IT IS THE INSTALLER'S RESPONSIBILITY TO:

• ENSURE THAT THE RECESSED AREA IS WATERTIGHT TO PREVENT ANY WATER INGRESS.

• GUARD AGAINST THE ACCIDENTAL PRESENCE OF WATER IN THE RECESSED AREA AND ENSURE

THAT THERE IS NO WATER STAGNATION AND THAT ANY WATER (CONDENSATION, RUN-OFF,

LEAKAGE, ETC.) DRAINS AWAY.

• ENSURE THAT THE SEALS/JOINTS BETWEEN THE WALL PLATE AND THE BODY OF THE MIXER ARE

CHECKED REGULARLY (AT LEAST ONCE A YEAR) AND REPLACE THE SEALS/WASHERS IF NECESSARY.

Failure to comply with this advice may lead to leakage into the wall, for which Delabie

cannot be held responsible.

IF IN DOUBT, CONTACT TECHNICAL SUPPORT.

FOR

UK DOUGLAS DELABIE MARKET

ONLY: (01491) 824449;

FOR

ALL OTHER MARKETS

+33 (0)3-22-60-22-74.

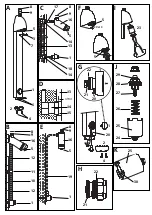

Ceiling-mounted SPORTING shower (fig. E)

• Connect the shower head

16

to the water supply.

• Mark, drill then fix the push-button starter

1

at a height of 1.10m from the floor using the screws

provided (use rawl plugs that are suitable for the wall type).

• Connect the push-button starter

1

and the shower head

16

using a 6/8 tube

19

.

• To ensure the shower operates correctly, restrict the length of the 6/8 connecting tube and the

number of elbows to a minimum (a maximum of 1 elbow).

• Install the supplied filter

8

to protect the non-return valve

9

and connect to the mixed water supply

at 37°C (recommended max. 41°C for the UK and Ireland). Ensure that all the connections are

waterproof.

GB

COMMISSIONING

• Press the push-button starter

1

several times (to evacuate any air from the pipes) until the

automatic shut-off delay is achieved (~30 sec. +5/-10): the first few operations may last 5 - 7

minutes.

Pressing on the push-button starter

1

, discharges a trickle of water and triggers the hydraulic timing

and the simultaneous opening of the valve. Once the push-button starter

1

is released, the trickle of

water will stop.

• The shower nozzle

5

can be adjusted by up to 20°

(fig. F)

, and locked in position using a pair of

circlip pliers.

REMEMBER

•

Our mixers/taps must be installed by professional installers

in accordance with current

regulations and recommendations in your country, and the specifications of the fluid engineer.

•

Sizing the pipes correctly

will avoid problems of pressure loss and unwanted noise. (See the

technical section in the brochure).

•

Protect the installation

with filters, water hammer absorbers and pressure reducers to reduce

the frequency of maintenance. (Recommended pressure: 0.8 - 5 bar).

• Install stopcocks

close to the mixer to facilitate maintenance.

• The pipework, stopcocks, mixers and all sanitary ware must be checked regularly, and at least once a year.