6

INSTALLATION OF WINCHES, SELF-RETRACTING LIFELINES (

SRL's

), WORK POSITIONING AND FALL-ARREST

DEVICES NOT MANUFACTURED BY CAPITAL SAFETY GROUP

Your T-1000 TRIPOD SYSTEM can be used as a support structure for various types of safety devices.

Some of these can mount directly to the anchor point at the top of the tripod head, while others may require an adapter

bracket available from your dealer. Any accessories being used for the hoist

MUST BE

installed, inspected, maintained

and operated according to the manufactures instructions. All installations

MUST BE

approved to local standards by a

qualified engineer.

INSPECTION OF EQUIPMENT PRIOR TO USE.

- Check all structural parts for damage: dents, cracked welds bend or crushed tubes. Minor cosmetic damage will not

affect the structural integrity of the hoist, but any seriously damaged parts

MUST BE

repaired or replaced before using

the hoist.

- Check all hardware ( pins, tri-screws, adjuster screws, nuts, bolts, pulleys, rollers and winch brackets) for damaged

threads, bend, damaged or missing fasteners, loose fasteners. Check all pulleys and rollers for chips, grooves and

excessive wear. Ensure that all pulleys and rollers turn freely.

- Inspect all equipment for missing, damaged or otherwise illegible warning stickers. Any damaged, missing or

otherwise illegible stickers

MUST BE

replaced before using hoist.

- If you are using Digital Series Winches with your hoist, inspect the winch and cable as outlined in the "maintenance

and inspection" section of the Digital Series Winch operators manual.

- Any additional winches, self-retracting lifelines (SRL's), work positioning or fall-arrest equipment being used with

your T-1000 Tripod System

MUST BE

installed, inspected, maintained and operated according to the manufactures

instruction.

- Report any problems with the equipment to your supervisor and

DO NOT USE

the equipment until it has been

repaired or replaced.

INSPECTION / MAINTENANCE SCHEDULE

DAILY ( BEFORE EACH USE) :

(SEE ABOVE) INSPECTION OF EQUIPMENT PRIOR TO USE

WEEKLY:

Perform a complete visual inspection of equipment as outlined in " Inspection of Equipment Prior to Use".

Clean equipment as required, to thoroughly inspect all welds, labels, pins, fasteners, pulleys, rollers, brackets and parts.

Record all findings on a copy of the "hoist inspection log". If any problems are found with the equipment

DO NOT USE

until it has been repaired.

ANNUALLY:

Clean unit throuroghly, using a damp cloth and a mild soap solution. Perform a complete visual

inspection as described in section(F) " Inspection of Equipment Prior to Use" Record all findings on a copy of the "hoist

inspection log". If any problems are found with the equipment

DO NOT USE

until it has been repaired.

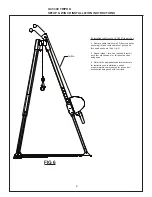

T-300/T-1000 TRIPOD SYSTEM

SETUP AND WINCH INSTALLATION INSTRUCTIONS