INTRODUCTION

UNIT OVERVIEW

The DC SOLUTIONS model MEGA-ARM barrier style parking gate operator is unique in the

industry. Setting the MEGA-ARM apart are many features that make it the front runner in its class.

With standard features like:

•

Built in battery backup - inherent 24 VDC backup power with regulated 24VDC for accessories.

•

High torque 24 volt Permanent Magnet DC motor .

•

Full service controller with eight inputs and LED indicators for loops, card reader, radio, etc...

•

Continuous duty operation for all applications (6k per day, SPRINT version 10k per day).

•

Reversible arm direction for right or left handed operation.

•

Instant Reverse Device

(IRD)

monitor senses obstructions going open and close.

•

Automatic open of gate arm when power is lost if desired (With 15 sec. delay selection).

•

Raise gate input memory will memorize multiple vehicles-ideal for barcode scanners & AVI.

•

Ability to have arm STOP in close travel if tail-gating is sensed at close loop.

•

Anti-tail gate alarm - fires K1 relay to trigger a warning device when tail-gating is sensed.

•

Interlock with memory- allows Mega Arm to open a slide/swing gate first then raises arm.

•

Break away mounting design for the 12 -15 foot by 3 "tubular aluminum boom arm.

•

All rust proof aluminum construction with white powder coat baked on enamel.

•

Molded Polyethylene UV stabilized cover never needs wax or paint

•

Direct drive gear reducer eliminates many parts that might otherwise fail.

•

Microprocessor (RISC) based electronics with watch dog reset timer.

•

State of the art MOSFET motor drive technology, NO contactors or relays.

•

Dynamic motor braking to preserve arm positioning.

•

Soft start and stop in open and close travel motions.

•

No limit switches to fail-uses magnetic (Hall Effect) sensors to monitor arm position.

•

Maximum Run Timer for motor (MRT) with anti-tamper protection in closing direction.

•

Each unit configurable as master or slave operator.

•

Safe 24 VDC low voltage motor and control wiring.

•

Open architecture PCB with space for OVERDRIVE CPU for future expanded options.

•

LED diagnostic center for easy on-site trouble shooting.

•

Closing timer adjustable from 1-33 seconds with on / off selection.

•

Tranzorb diodes on all inputs for protection against transient voltage spikes.

•

Capable of being powered by 120 VAC, 220 VAC or Solar power, standard.

•

Duplex outlet gives convenient supply of 120 VAC for transformers and 120 VAC accessories.

•

10

year perforation warranty on cover and chassis with

2

years on electronics and mechanism.

INSTALLATION PROCEDURE

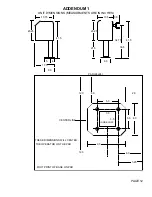

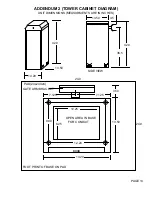

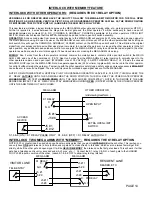

CONCRETE PAD

The concrete pad for operator mounting should be approximately 24"x24"x24" in order to provide adequate

weight and structure to insure proper and stable operation. Pad should be 6" above finished grade or even with

top of curb if one is present.

(NOTE: PAD SHOULD ALWAYS GO BELOW FROST LINE IN REGIONS

WHERE GROUND WILL FREEZE!!)

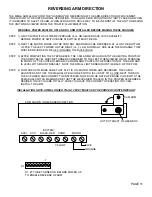

ANCHORS (MOUNTING UNIT)

Proper anchors for fastening operator to pad will be a 1/2"x6" wedge anchor patterned to match the mounting

base of the unit. They should be installed with approximately 1.25" showing above concrete surface in order to

allow for the 1/2” thick base plate as well as washers for leveling.

PAGE 1