,

select

Thermocouple: Copper

Constantan (type T)

.

6. Type in a new label of up to 8

characters e.g. “Temp”.

7. Select channel 1 for the

Cold

Junction Channel

.

(A cold junction is needed by all

thermocouples. A built-in thermistor

is provided on channel 1).