49

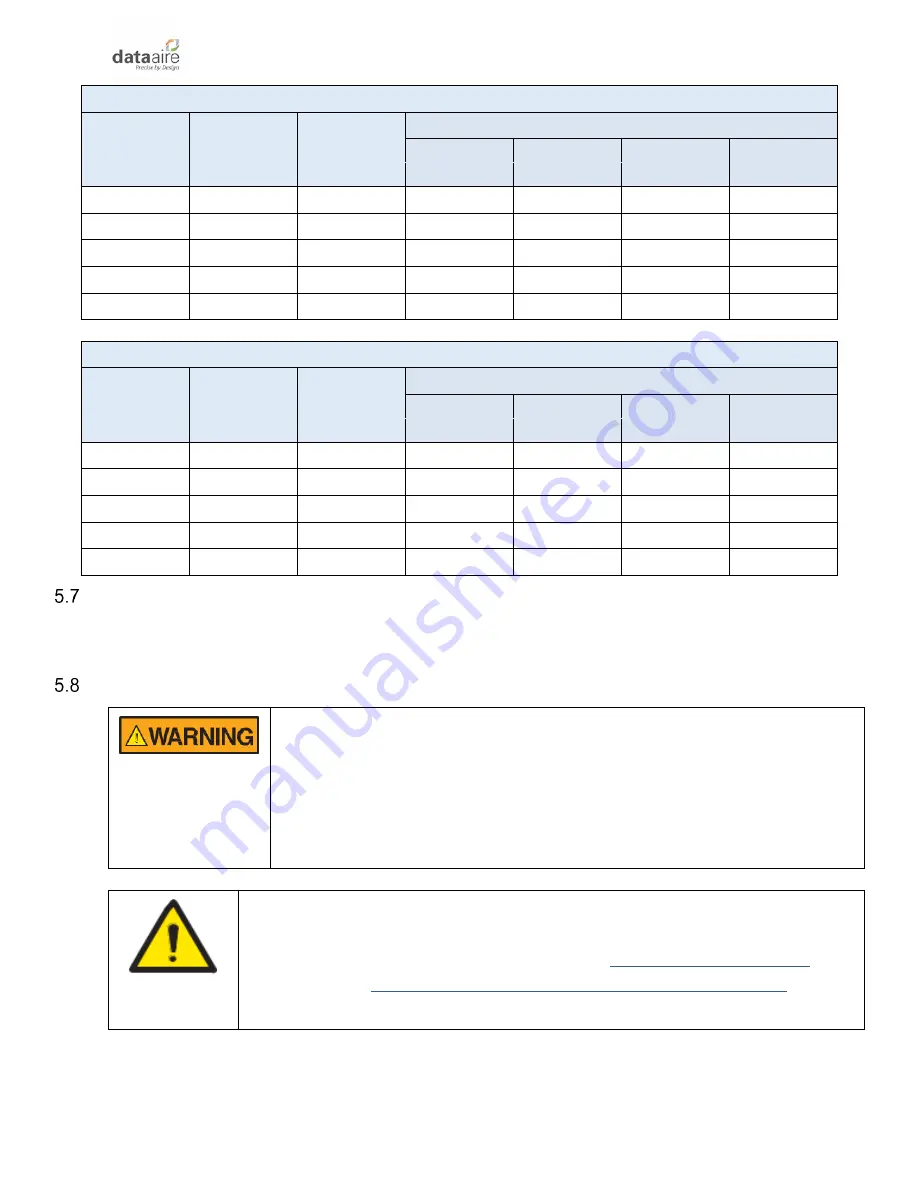

Table 12 Liquid Line Multiplier for

R-410A

at Various Line Lengths

Liquid Line

Nominal Size

(inches)

Liquid Line

Size OD

(inches)

Multiplier

Equivalent Feet (Meters)

50

100

150

200

(15.2)

(30.5)

(45.7)

(61.0)

3/8

1/2

0.067

3.35

6.71

10.06

13.41

1/2

5/8

0.108

5.38

10.76

16.13

21.51

5/8

3/4

0.154

7.70

15.40

23.10

30.80

3/4

7/8

0.239

11.95

23.90

35.85

47.80

1

1 1/8

0.380

19.02

38.04

57.06

76.08

Table 13 Liquid Line Multiplier for

R-407C

at Various Line Lengths

Liquid Line

Nominal Size

(inches)

Liquid Line

Size OD

(inches)

Multiplier

Equivalent Feet (Meters)

50

100

150

200

(15.2)

(30.5)

(45.7)

(61.0)

3/8

1/2

0.072

3.58

7.17

10.75

14.33

1/2

5/8

0.115

5.75

11.49

17.24

22.99

5/8

3/4

0.165

8.23

16.46

24.69

32.92

3/4

7/8

0.255

12.77

25.54

38.31

51.08

1

1 1/8

0.407

20.33

40.65

60.98

81.31

Component Functional Test

Critical components can be functionally verified by using the manual mode of the Mini-dap4. See Mini-

dap4 User Manual for details regarding how to use Menu I

– Manual Control (Service Level).

Charging Procedures

WARNING:

If the system is charged from a vacuum, the preheating of the

compressor is not necessary. But if starting a compressor that has not

been charged from a vacuum, the crankcase heater must be energized

for a minimum of 12 hours to reduce the possibility of liquid slugging on

startup. Failure to energize the crankcase heater could result in

compressor damage.

NOTICE

Prior to refrigerant charging, the proper tools and/or equipment must

be available, and the system vacuum and moisture removal procedure must

have been carried out. Refer to Section

5.3 Triple Evacuation and Dehydration Procedure

charging the system.

Содержание DAPA-2.5

Страница 1: ......

Страница 81: ...DAP IOM_10 2022...