6

Detachable Parts

1.Oil cup installation: push the oil cup into the lower foot of the hood of the hood.

Dismantle: gently pull the oil cup along the horizontal direction, then it can be unloaded. Remove as

far as possible during the use of hood, and prevent excessive force when disassembling, so as not to

spill oil spills or cause accidents.

2.Press the protective cover from both sides to the middle, lift up and remove the protective cover.

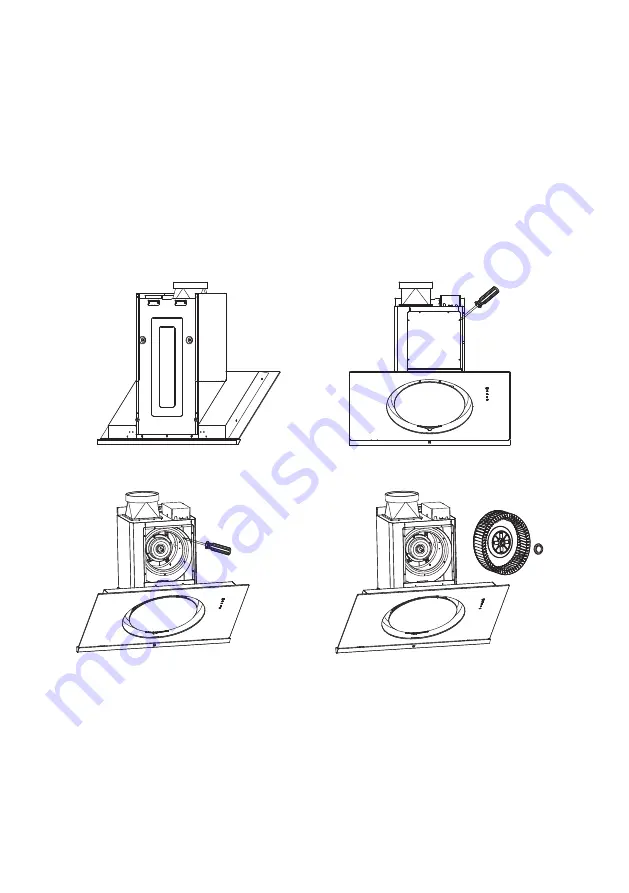

3. Case cover: screw the six screws of the fixed chassis cover with a cross screwdriver and lift it up.

4. Wind leaf

after unloading the chassis cover plate, screw the screw into the wind ring with the cross screwdriver

and remove the intake ring.

Clockwise unscrewing the blade cap and taking out the wind blade.

Содержание HA9055

Страница 8: ...7 ...