VLASE

TM

IR

80

7

7.2 MAINTENANCE

The ordinary maintenance program foresees only simple operations. Some operations consist in a mere

“check” of the operating condition.

The maintenance activities must be done in compliance with the legal prescriptions regarding the safety

rules during the operations.

The following parts/functions have to be controlled:

MAINTENANCE PROGRAM

COMPONENT OR FUNCTION

TYPE OF OPERATION

INTERVALS

F-Theta Scan Lens

Check / Clean

Weekly: wipe gently with a dry cloth (

or

soaked in high purity isopropyl alcohol

)

or clean it with air blowing

Rack Air filters

Clean / Replace

Every 3 months (according to the

environment and frequency of use)

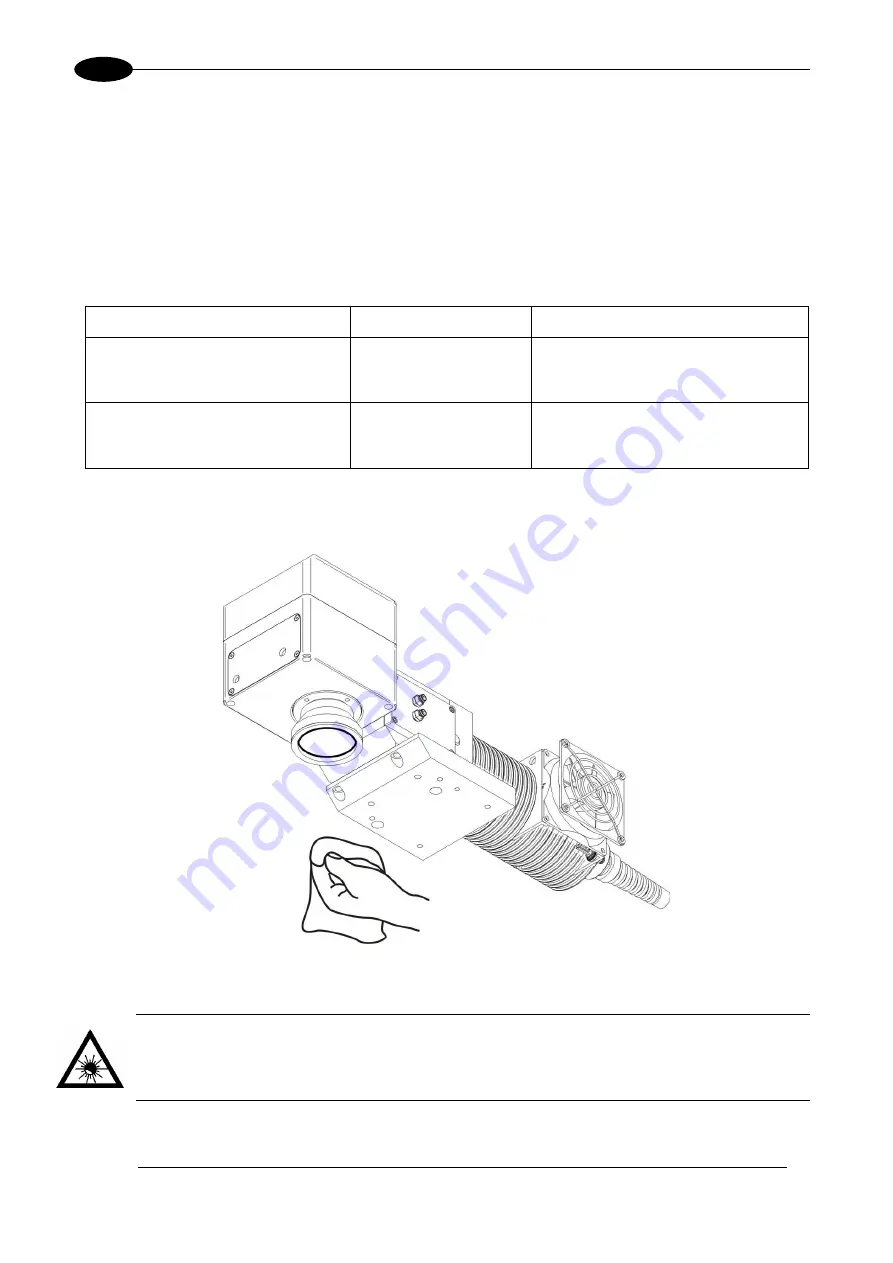

7.2.1 F-THETA SCAN LENS CLEANING PROCEDURE

Figure 65: Cleaning F-Theta lens.

WARNING!

Before cleaning the F-Theta scan lens, the marking system MUST be set to SAFE mode:

1- Disable

EXT_ENABLE_A

and

EXT_ENABLE_B

.

2- Disable

INTERLOCK_A

and

INTERLOCK_B

.

Содержание VLASE IR 1PWX-TLS2

Страница 1: ...USER S MANUAL VLASETM IR ...

Страница 34: ...VLASETM IR 34 2 2 6 CONNECTION EXAMPLES Figure 27 Connection examples ...

Страница 59: ...USE AND OPERATION 59 4 Edit Filling properties such as filling type interline etc using the Properties browser ...

Страница 78: ...VLASETM IR 78 6 6 4 RACK HANDLES Handles for rack fastening are available on request Figure 64 Rack handles ...

Страница 85: ...85 EXTERNAL LABEL PLACING Figure 67 Positioning of external labels rack ...

Страница 86: ...86 Figure 68 Positioning of external labels resonator ...

Страница 90: ...90 BLOCK DIAGRAM VLASETM SAFETY LOGIC DETAILS FOR AUTOMATIC PRODUCTION LINE ...

Страница 108: ...108 APPENDIX G MECHANICAL DRAWINGS ...

Страница 109: ...109 NOTE Please refer to Datalogic website for detailed drawings ...

Страница 112: ......