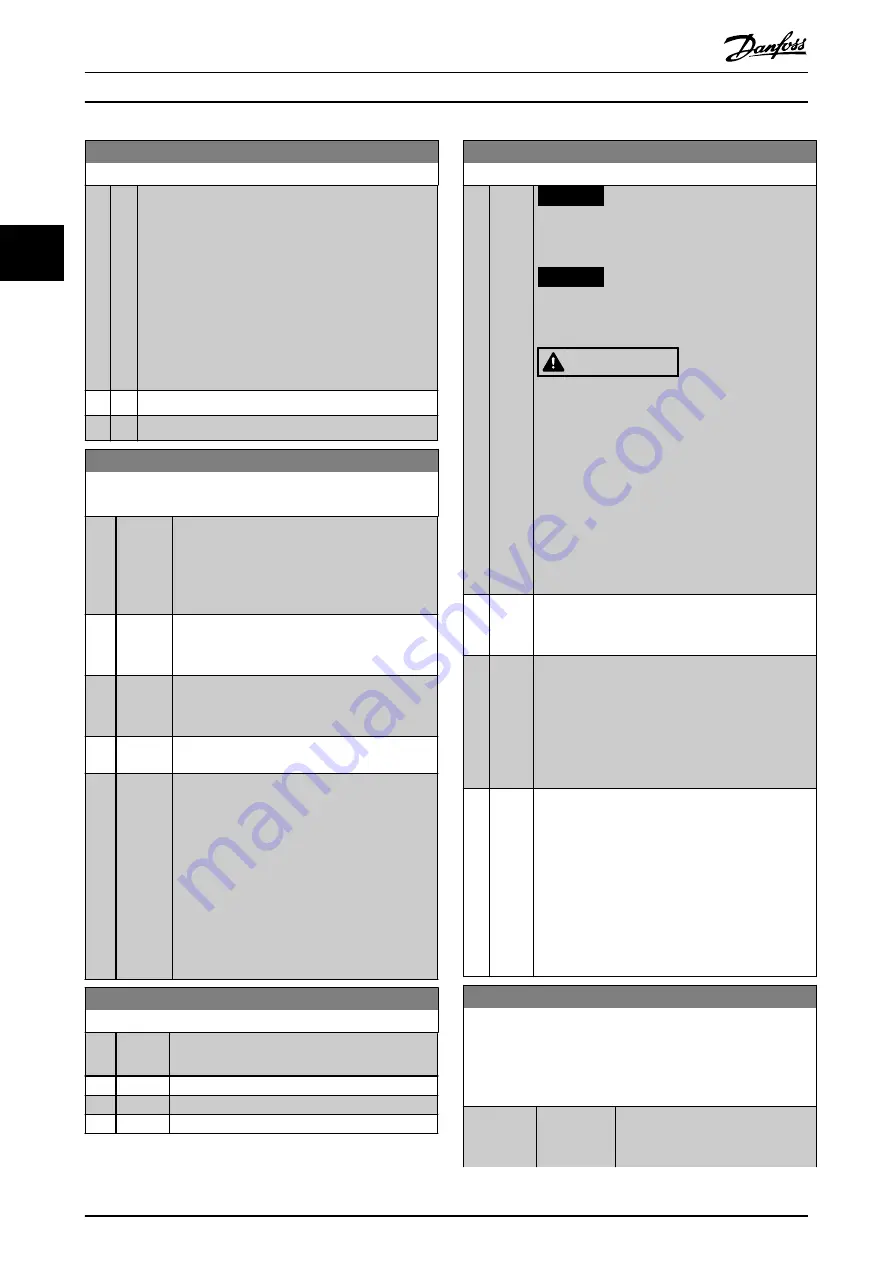

14-51 DC-Link Compensation

Option: Function:

The rectified AC-DC voltage in the frequency converter's

DC link is associated with voltage ripples. These ripples

can increase in magnitude with increased load. These

ripples are undesirable because they can generate

current and torque ripples. A compensation method is

used to reduce these voltage ripples in the DC link. In

general, DC-link compensation is recommended for

most applications, but pay attention when operating in

field weakening as it can generate speed oscillations at

the motor shaft. In field weakening, turn off DC-link

compensation.

[0] Off Disables DC-link compensation.

[1] On Enables DC-link compensation.

14-52 Fan Control

Select minimum speed of the main fan.

Option:

Function:

[0]

*

Auto

Select

[0] Auto

to run fan only when internal

temperature in frequency converter is in range

35

°

C (95

°

F) to approximately 55

°

C (131

°

F).

Fan runs at low speed below 35

°

C (95

°

F), and

at full speed at approximately 55

°

C (131

°

F).

[1]

On 50%

The fan always runs at 50% speed or above. The

fan runs at 50% speed at 35

°

C (95

°

F), and at

full speed at approximately 55

°

C (131

°

F).

[2]

On 75%

The fan always runs at 75% speed or above. The

fan runs at 75% speed at 35

°

C (95

°

F), and at

full speed at approximately 55

°

C (131

°

F).

[3]

On

100%

The fan always runs at 100% speed.

[4]

Auto

(Low

temp

env.)

This option is the same as

[0] Auto

, but with

special considerations around and below 0

°

C

(32

°

F). In option

[0] Auto

there is a risk that the

fan starts running around 0

°

C as the frequency

converter detects a sensor fault and thus

protects the frequency converter while reporting

warning 66, Heat sink Temperature Low

. Option

[4]

Auto (Low temp env.)

can be used in very cold

environments and prevents the negative effects

of this further cooling and avoids

warning 66,

Heat sink Temperature Low

.

14-53 Fan Monitor

Option:

Function:

Select the frequency converter action if a fan

fault is detected.

[0]

Disabled

[1]

*

Warning

[2]

Trip

14-55 Output Filter

Option:

Function:

NOTICE

This parameter cannot be adjusted while the

motor is running.

NOTICE

Reset the frequency converter after selecting

[2] Sine-Wave Filter Fixed

.

CAUTION

OVERHEATING OF FREQUENCY

CONVERTER

When using sine-wave filters, there is a risk

of overheating of the frequency converter,

which can result in personal injury and

equipment damage.

Always set

to

[2] Sine-wave fixed

when using a sine-wave

filter.

Select the type of output filter connected.

[0]

*

No

Filter

This is the default setting and should be used with

dU/dt filters or high frequency common mode (HF-

CM) filters.

[1] Sine-

Wave

Filter

This setting is only for backwards compatibility. It

enables operation with flux control principle when

parameter 14-56 Capacitance Output Filter

and

parameter 14-57 Inductance Output Filter

are

programmed with the output filter capacitance and

inductance. It does not limit the range of the

switching frequency.

[2] Sine-

Wave

Filter

Fixed

This parameter sets a minimum allowed limit to the

switching frequency and ensures that the filter is

operated within the safe range of switching

frequencies. Operation is possible with all control

principles. For flux control principle, program

parameter 14-56 Capacitance Output Filter

and

parameter 14-57 Inductance Output Filter

(these

parameters have no effect in VVC

+

and U/f). The

modulation pattern is set to SFAVM, which gives the

lowest acoustic noise in the filter.

14-56 Capacitance Output Filter

Compensation function of the LC filter requires the per phase

equivalent star-connected capacitance of the filter (3 times the

capacity between 2 phases when capacitance is delta

connection).

Range:

Function:

Size related

*

[0.1 - 6500

uF]

Set the capacitance of the output

filter. The value can be found on the

filter label.

Parameter Descriptions

VLT

®

AutomationDrive FC 301/302

198

Danfoss A/S © 10/2018 All rights reserved.

MG33MP02

3

3

Содержание VLT AutomationDrive FC 302

Страница 2: ......