6

Do not use steel wool, abrasive cloths,

cleansers, or powders! If it is necessary to

scrape stainless steel to remove encrusted

materials, soak the area with hot cloths to

loosen the material, then use a wood or nylon

scraper. Do not use a metal knife, spatula, or

any other metal tool to scrape stainless steel!

Scratches are almost impossible to remove.

7. TROUBLESHOOTING

These troubleshooting procedures must be

carried out only by a Factory Authorized Service

Agent or a local service company specializing in

hotel and restaurant cooking appliances.

FACTORY APPROVAL MUST BE OBTAINED

PRIOR TO ANY WARRANTY WORK BEING

DONE OR DEAN INDUSTRIES CANNOT BE

HELD RESPONSIBLE.

7.1 If the elements will not turn on and there

is no evidence of heating the vessel even

when cold, check the following:

a) With the proper ON/OFF switch "ON",

manually reset the high temperature limit

switch (push the red button behind the

access door).

b) Check that the branch or main circuit

breakers or fuses are not tripped or

blown.

c) Check that correct line voltage exists

across block terminals L1-L2, L2-L3, and

L3-L1 (three-phase connection), or L1-

L2 (single-phase connection).

d) Check that correct line voltage exists on

all terminals on the load side of the

circuit breakers.

e) If the panel indicator light is glowing but

contactors are not actuated, check

continuity of the two holding coil circuits,

from the indicator light to L2.

f) If the panel indicator light is not glowing,

first check that line voltage does not

exist across the lamp, then:

1) Check the fuse for line voltage

between the load side and L2.

2) Check the power on/off switch for line

voltage between the load side and

L2.

3) Check the high limit thermostat for

line voltage between the load side

and L2; if resetting does not produce

results, replace the device.

4) Check the operating thermostat for

line voltage between the load side

and terminal L2; if defective, replace

the part.

5) Check the wiring to the temperature

controller.

7.2 Poor temperature control on the cold

side; warm-up time excessive; slow or

inadequate temperature recovery when

vessel loaded; uneven heating.

a) Check temperature controller

adjustment: Place the sensing bulb of a

high quality immersion thermometer

about 1-1/2 inches above the thermostat

sensing bulb or RTD probe and set the

controller dial for 350°F. Wait at least 20

minutes for the oil temperature to

stabilize. If the temperature is not with

+/-10°F of the dial setting, see "Probe

Test" below for the solid state

"Thermatron" controller or call for

service for an operating thermostat.

b) With the panel indicator light glowing,

check that both holding coil circuits or

contactors are energized and contactors

are actuated.

c) Check the load side of the contactors to

the heating element terminals. Each

element should draw about 30 amps

(208V) or 26 amps (240V).

Содержание 1414E

Страница 11: ...8 PARTS LIST COOL ZONE ELECTRIC FRYERS MODELS 714E 1414E 1818E 2020E ...

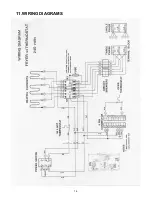

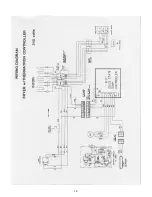

Страница 17: ...14 11 WIRING DIAGRAMS ...

Страница 18: ...15 ...

Страница 19: ...16 ...

Страница 20: ...17 ...