17

www.Daniel.com

USER MANUAL

2

Operating conditions and

specifications

2.1

Operating conditions for the control valve

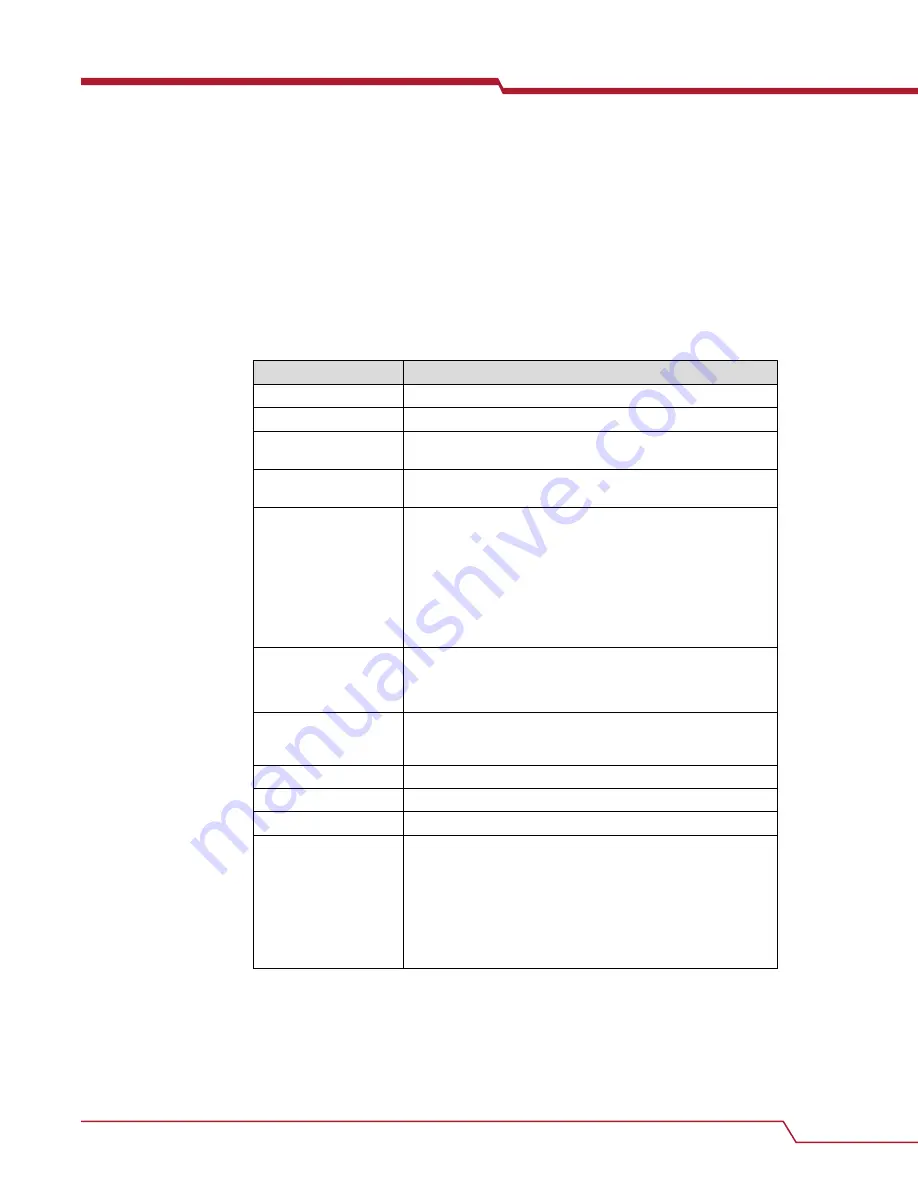

Table 2-1: Operating conditions for the control valve

Condition type

Description

Fluid phase

Liquid

Process temperature

-20° F to 150° F (-29° C to 66° C)

Optional process

temperature

-50° F to 400° F (-46° C to 205° C )

Fluid velocity

Operational recommended flow velocity up to 30 ft/sec, beyond this

point will result in a high pressure drop and increased wear.

Fluid(s) controlled

•

Low/Medium viscosity crude oils and condensates

•

Refined products and intermediates (ie:

gasoline, diesel, kerosene,

light fuel oils, jet fuel, LPG, butanes, naphtha, alkylate, reformate,

straight run gasoline, cat-cracked gasoline

)

•

Petrochemicals (ie:

benzene, toluene, xylenes, cumene, olefins,

pyrolysis gasoline

)

•

Natural gas liquids

Viscosity limits on valves

and valves with pilots

•

Maximum valve viscosity is 8800 Cst

•

Maximum viscosity for valves with pilots is 440 Cst due to

response time of high viscosity pilot

Differential pressure

The maximum allowable differential pressure across a control valve is

6894 kPa (1,000 psi). Consult factory for location of first shut down

valve.

Atmospheric pressure

Absolute

Sizes (NPS)

2, 3, 4, 6, 8,10,12,16

Pressure class (ANSI)

150, 300, 600

Maximum safe working

temperature range

•

15° F to 400° F (-26° C to 204° C)

•

Using FKM O-rings

•

Temperature range is dependent of O-ring T

min

and T

max

•

Max temperature of valves with solenoid pilots is standard -20° F

to 150° F (-29° C to 66° C) (if applicable), Optional 250° F (121° C)

•

Consult the factory for other safe working temperatures

User manual

Operating conditions and specifications

P/N 3-9008-553

November 2020

User manual

19