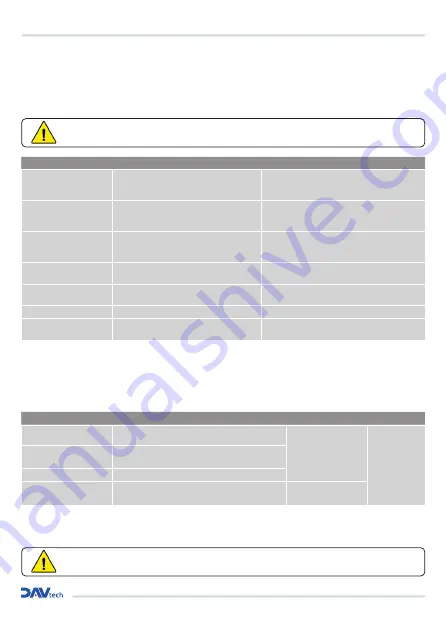

FAULT

POSSIBLE CAUSE

REMEDY

The needle metering

valve switches but no

lubricant is ejected

The feed pump is not supplying

lubricant

Consult the operating manual for the

feed pump

The needle metering

valve switches but no

lubricant is ejected

Material pressure too low

Increase pump pressure

The dispensing valve is

leaking

The control air pressure/counter-

pressure of the spring is too low

Increase the control air pressure,

reduce the material pressure, install

a stronger spring

The dispensing valve is

leaking

Defective seals

Replace seals

Air in the system

Air pockets in the grease container

Air pockets in the hoses

Loosen supply hose. Bleed system.

Reconnect supply hose.

Leaky valve

Defective seals

Replace seals

Irregular dispensing

No constant grease and air

Upstream installation of optional material

pressure regulator MDR

WHEN

WHAT

HOW

WHO

Weekly

Check valve for tightness

Visual

Qualified

personell

Weekly

Check all threaded connections and fittings

for leaks

Monthly

Check seals for damage and wear

Annually

Complete maintenance

Dismantle, clean and

replace seals

TRAINING OF PERSONNEL

Only trained and instructed personnel who have read and understood all points in the operating instructions may work on

the product. The personnel must also be able to control the operating states, and identify and implement the interrelated

safety aspects. Personnel in training may only work on the product under the supervision of qualified personnel.

5 TROUBLESHOOTING, FAULT RESOLUTION

6 MAINTENANCE

Needle metering valves are precision instruments that are not susceptible to faults, given proper handling, and operate

largely without maintenance, assuming that the application material is generally processed in clean condition, not

contaminated by foreign particles. We recommend the following maintenance intervals to optimise the service life:

The specified maintenance intervals are for single shift operation. Maintenance has to be carried out more often

depending on the field of application, medium and in case of operation in more than one shift.

CAUTION

All of the faults described below may only be resolved by trained, qualified personnel.

CAUTION All work on the system is basically only to be carried out when it is at a standstill. The pneumatic

and hydraulic systems have to be de-pressurised. The pressure gauges have to show 0 bar.

Installation and maintenance guide